Method for constructing foundation slab embedded with concrete supports

A foundation floor and construction method technology, which is applied in the direction of foundation structure engineering, excavation, artificial island, etc., can solve the problems of too long cantilever end at the lower part of the enclosure wall, unfavorable foundation pit deformation control, and slow construction speed, etc. The effects of foundation pit deformation control, avoidance of demolition and slag removal operations, and acceleration of construction speed

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment

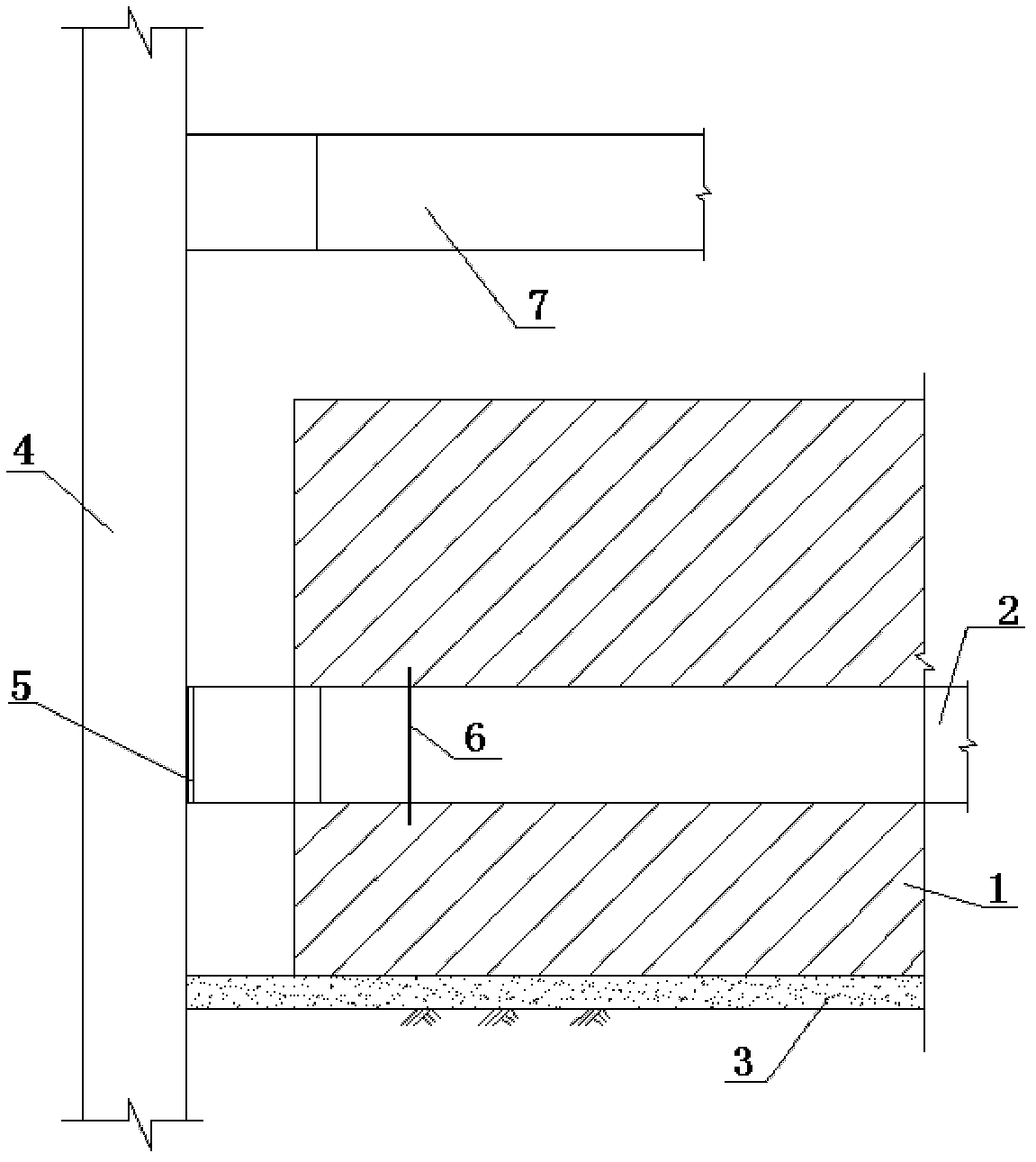

[0026] A specific embodiment, such as the construction of the foundation slab of a shipping plaza, due to the ultra-thick foundation slab, the thickness of the main building area slab is 5.0m, the continuous pouring volume of concrete is large, and the bottom support, that is, the fourth concrete support is located at the elevation of the slab Inside. If the conventional construction method is adopted, the cushion layer is poured first, then the fourth support is removed, and the bottom plate is finally poured. Then the unsupported cantilever end of the lower part of the retaining wall is 6.35m long, which is disadvantageous to the deformation control of the foundation pit and the construction speed is slow.

