Assembling anchor rod or anchor cable frame

An assembled and bolted technology, used in sheet pile walls, excavation, construction, etc., can solve the problems of heavy PC lattice, poor integrity and seismic performance, and poor road conditions in the slope area, so as to ensure integrity. , The effect of strong integrity and remarkable seismic performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] The specific implementation manners of the present invention will be described in further detail below in conjunction with the accompanying drawings.

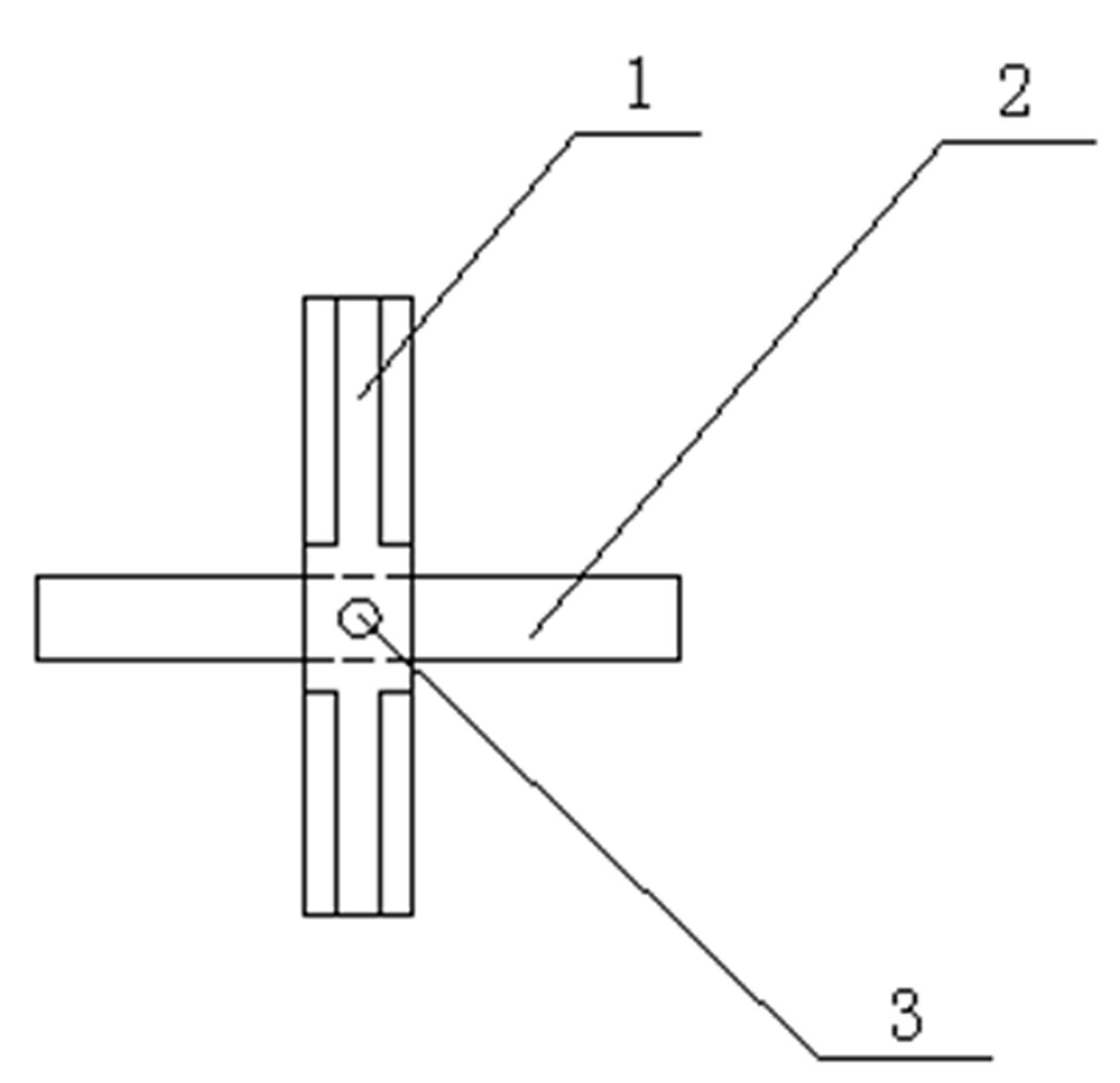

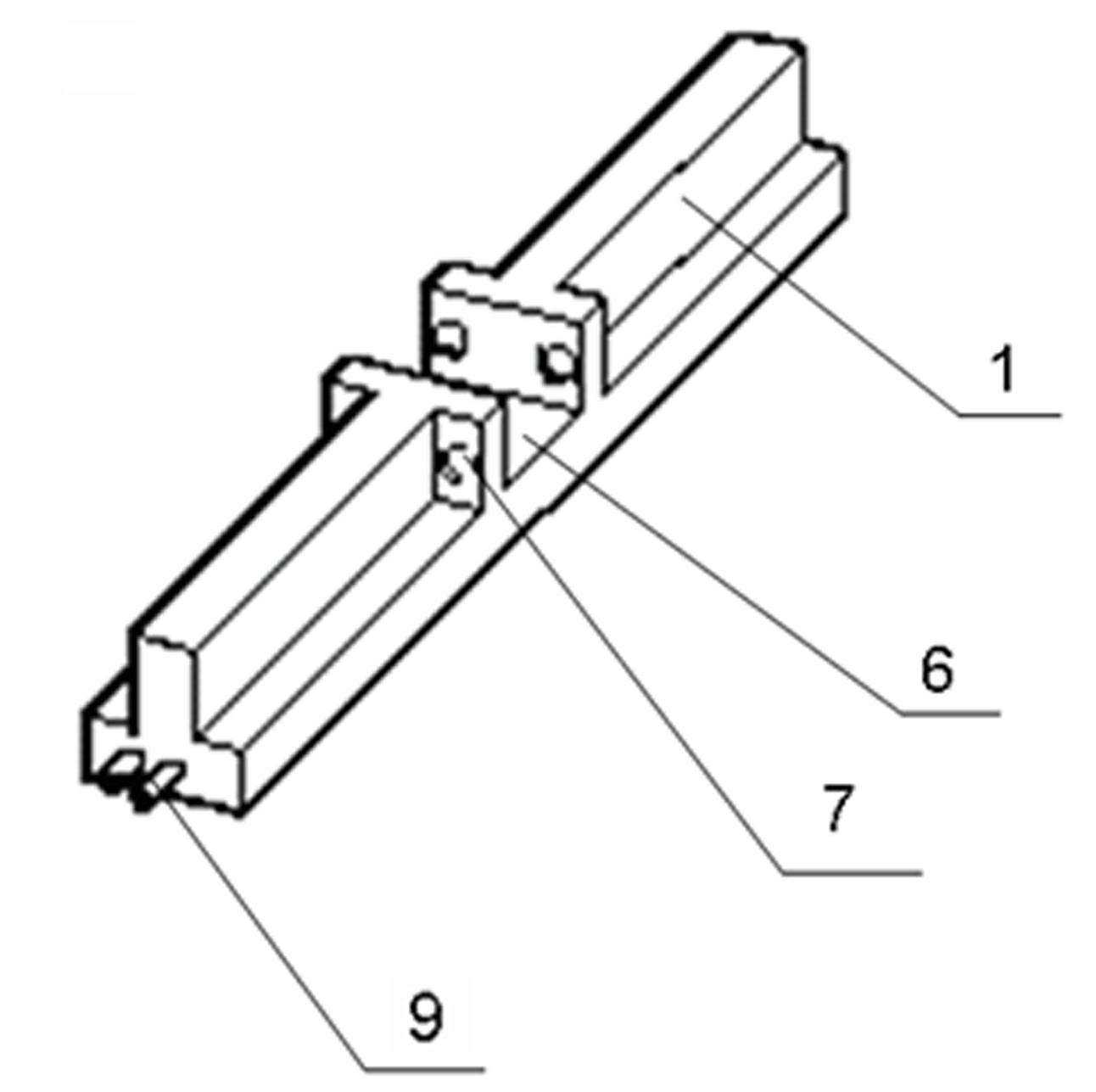

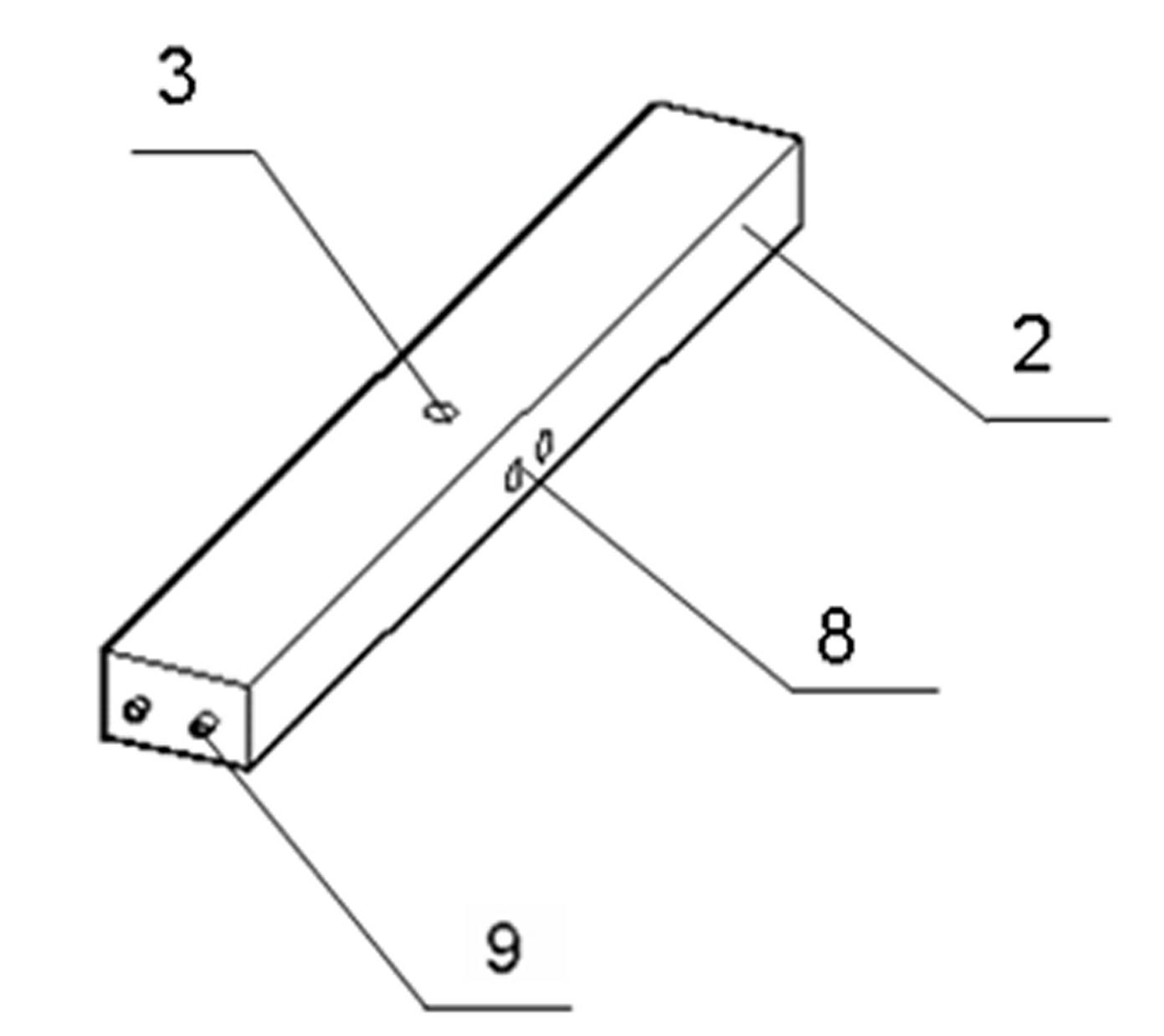

[0022] like Figure 1 to Figure 3 As shown, the assembled anchor (cable) frame provided by the present invention includes a cross-shaped lattice structure. The cross-shaped lattice structure is composed of a split vertical rib 1 and a beam 2. The middle part of the vertical rib 1 is provided with a The assembly groove 6 of the crossbeam 2 is placed in the assembly groove 6 of the vertical rib 1 across the middle, and the assembly groove reserved hole 7 of the vertical rib 1 corresponds to the reserved hole 8 in the middle of the crossbeam 2, which is convenient for bolt connection. When assembling on the slope construction site, if the vertical rib 1 and the beam 2 are prefabricated with concrete, the middle connection between the vertical rib 1 and the beam 2 is bonded with a high-strength concrete adhesive or high-stre...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com