Production method of snowflake fabric from paster fiber and combed cotton fiber through tight, AB and nubby spinning

A production method, the technology of combed cotton, which is applied in the direction of fabrics, textiles, spinning machines, etc., can solve the problems of small patterns, lack of three-dimensional effect, and inability to fully reflect the rough style, so as to achieve cost reduction and clear lines with obvious convex and concave Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

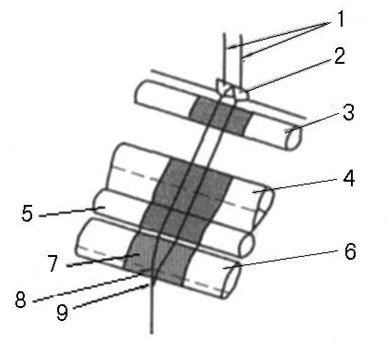

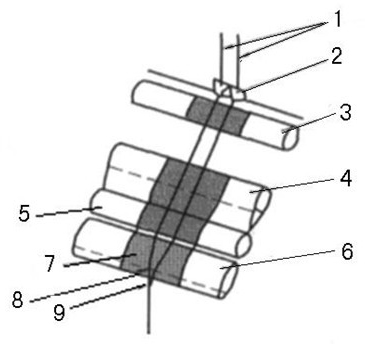

Image

Examples

Embodiment Construction

[0027] The production method of the snowflake fabric produced by compact AB slub spinning of Paiste fiber and combed cotton fiber includes the following steps in sequence: 1) spinning, 2) weaving, 3) finishing after printing and dyeing;

[0028] 1. Spinning:

[0029] 1) Preparation of combed cotton fiber to obtain roving A: Opening and cleaning machine → carding → pre-merging → coiling → combing → final merging → roving A.

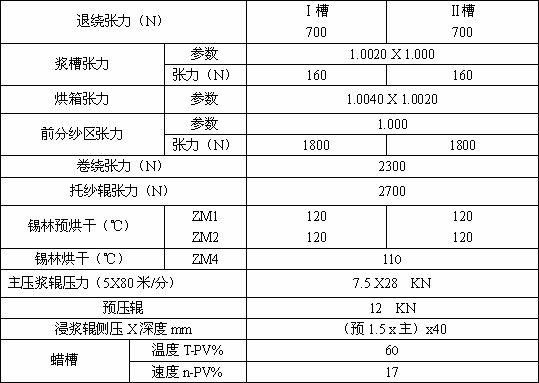

[0030] Combed cotton, select Xinjiang first-class fine-staple cotton, and its related equipment flow: A002D type cotton grabbing machine, A035 type cotton opening and mixing machine, FA025 type multi-storey cotton mixing machine, FA106 type cotton opening machine, FA161 type vibrating cotton feeder One A076F single-hand lapping machine one FA224 carding machine one FA311F pre-drawing machine one E32 type sliver and lap combining machine one E65 combing machine one HR1000 drawing frame one FA458 roving frame, the main process parameters As follows: Open an...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com