Silicon micro-resonant mode pressure sensor based on differential motion structure with coupling beam

A pressure sensor and coupling beam technology, applied in the field of sensors, can solve problems such as complex manufacturing process and difficulty in external circuit detection, and achieve the effects of improving sensitivity, reducing detection difficulty, and high quality factor

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

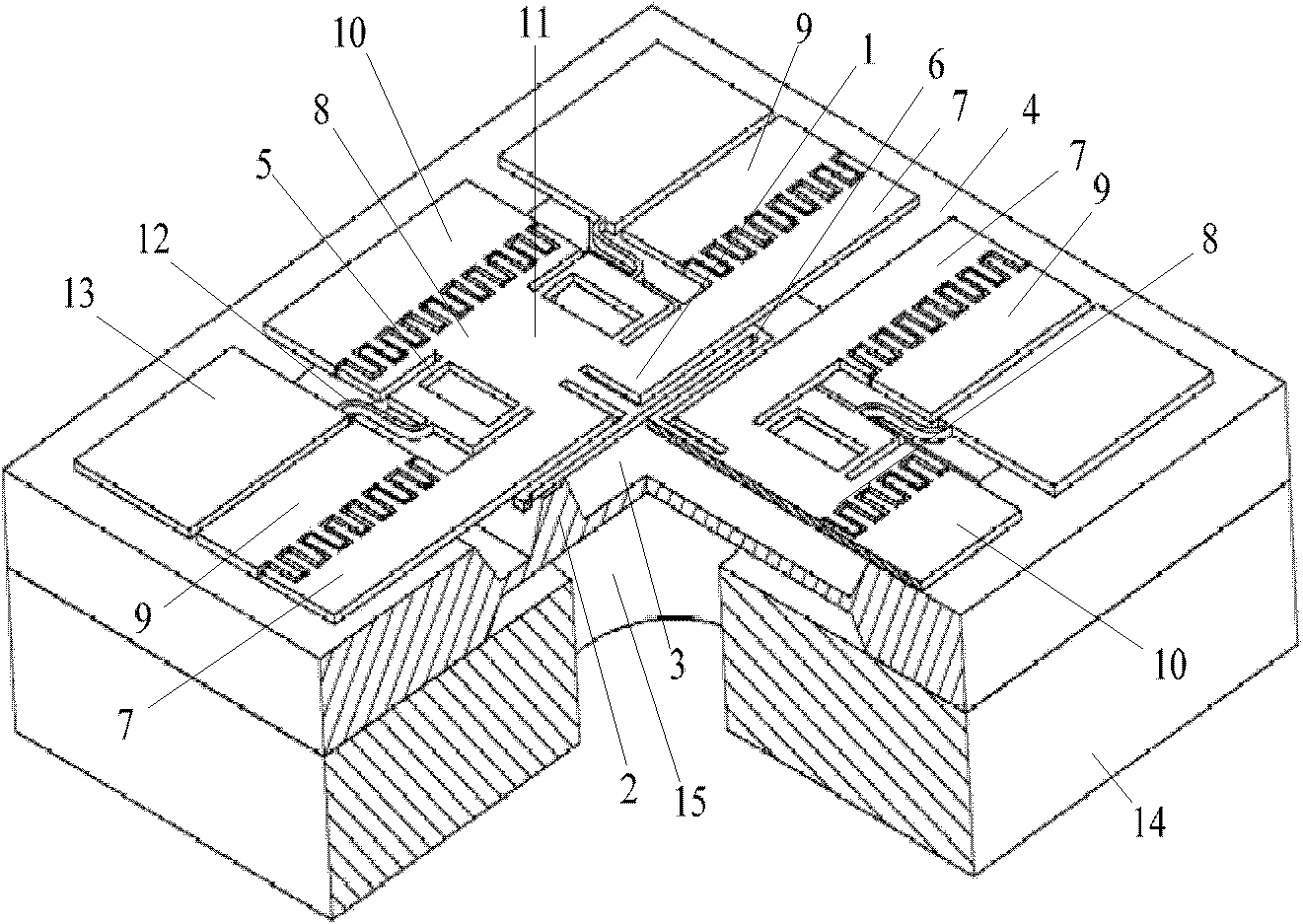

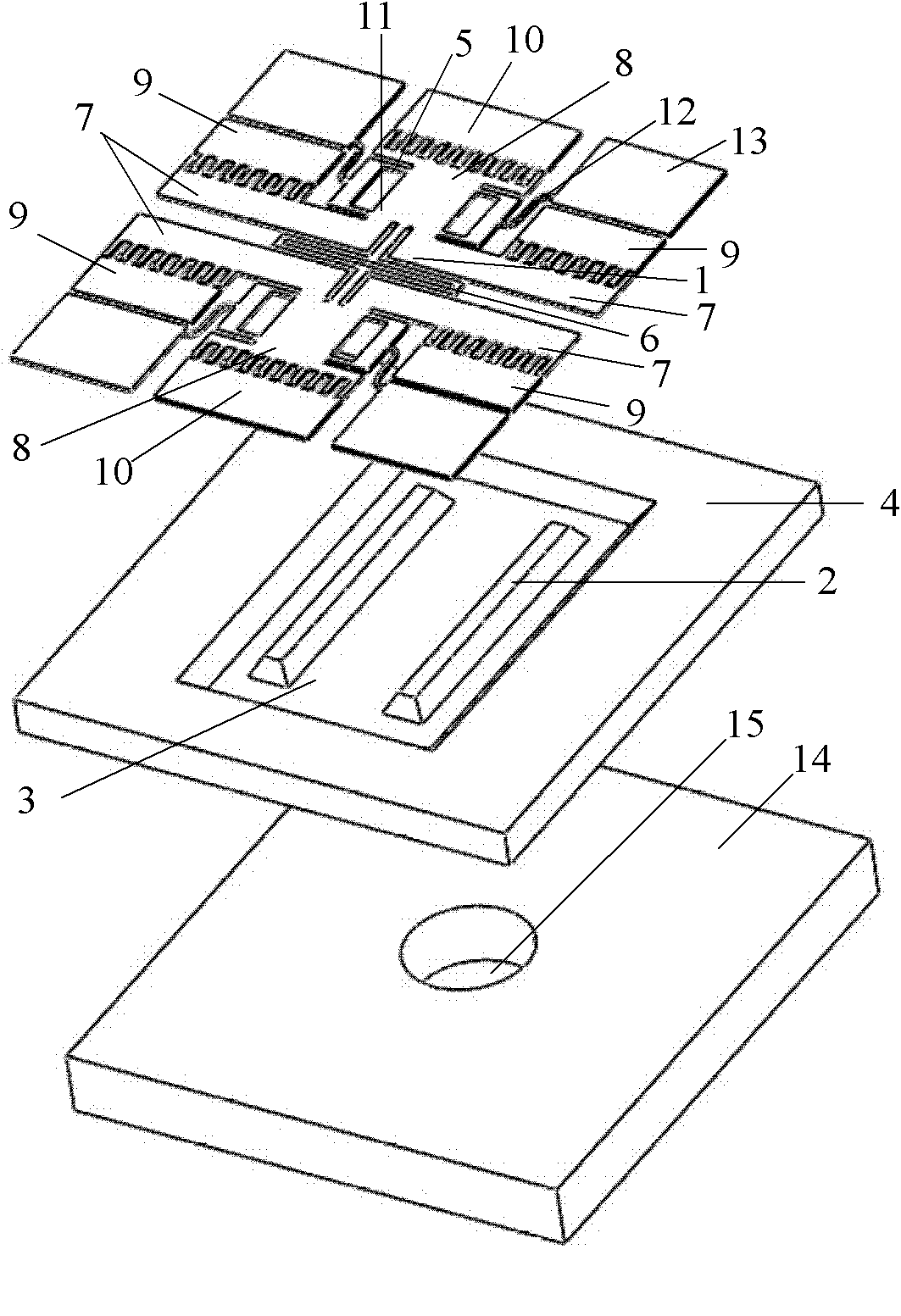

