Production equipment and production process for insoluble sulphur

A production equipment and sulfur technology are applied to the production process of the above production equipment, the production equipment of insoluble sulfur, and the field of sulfur production equipment, which can solve the problems of large reaction space, low reaction uniformity, large energy consumption, etc. The effect of uniformity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

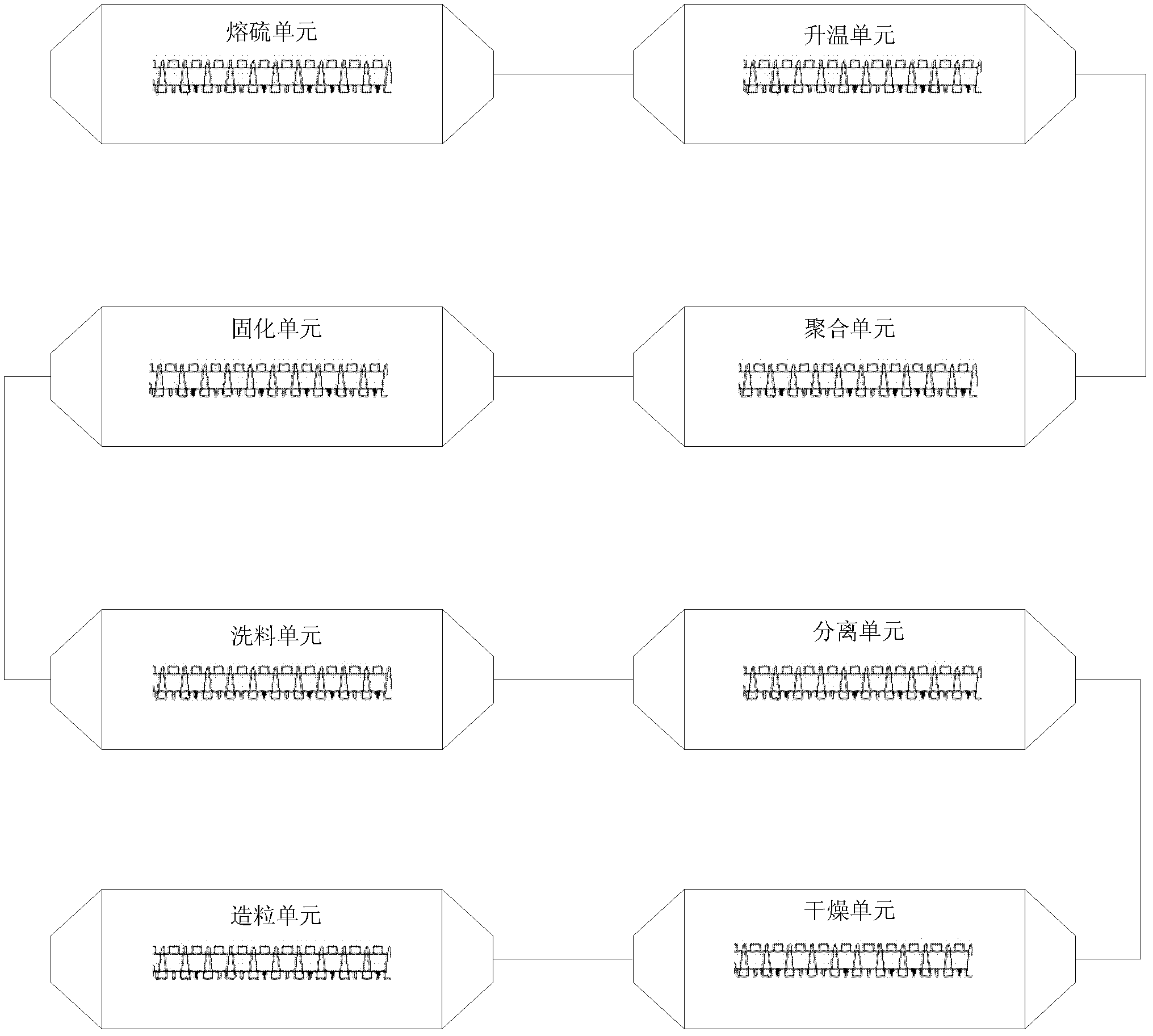

[0048] see figure 1 , the present invention discloses a production equipment for insoluble sulfur, the equipment comprises sequentially connected sulfur melting unit, heating unit, polymerization unit, solidification unit, washing unit, separation unit, drying unit, granulation unit; One or more of the sulfur unit, heating unit, polymerization unit, solidification unit, washing unit, separation unit, drying unit, and granulation unit includes one or more hollow paddle mechanisms.

