Hydraulic-control limited rotational speed difference differential

A differential, limited technology, applied in the direction of differential transmission, belt/chain/gear, mechanical equipment, etc., can solve the problems of differential speed, differential force, large torque, etc., to prevent the differential speed from being too large, Low production cost and effect of differential force function

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

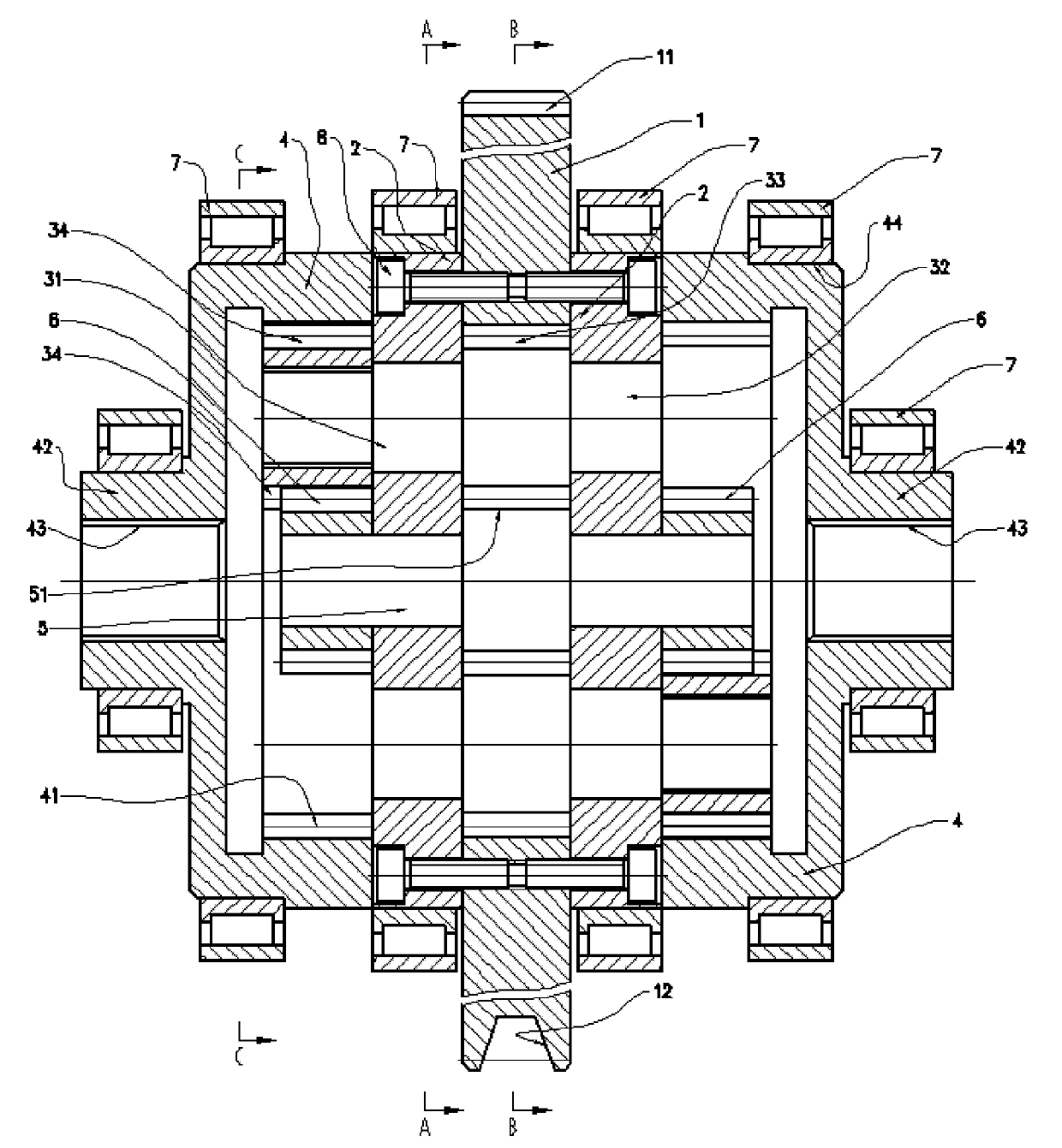

[0016] figure 1 In the figure, the upper part of the outer circle of the power input wheel is the tooth of the cylindrical gear, and the lower part is the groove of the pulley; the inner hole of the power input wheel in the figure is a round hole, and the closed shaft is an independent cylindrical shape .

