Pull-jacking type lengthwise graphitization furnace

A graphitization furnace and top-pulling technology, applied in inorganic chemistry, carbon compounds, chemical instruments and methods, etc., can solve the problem of uneven force on both ends of the carbon blank column, unbalanced double-sided push pressure, single-sided pressure attenuation and other problems, to achieve the effect of reducing the investment in civil construction, good pressure stability, and rapid response

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

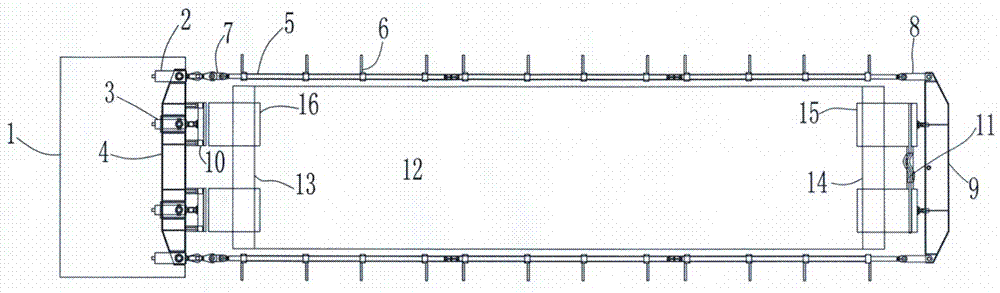

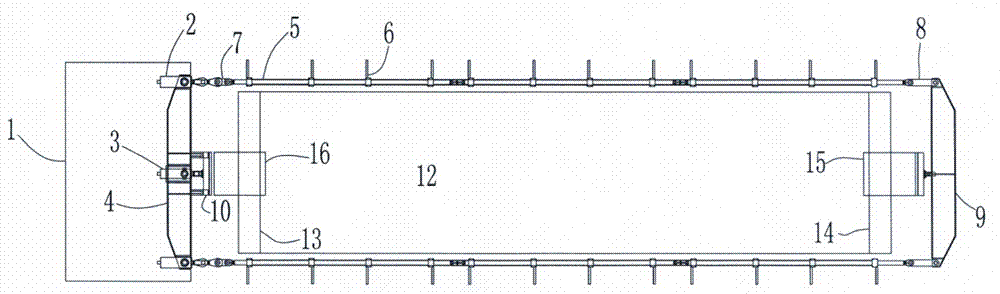

[0011] The following will be described in conjunction with the accompanying drawings and specific embodiments. see figure 1 , in the structure of the top-drawing series graphitization furnace, the furnace head transmission station car 1 carries the power transmission equipment, two thrust cylinders 3 and two tension cylinders 2, and undertakes the mobile transportation of the power transmission equipment and four cylinders. Both the thrust cylinder and the tension cylinder are telescopic hydraulic cylinders. Two pulling oil cylinders 2 and two thrust oil cylinders 3 are fixed on the head beam 4 of the burner trolley in a hinged manner.

[0012] The tension oil cylinder 2 is connected to the burner connection mechanism 7 through a hinged connection, and the mechanism is formed by fixing the joint bearing on the insulating thrust plate. The tie rod 5 is placed on the tie rod support mechanism 6 welded by the channel steel to be able to slide freely, and at the same time, it is...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com