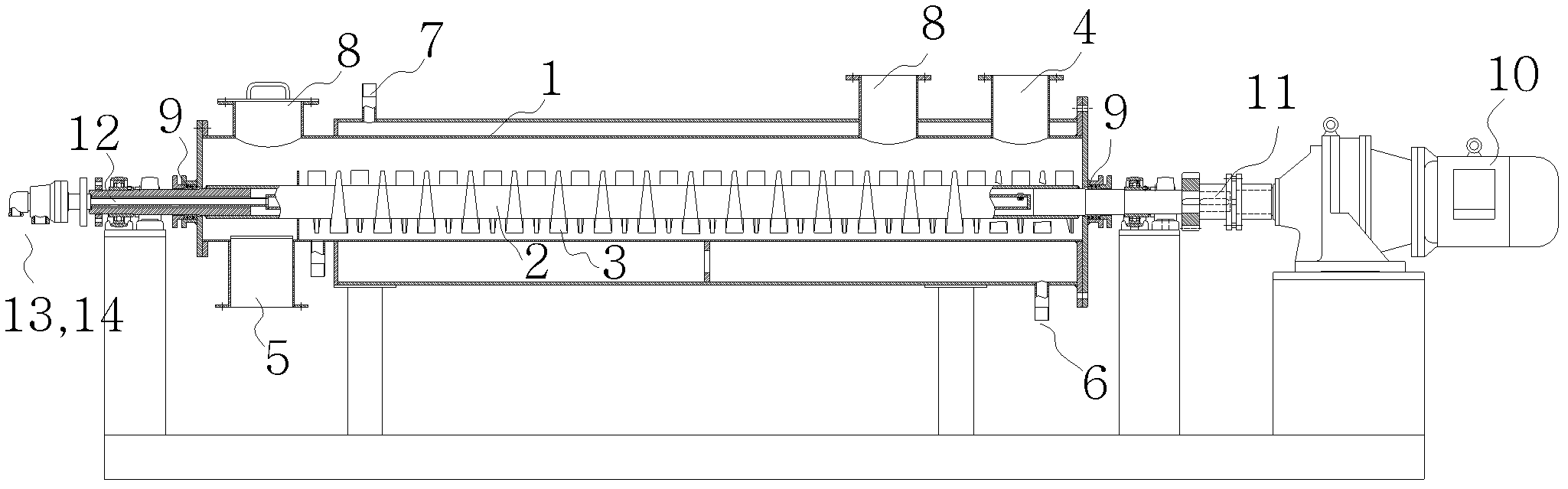

[0049] see figure 2 , figure 2 A structural schematic diagram of the above-mentioned hollow paddle mechanism is disclosed. The hollow blade mechanism includes a housing 1 , at least one hollow shaft 2 arranged in the housing 1 , and several hollow blades 3 arranged on the hollow shaft 2 .

[0050] The housing 1 is provided with one or more inert gas input ports 8 , through which the inert gas input devices are connected to an inert gas input device, and the inert gas is input into the control h...

Embodiment 2

[0068] In this embodiment, the production equipment for insoluble sulfur includes a sulfur melting unit, a heating unit, a polymerization unit, a solidification unit, a washing unit, a separation unit, a drying unit, and a granulation unit connected in sequence; the sulfur melting unit, the heating unit, One or more of the polymerization unit, curing unit, washing unit, separation unit, drying unit, and granulation unit includes one or more hollow paddle mechanisms;

