Method for detecting defects of chain belts of zipper on basis of digital image processing

A digital image and zipper technology, which is applied in the field of zipper belt defect detection based on digital image processing, can solve problems such as not getting a good solution, the zipper belt is in its infancy, and the belt is incomplete.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

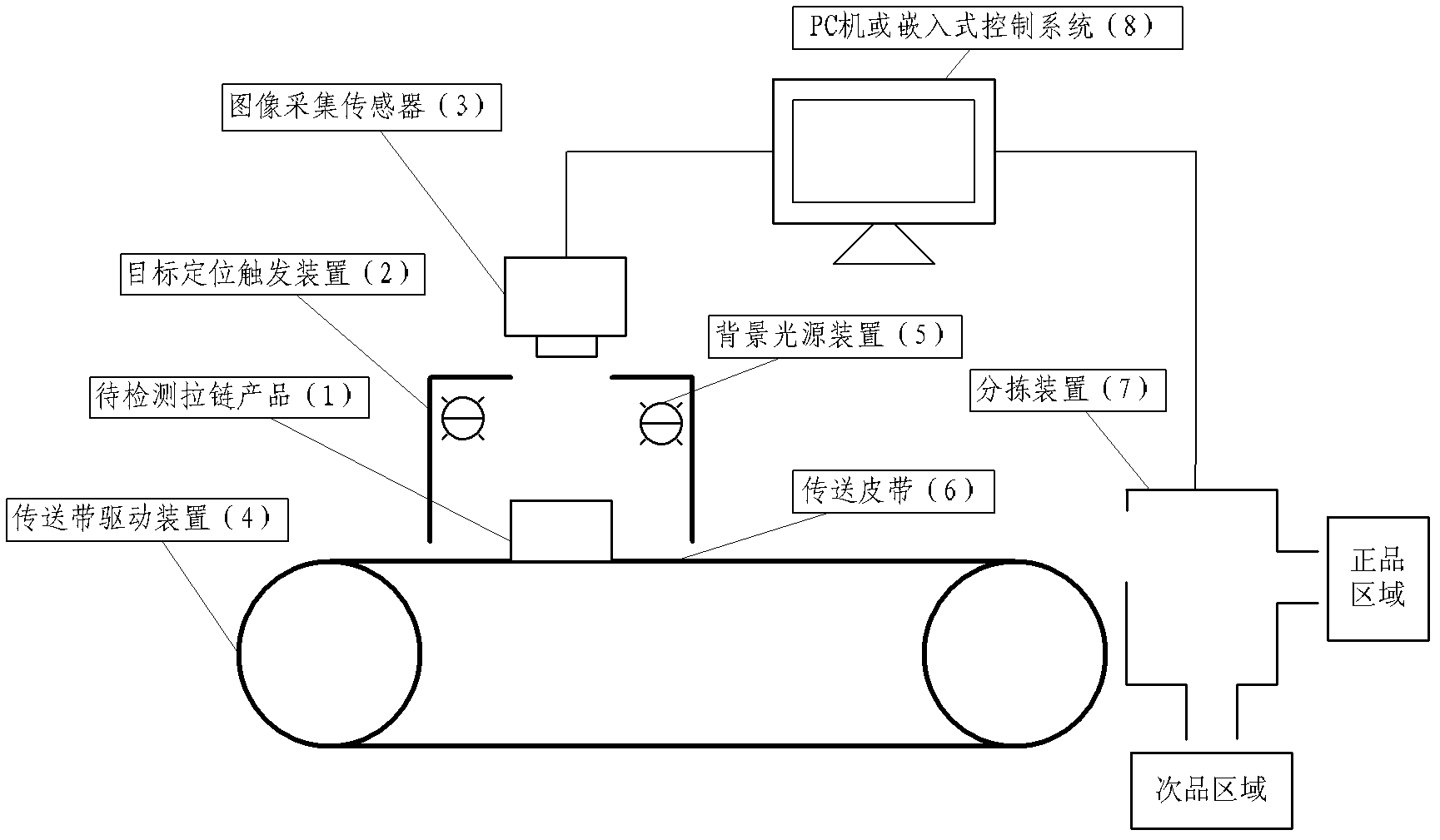

[0042] refer to figure 1 , a detection device based on a method for detecting defects of zipper chain belts based on digital image processing, comprising a target positioning trigger device 2, an image acquisition sensor 3, a conveyor belt drive device 4, a background light source device 5, a conveyor belt 6, and a sorting device 7 And PC machine or embedded control system 8 constitutes. Before the zipper product defect detection, the zipper production line has completed the processing of the zipper product 1 to be inspected, and the zipper is sent to the conveyor belt platform of the detection device. Driven by the conveyor belt driving device 4, the zipper product is conveyed by the conveyor belt 6 into the In the detection area, the target positioning trigger device 2 performs target positioning on the zipper product. If the zipper product has entered the central field of view of the image acquisition sensor, it triggers the LED bar light source of the background light sour...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com