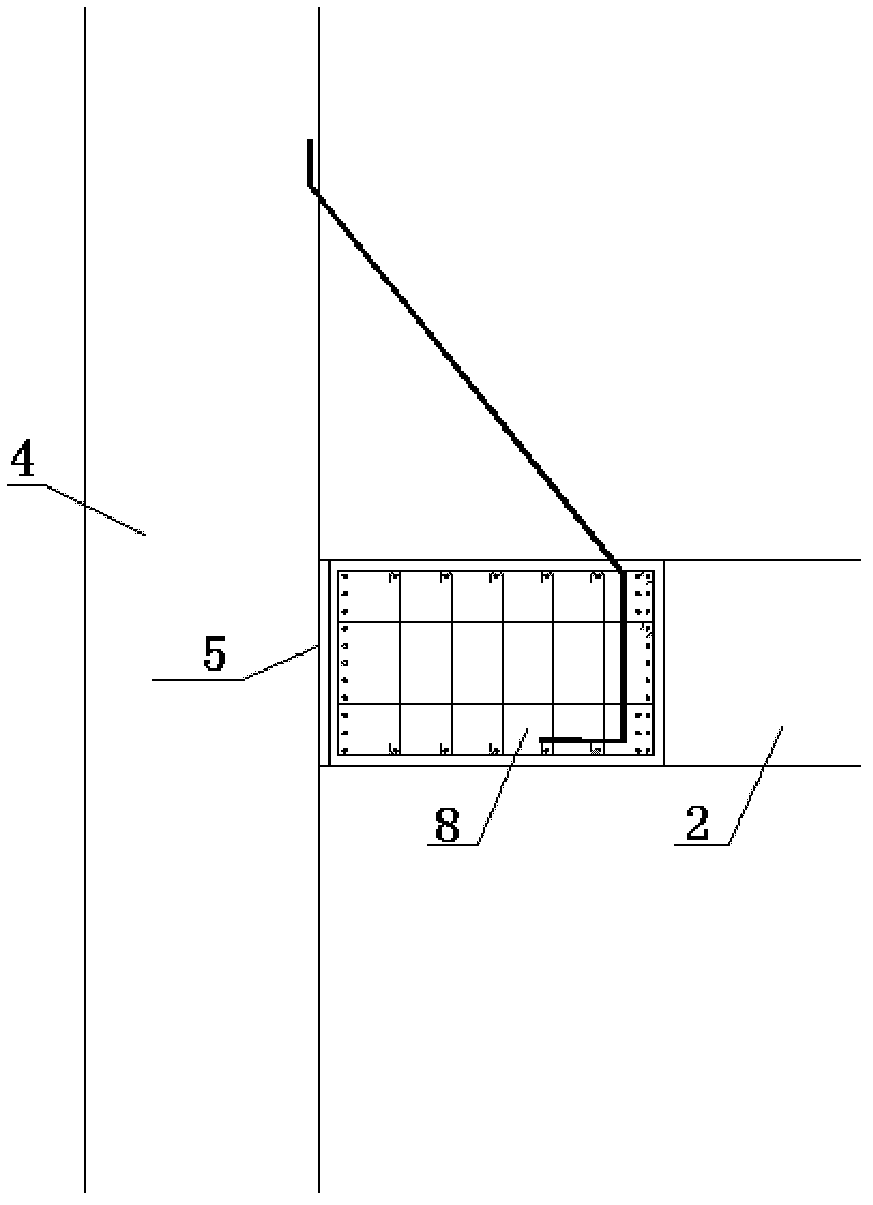

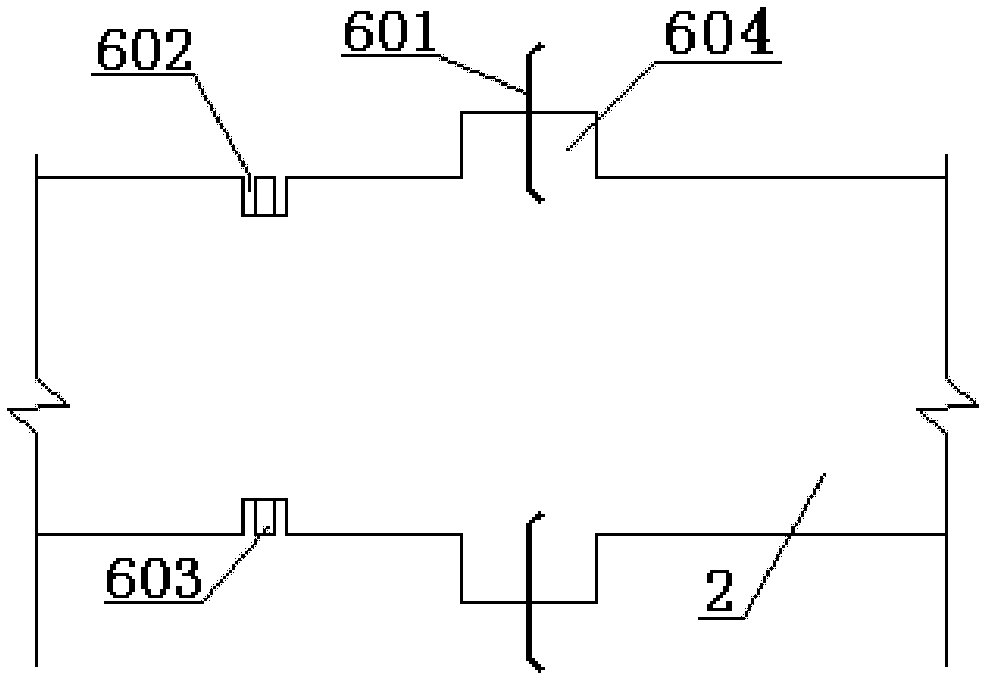

[0027] Such as Figure 1~4 As shown, the steps of the construction method of the concrete support embedded foundation base plate of the present invention are as follows:

[0028] (1) Dig the soil to the fourth support surface 2, tie the support steel bars, and pre-embed the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com