Composite fault diagnosis method for diesel engine and diagnosis system

A technology of composite faults and diagnostic methods, applied in the direction of internal combustion engine testing, etc., can solve problems such as unsatisfactory fault detection accuracy, single detection means, and long detection cycle

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

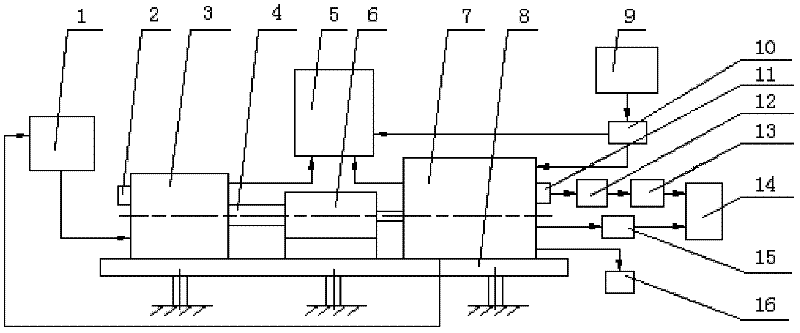

[0038] by figure 1 As shown, the diesel engine test platform for the diesel engine compound fault diagnosis method includes water tank 1, pressure sensor 2, water vortex dynamometer 3, coupling 4, dynamometer system 5, gearbox 6, diesel engine 7, and bench 8. , Fuel tank 9, fuel consumption meter 10, vibration acceleration sensor 11, data acquisition card 12, vibration analyzer 13, computer 14, exhaust gas analyzer 15, spectrum analyzer 16; the output shaft of diesel engine 7 is connected to transmission 6, and transmission 6 passes The coupling 4 is connected with the water vortex dynamometer 3, and the water vortex dynamometer 3 transmits the load to the diesel engine 7;

[0039] The diesel engine 7 is connected to a data acquisition card 12, a vibration analyzer 13, and a computer 14 through a vibration acceleration sensor 11; the diesel engine 7 is also connected to an exhaust gas analyzer 15 and a spectrum analyzer 16 respectively, and the exhaust gas analyzer 15 is connecte...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com