A kind of ore-rock contact surface tracing method

A contact surface and ore-rock technology, which is applied in the field of ore-rock contact surface tracing and mining blasting caving ore-rock contact surface tracing, can solve the problems of ore loss and dilution, limited identification ability, and difficulty in identifying dyeing materials with the naked eye. The effect of controlling impoverishment indicators, improving accuracy and timeliness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

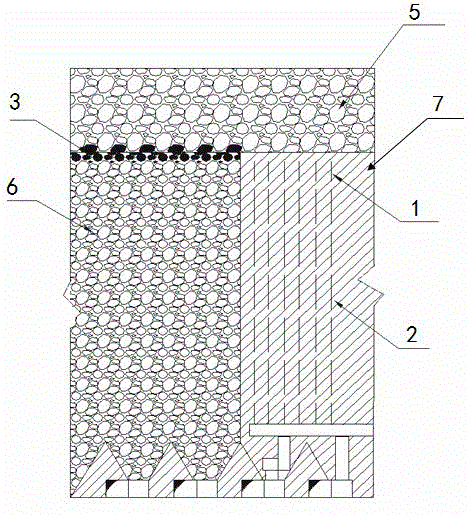

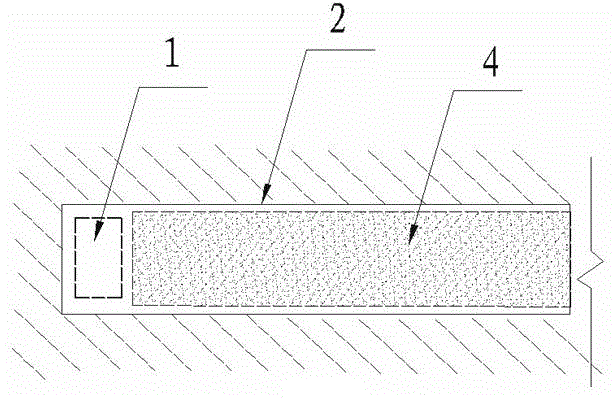

Embodiment 1

[0014] Fill 1Kg of ferromagnetic powder at the bottom of the blast hole that controls the boundary of the ore: Fe3O4 powder, particle size ≤ 8 microns, and the powder ferromagnetic material is filled in the form of a columnar charge suitable for the blast hole. When the explosive explodes, the ferromagnetic material is scattered on the broken ore or waste rock on the contact surface with the ore rock, and a ferromagnetic detection device is installed at the ore drawing port. As the ore is drawn, when the ferromagnetic detection device detects an abnormal signal, It is considered that the ore-rock contact surface has reached the ore-drawing mouth.

Embodiment 2

[0016] Fill 2Kg of ferromagnetic powder at the bottom of the blast hole that controls the boundary of the ore: ferric oxide powder, particle size ≤ 10 microns, and the powder ferromagnetic material is filled in the form of a columnar charge suitable for the blast hole. When the explosive explodes, the ferromagnetic material is scattered on the broken ore or waste rock on the ore-rock contact surface. A ferromagnetic detection device is installed on the working face of the ore. As the ore is drawn, when the ferromagnetic detection device detects an abnormal signal , it is considered that the ore-rock contact surface has reached the mining face.

Embodiment 3

[0018] Fill 350ml of water-based ferroferric oxide at the bottom of the blast hole controlling the boundary of the ore, and the filling of the water-based ferric oxide is in a closed container suitable for the blast hole. When the explosive explodes, the water-based ferroferric oxide is scattered on the broken ore or waste rock at the contact surface of the ore and rock, and a ferromagnetic detection device is installed at the ore drawing port. As the ore is drawn, when the ferromagnetic detection device detects an abnormality When the signal is signaled, it is considered that the ore-rock contact surface has reached the ore-drawing mouth.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com