Vacuum device for platinum passage

A technology of negative pressure device and platinum channel, which is applied in the field of negative pressure device, can solve the problems of reducing the quality of glass liquid, prolonging the clarification time of glass liquid, and the gas cannot be discharged out of the channel in time and effectively, so as to shorten the clarification time and be easy to disassemble Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

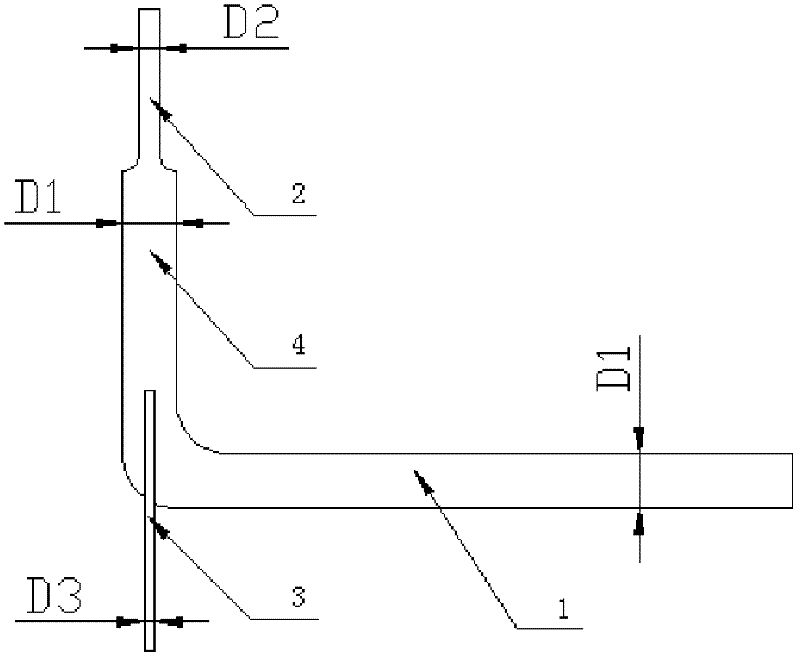

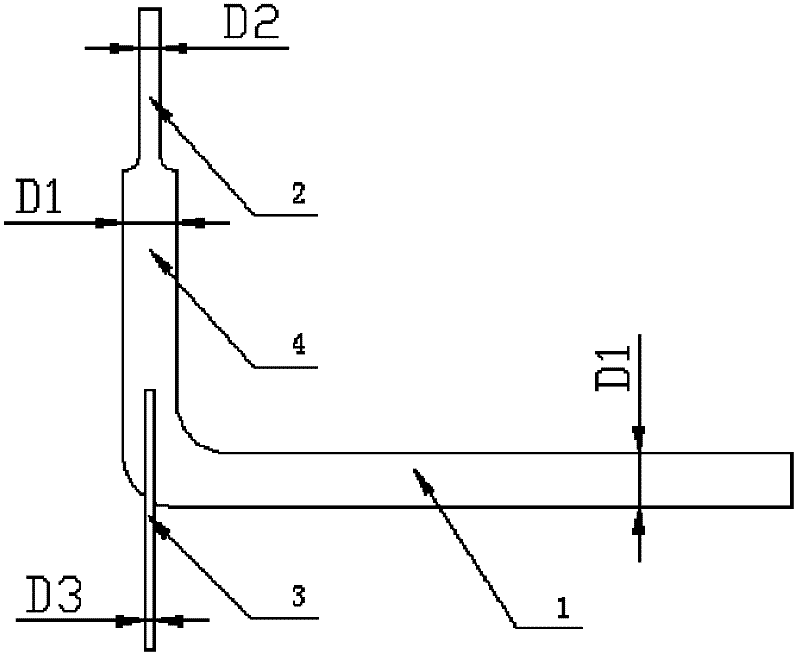

[0010] The present invention is described in further detail below in conjunction with accompanying drawing:

[0011] See attached figure 1 , tube 1 and tube 2 have the same diameter and are welded together, tube 4 and tube 2 are welded together, the diameter D2 of tube 2 must be smaller than the diameter D1 of tube 4, tube 3 is welded at the transition between tube 1 and tube 4, and tube 3 extends The height of the inlet pipe 4 must exceed the height of the upper edge of the pipe 1.

[0012] One side of pipe 1 is welded with pipe 4, and the other side extends into the vent hole outside the clarification pipe, and is closely matched with the vent hole, and pipe 3 is passed into high-pressure air.

[0013] After the negative pressure device is activated, it is fixed on the outside of the clarification tube as a whole. The end of tube 1 extends into the edge of the clarification tube and is closely matched with the exhaust hole of the clarification tube. the height of the upper...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com