Composite decoration foam concrete building block and manufacture method thereof

A foamed concrete and block technology is applied in the field of blocks for building walls, which can solve the problems of tiles falling off, foamed concrete blocks having no decorative structure, etc., and achieves low cost, reduced labor intensity and construction cost, heat insulation and sound insulation. good effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

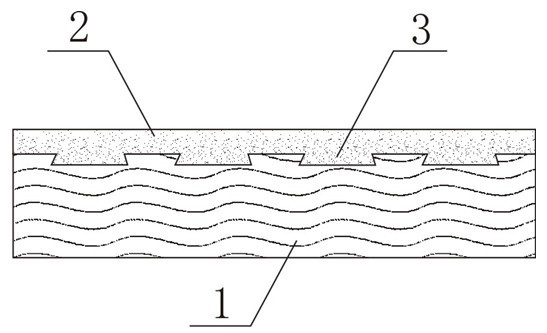

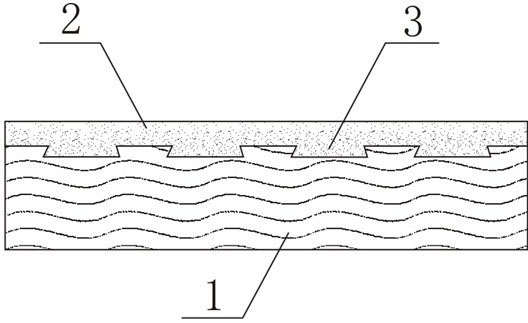

[0027] Embodiment 1: see figure 1 , a composite decorative foam concrete block, comprising a foam concrete block body 1, the side wall of the foam concrete block body 1 is compounded with a decorative panel 2; the decorative panel is provided with a connecting structure of a wedge-shaped bump or a raised line 3. Combining the decorative panel and the foam concrete block into one. The decorative panel is decorative ceramic tile, marble or artificial marble and the like.

Embodiment 2

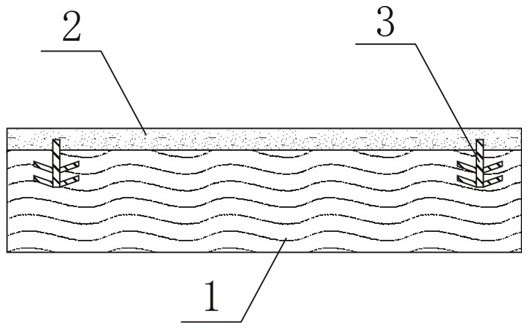

[0028] Example 2, such as figure 2 As shown, the difference from Embodiment 1 is that the connection structure is a protrusion with barbs or barbs; the connection structure is provided near the four corners of the back of the decorative panel and is integrated with the decorative panel.

Embodiment 3

[0029] Embodiment 3: Different from Embodiment 1, the connection structure is a convex nail fixed to the decorative panel through processing (figure omitted).

[0030] In addition, ceramic tiles 2 can also be compounded on two or more surfaces of the foam concrete block body 1, for walls that require double-sided or multiple-sided decoration.

[0031] A method for making a composite decorative foam concrete block, comprising the steps of:

[0032] 1) On the back of the decorative panel (such as ceramic tile), evenly set wedge-shaped bumps or convex lines, or fix protrusions with barbs or barbs on the back of the decorative panel; the decorative panel is decorative tile, marble or artificial Marble etc.

[0033] 2) At least one decorative panel with a connecting structure is placed on the side wall of the mold for pouring the foam concrete block, and then the foam concrete is poured into the mold; the weight ratio of the formula of the foam concrete is:

[0034] for...

PUM

| Property | Measurement | Unit |

|---|---|---|

| power level | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com