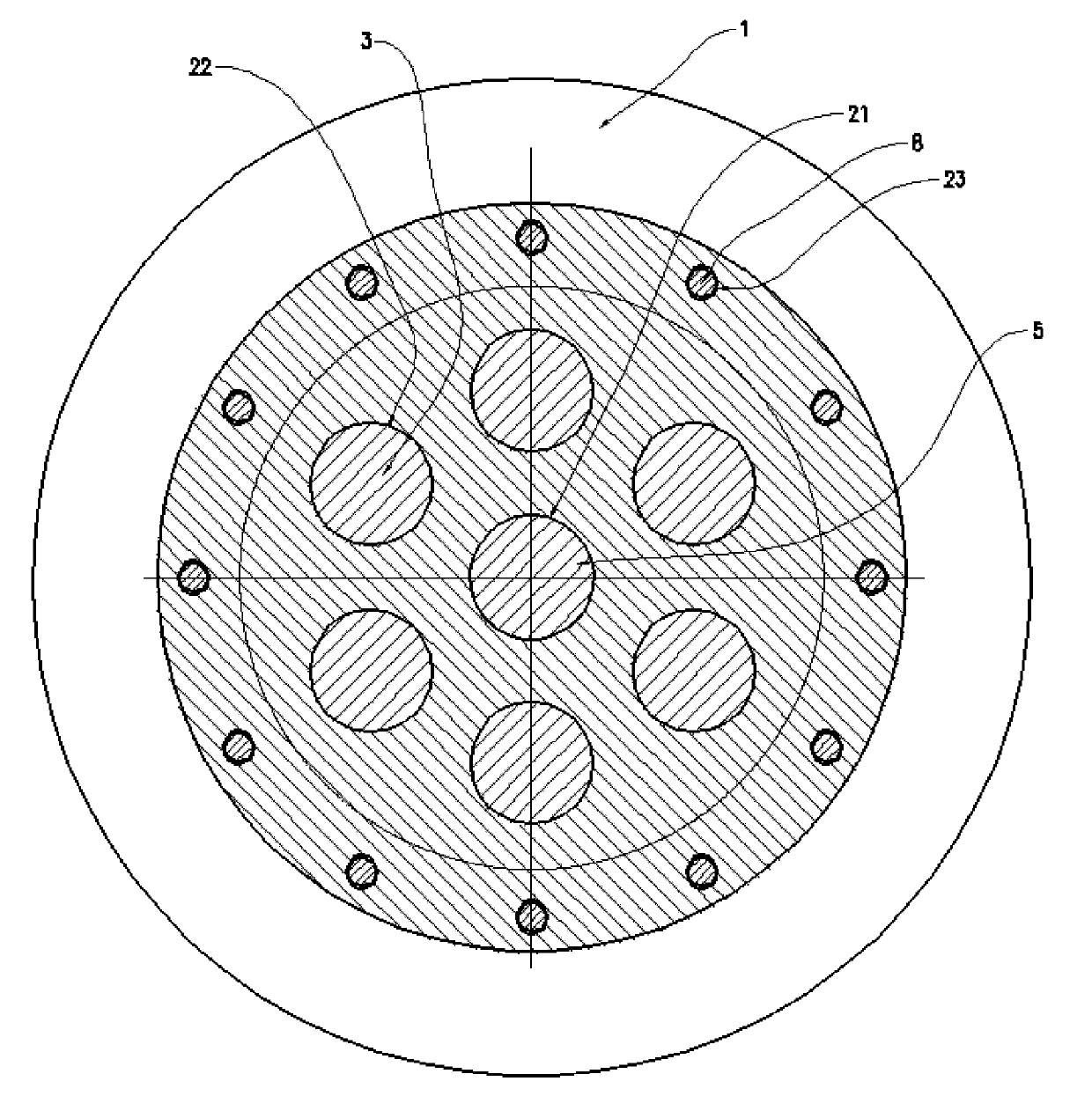

[0017] Such as figure 1 As shown, the power input wheel 1, two disc-shaped cover plates 2, three to six pairs of double planetary gear assemblies 3, two output wheels 4 composed of internally toothed cylindrical gears, a central closed shaft 5 and a central gear 6 and The bearing 7, the connecting screw 8 and the shell that are used to support the rotation of each part are formed.

[0018] The power input wheel 1 is ring-shaped, with gear teeth 11 or wheel grooves 12 on the outer edge to realize power input, and the inner hole is a round hole 14 or an outer crescent-shaped hole 15; Fix the disc-shaped cover plate 2 with the threaded hole 23 on the cover plate 2. There is...

