Easily detachable water turbine maintenance platform

A technology for repairing platforms and water turbines, applied in industrial buildings, etc., can solve problems such as increasing the difficulty of design and manufacturing, complex concrete pouring surface, sealing reliability, etc., to achieve compact structure, save space, and reduce damage to flow channels Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

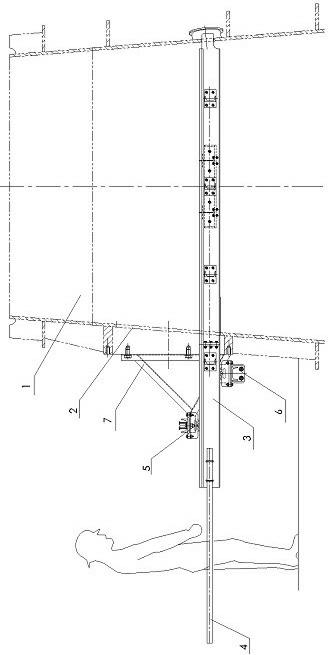

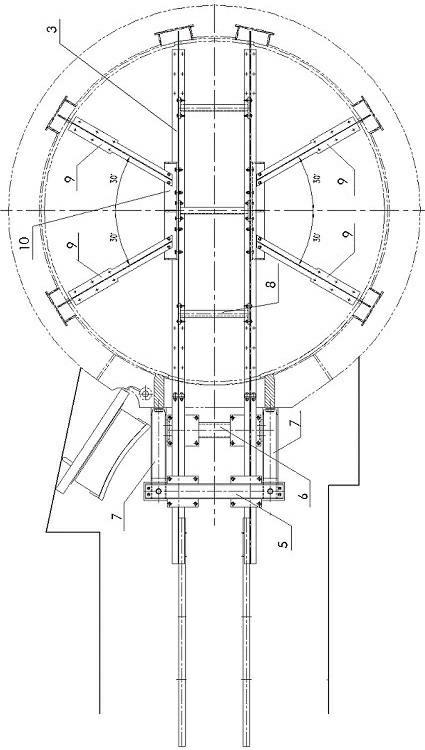

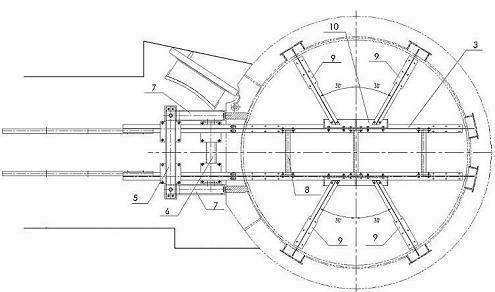

[0020] Specific embodiments of the present invention, such as figure 1 with figure 2 As shown, an easy-to-assemble and disassemble hydraulic turbine maintenance platform uses the existing screw holes on both sides of the draft tube 1 and the access door 2 to fix two triangular brackets 7 respectively, and install between the brackets 7 on both sides There are upper beams 5 and lower beams 6, forming a detachable and firm frame structure. The horizontal distance between the lower cross beam 6 and the entrance door 2 is smaller than the horizontal distance between the upper cross beam 5 and the entrance door 2, and rollers are arranged on opposite sides of the upper cross beam and the lower cross beam as the horizontal movement track of the main beam 3 . In addition, a height adjustment device is installed between the upper cross beam 5 and the bracket 7, which is realized by jacking bolts on both sides to meet the installation conditions on site. The adjustable way can be adju...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com