Torque amplifier for jumbolter

A technology of torque amplifier and bolt drilling rig, which is applied in the installation of bolts, earth-moving drilling, mechanical equipment, etc. The effect of improving labor efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

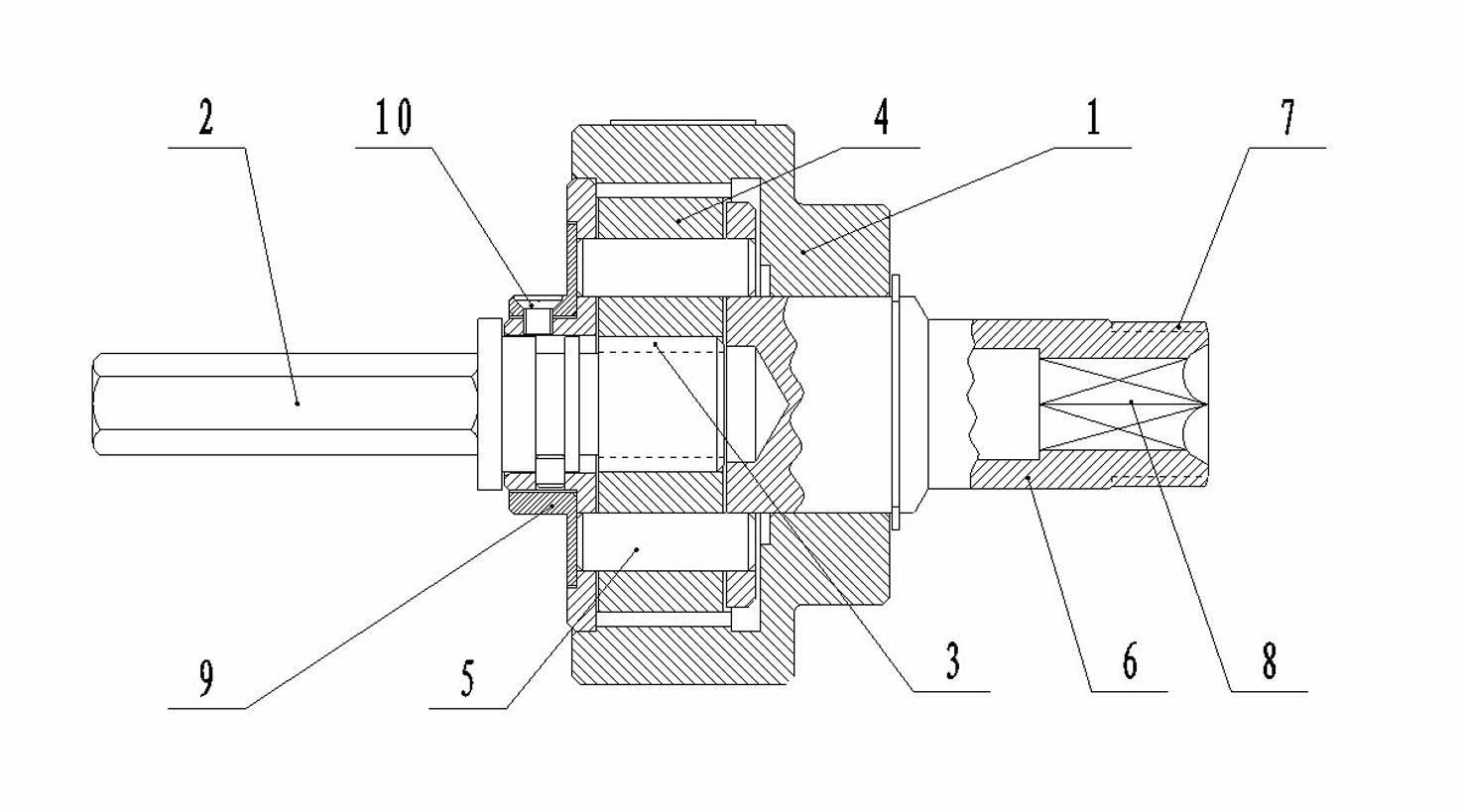

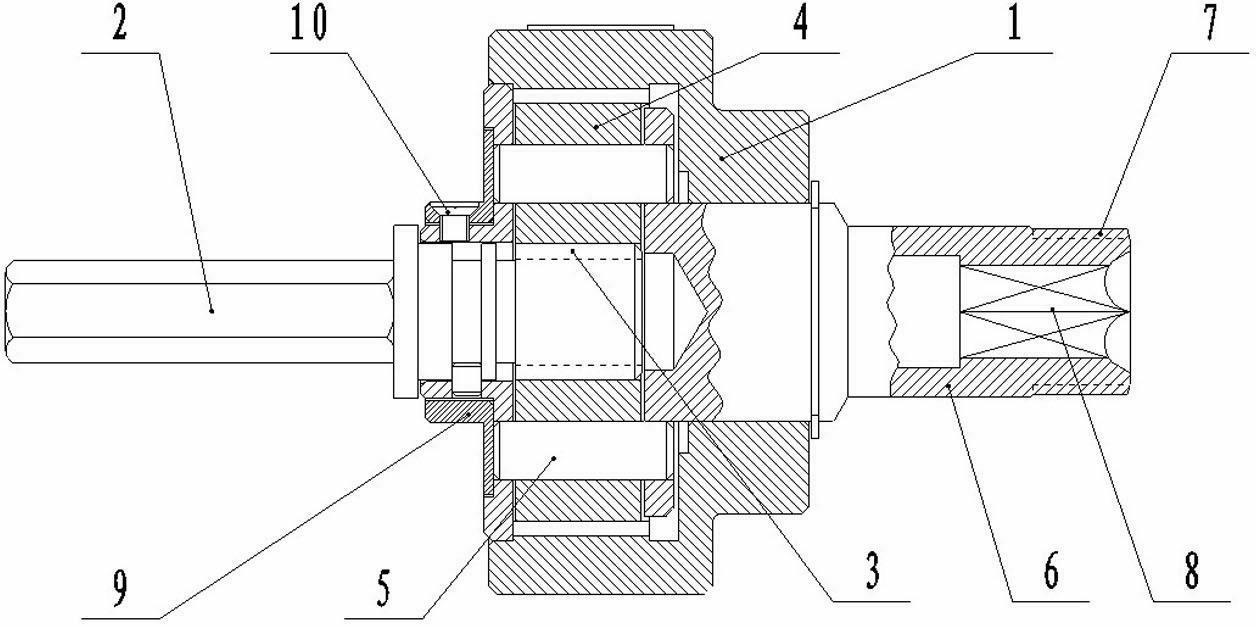

[0010] The torque amplifier of the rock bolter includes a stepped casing 1 whose diameter on the right side is smaller than that on the left side. The inner wall on the left side of the casing 1 is provided with a transmission ring gear. The left side of the casing 1 is provided with an input shaft 2 on which a The driving gear 3 is located in the sleeve 1. There are several planetary gears 4 meshing with the driving gear 3 and the transmission ring gear. The axes of the planetary gears 4 are all pierced with shaft pins 5. An output shaft 6 is fixed at the center of the shaft. The outside of the side wall of the output shaft 6 is provided with a trapezoidal thread 7; the outer end of the output shaft 6 is provided with an inner hexagonal hole 8. In the specific implementation process, the driving gear 3, the planetary gear 4 and the transmission ring gear are all selected with relatively large and reasonable modulus, thereby increasing the strength of the gears, and making the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com