Embodiment 2

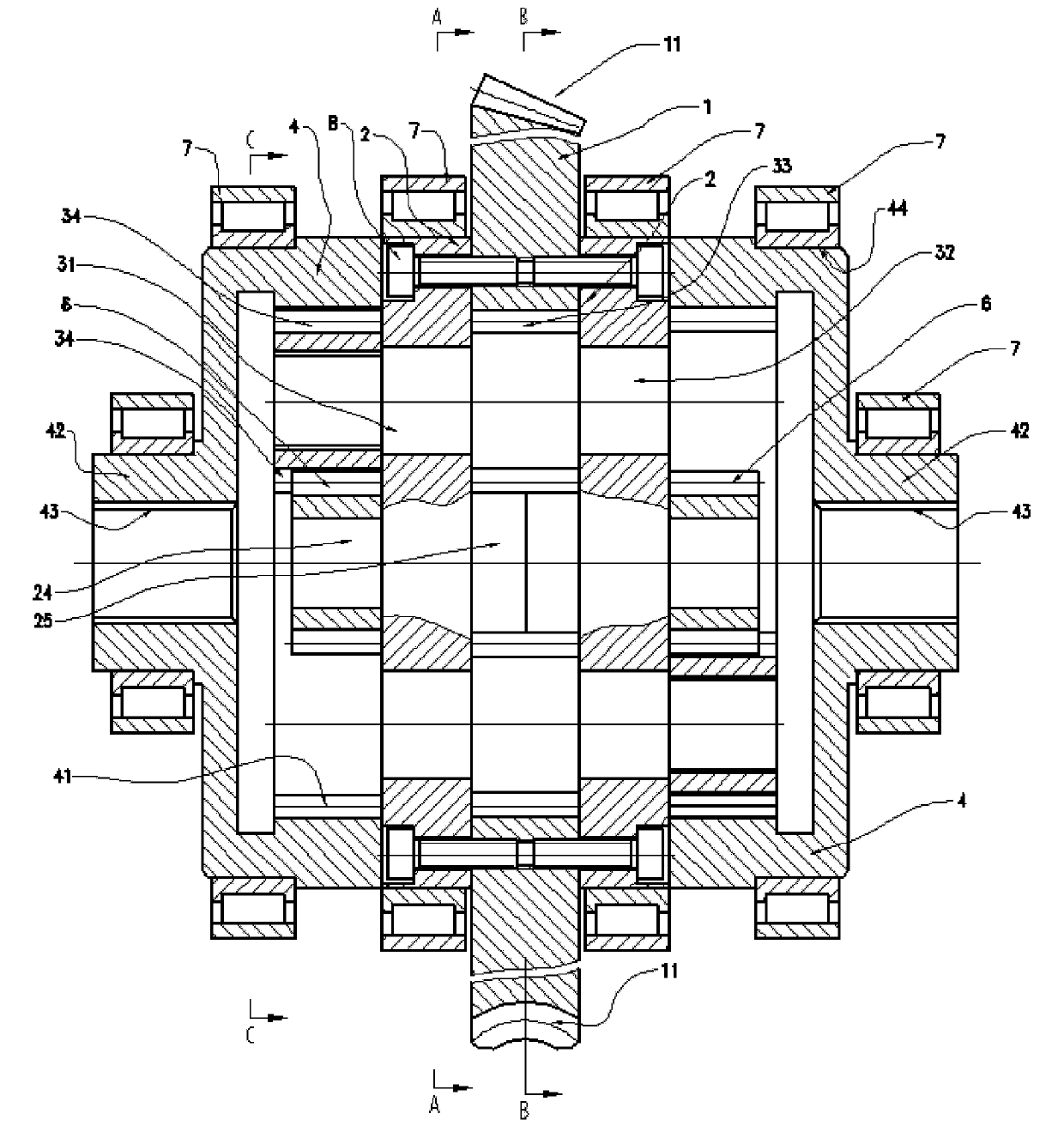

[0020] figure 2 , the upper part of the outer edge of the power input wheel is the tooth of the bevel gear, and the lower part is the tooth of the worm wheel; and for figure 1 The structure of the cover plate has been changed: the inner and outer sides of the central part of the disc-shaped cover plate are made into raised shaft sections to complete figure 1 Central closed shaft function, the center gear is installed on the central shaft of the cover plate protruding outside the cover plate, and the protruding shaft section inside the cover plate is a crescent-shaped closed shaft inside the cover plate.

[0021] Such as figure 2 As shown, this embodiment and figure 1 The difference is: the power input wheel 1 is ring-shaped, and its outer edge can be the upper half of the gear tooth 11 figure of the bevel gear, or the lower half of the gear tooth figure of the worm gear, and the power input is realized by the power input wheel 1. The cylindrical surface of the inner hole ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com