Prefabricated L-shaped retaining structure

A support structure and L-shaped technology, applied in the field of prefabricated L-shaped support structures, can solve the problems of insufficient road shoulder width to meet the requirements, large traffic interference on existing lines, and limited height of the ballast wall, so as to shorten the construction period, Conducive to the effect of stability and simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

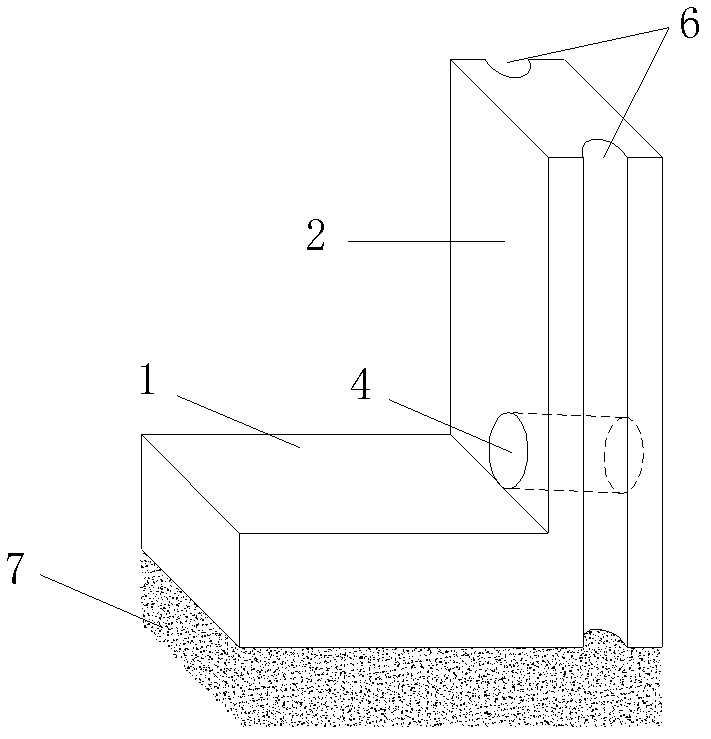

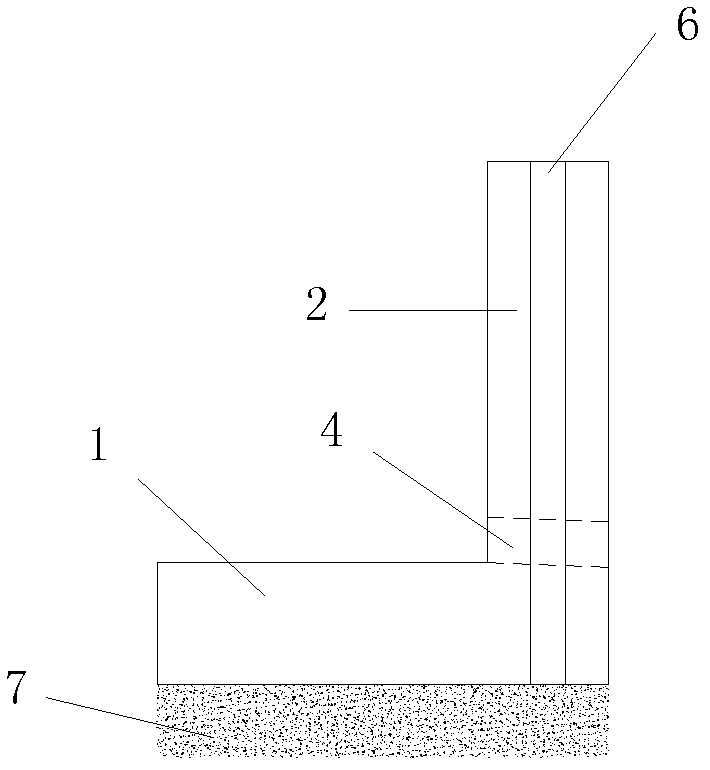

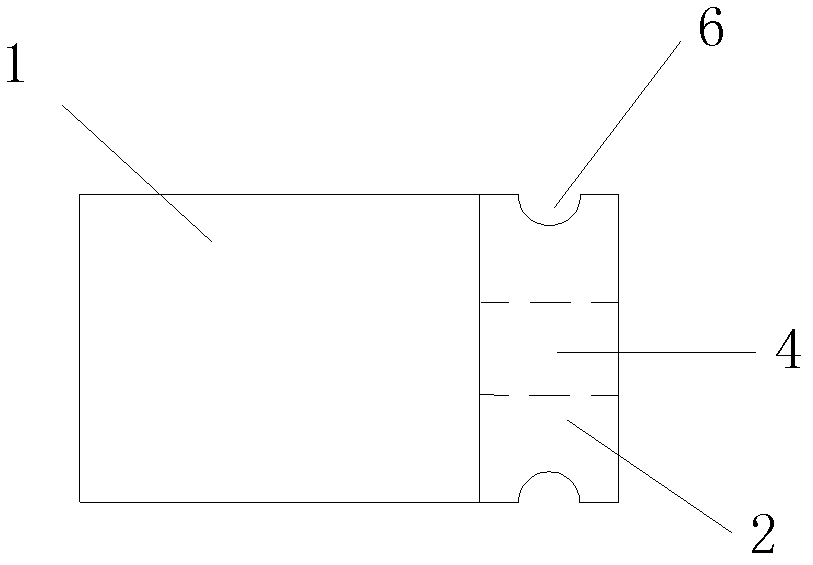

[0020] The preferred embodiment of the L-shaped support structure of the present invention is as follows: Figure 1 to Figure 8 Shown:

[0021] It includes a base plate 1, one end of the base plate 1 is connected with a straight wall 2, the height of the straight wall 2 is greater than or equal to the length of the base plate 1, and a drain hole 4 is provided at the bottom of the straight wall 1. The lower edge of the drain hole 4 is flush with the upper plane of the base plate 1, the upper surface of the base plate 1 and the inner surface of the straight wall 2 are respectively provided with hoisting rings 5, and the two sides of the straight wall 2 are respectively provided with An assembling hole 6 is arranged, and the assembling hole 6 is a semi-cylindrical hole penetrating up and down.

[0022] The bottom plate 1 and the straight wall 2 are integral prefabricated structures of reinforced concrete.

[0023] The bottom plate 1 is perpendicular to the straight wall 2 .

...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com