Simplifying drainage device of pulsator washing machine

A technology for drainage devices and washing machines, which is applied in washing devices, other washing machines, textiles and papermaking, etc., can solve the problems of complicated pipelines, large space occupation, low production efficiency, and many failure points, so as to reduce failure points and potential safety hazards. Reduce glue sealing points, reduce the effect of assembled parts

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

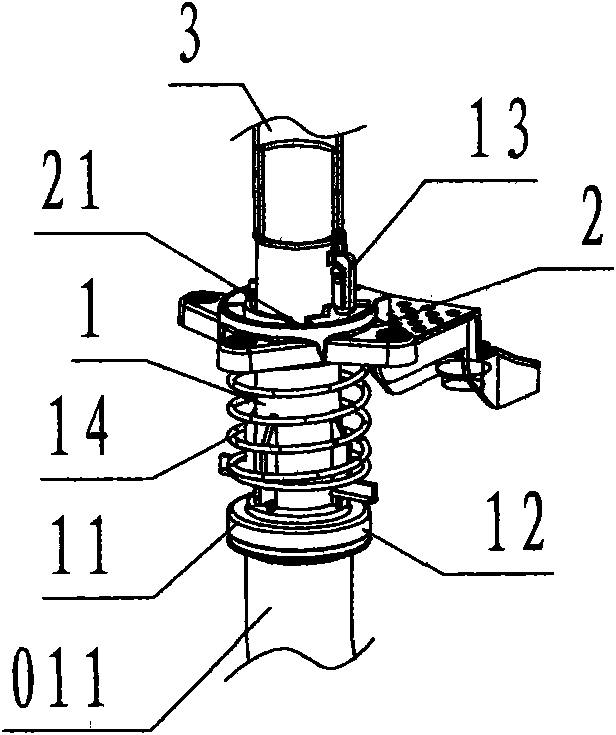

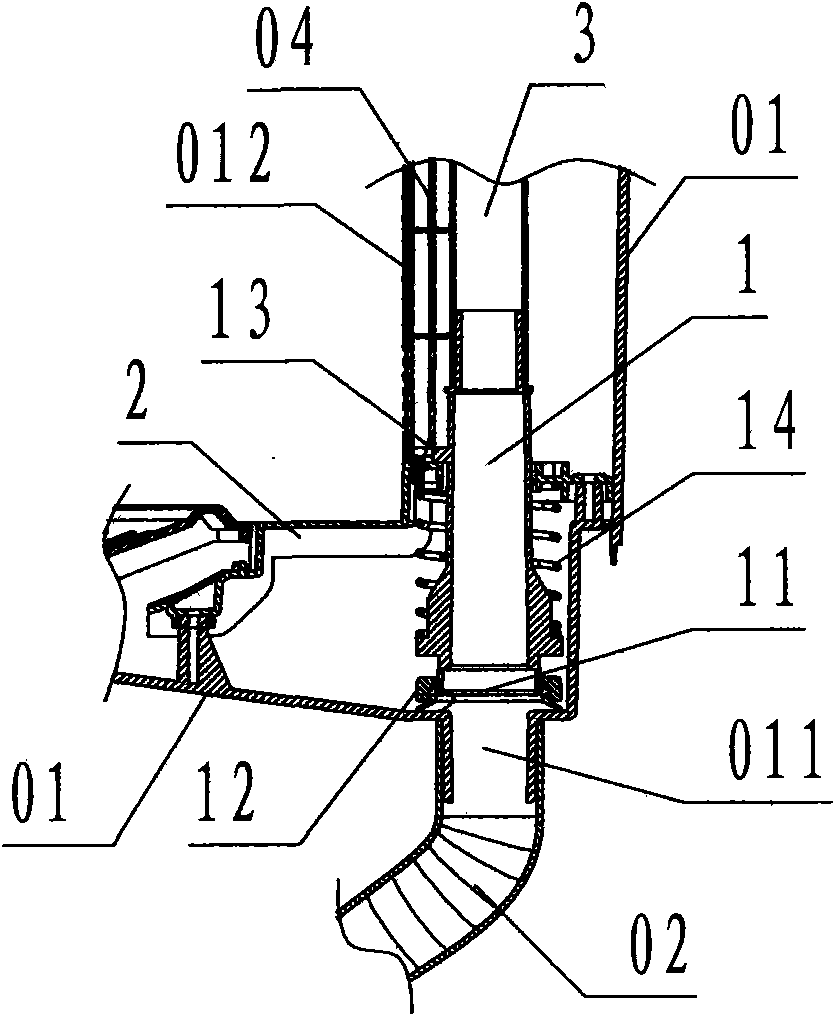

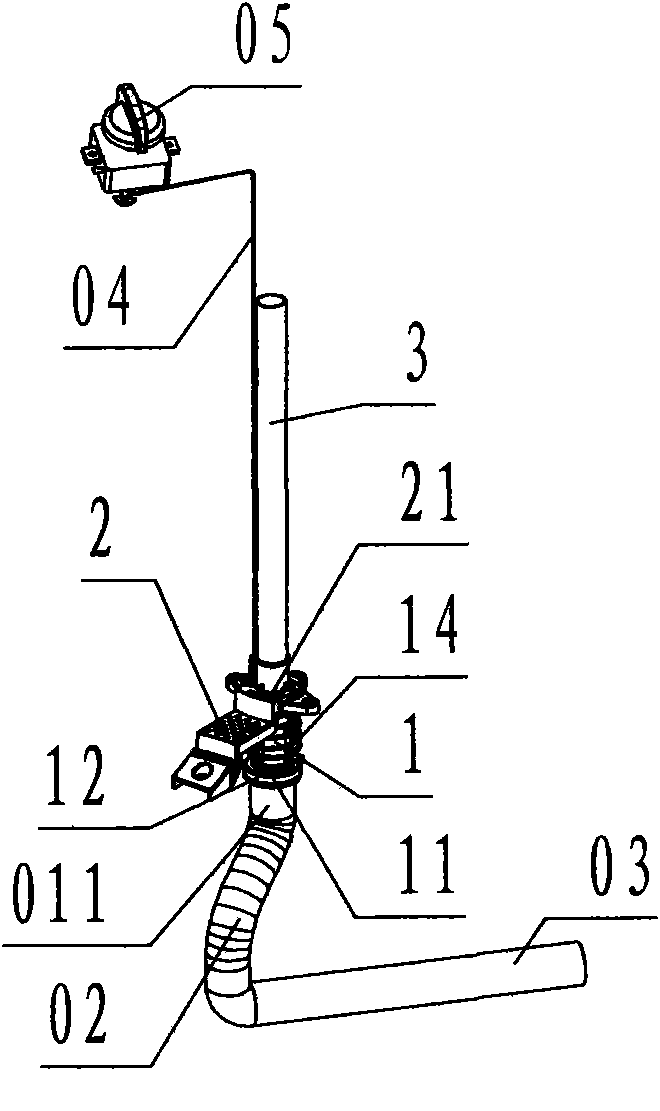

[0025] refer to Figure 1 ~ Figure 4 , a simplified drainage device for a pulsator washing machine according to the present invention, comprising a cover blocker 1, a connector 2, and an overflow pipe 3, wherein: the cover blocker 1 is from bottom to top, from bottom, middle, A cylindrical step-shaped thin-walled tubular plastic member composed of three steps with decreasing diameters. The lower step of the capping device 1 is called the plug flange 11, and the top of the plug flange 11 is symmetrically arranged around the outer wall of the middle step tube. There are four convex ribs called retaining ribs, the upper end of which stops at 1 / 3 of the height of the middle step from bottom to top, and the lower part of the retaining ribs is provided with a boss supporting spring 14, which is sleeved on the cover At the middle step of the blocking device 1, the lower end of the spring 14 is located above the boss of the retaining rib; the outer wall of the plug flange 11 is fixedl...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com