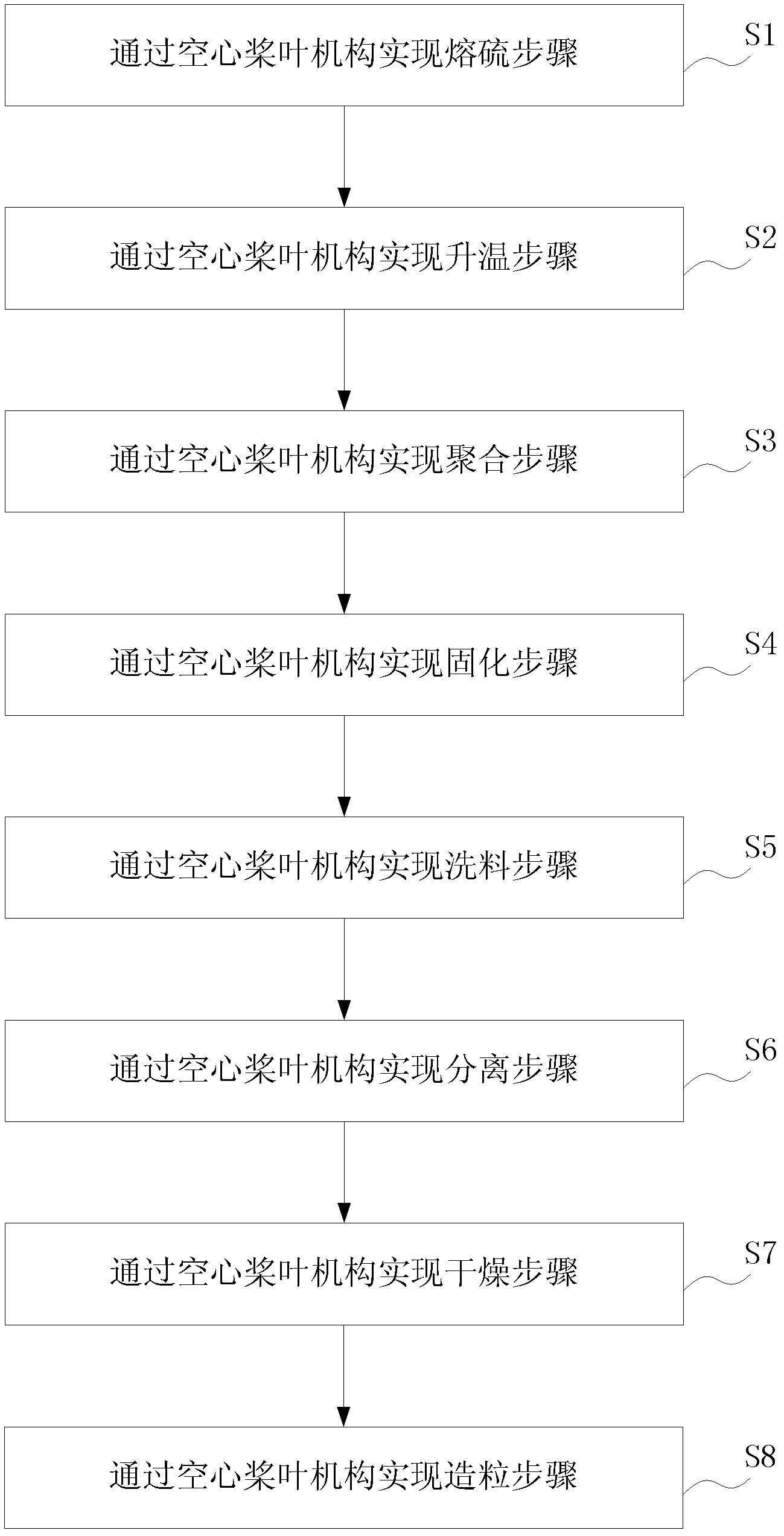

[0069] The production process of the insoluble sulfur production equipment includes the following steps: a sulfur melting step, a heating step, a polymerization step, a solidification step, a material washing step, a separation step, a drying step, and a granulation step. One or more of the sulfur melting step, heating step, polymerization step, solidification step, material washing step, separation step, drying step and granulation step are realized in the hollow paddle mechanism.

Embodiment 3

[0071]The difference between this embodiment and Embodiment 1 is that in this embodiment, the production equipment further includes cryogenic crushing equipment for insoluble sulfur. The equipment includes an inert substance conveying device, an inert substance spraying device, a feeding bin, a feeder, a mechanical crushing host, an induced draft fan, a cyclone separator, a screener, a discharge bin, and an inert gas circulation loop; the inert substance spraying device Connect the inert material conveying device, and spray the low-temperature inert material in the feeding bin; the feeding bin is connected with the feeder, and the feeder transports the insoluble sulfur into the mechanical crushing host for crushing; the induced draft fan is set at the outlet of the mechanical crushing host, and the mechanical grinding host Between the cyclone separator; the inlet of the sieve is connected to the cyclone separator, and the outlet is connected to the discharge bin; the crushing e...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com