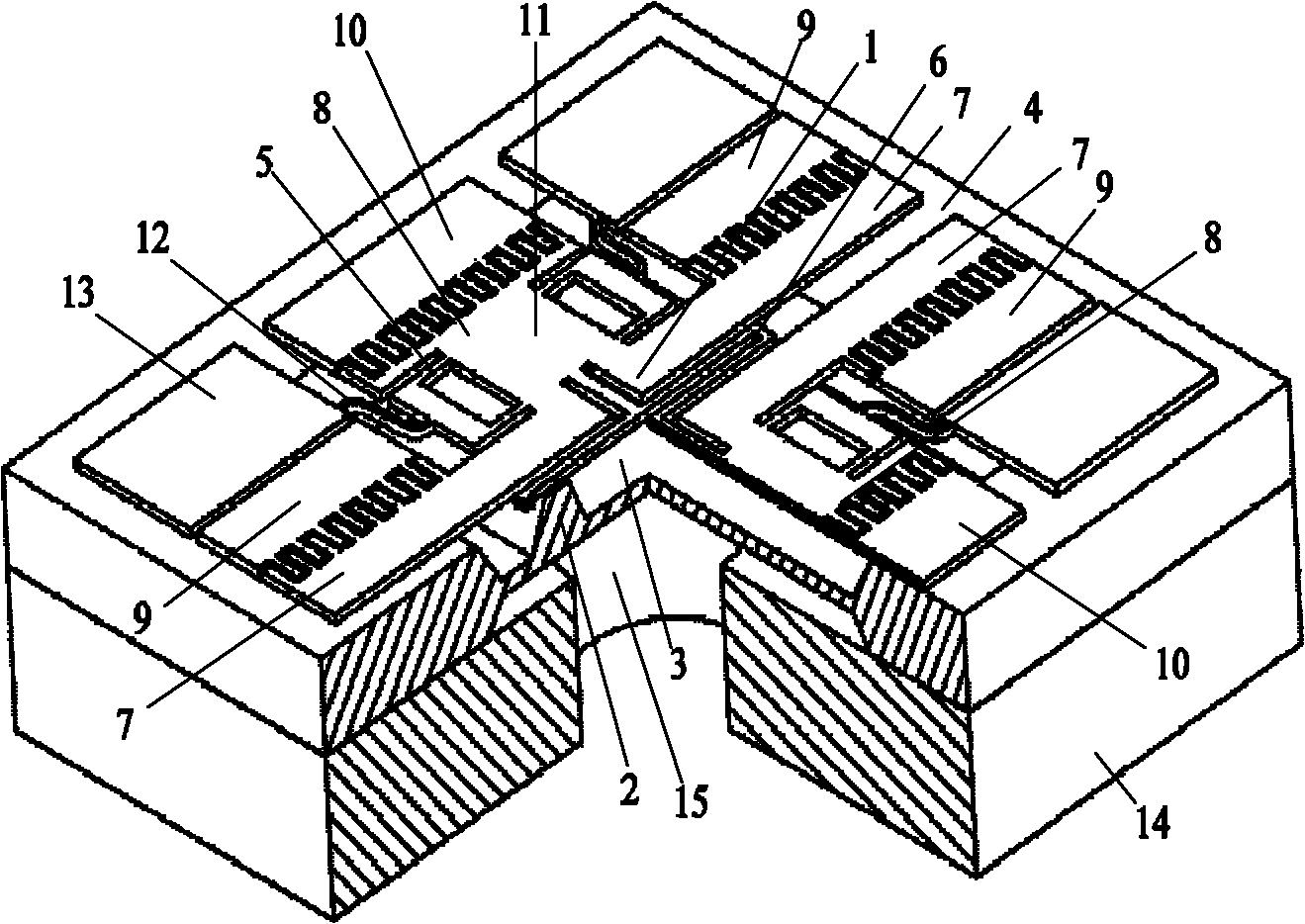

[0015] see figure 1 and 2 , the embodiment of the present invention is provided with a resonator 1, two rectangular silicon islands 2, a rectangular pressure-sensitive diaphragm 3, a silicon frame 4 and a lower glass 14; the resonator 1 is provided with 8 supporting beams 5 and 1 coupling beam 6. 4 movable comb-tooth excitation electrodes 7, 2 movable comb-tooth detection electrodes 8, 4 fixed comb-tooth excitation electrodes 9, 2 fixed comb-tooth detection electrodes 10 and 2 vibrating masses 11, the rectangular The pressure-sensitive diaphragm 3 is fixed inside the silicon frame 4, and the two rectangular silicon islands 2 are set at the position where the rectangular pressure-sensitive diaphragm 3 is subjected to the largest force deflection angle, and the two rectangular silicon islands 2 resonate through eight support beams 5 The son 1 is suspended on the surface of the rectangular pressure-sensitive diaphragm 3, and the eight support beams 5 are connected to the two rec...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com