SIM pasting film card packaging manufacturing method with lead bonding and screen printing moudling

A wire bonding and screen printing technology, applied in the manufacture of semiconductor/solid state devices, record carriers used in machines, instruments, etc. Stability, avoid high cost, improve the effect of stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

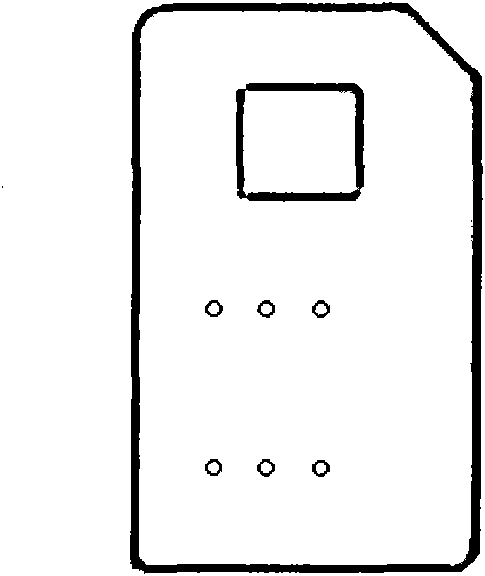

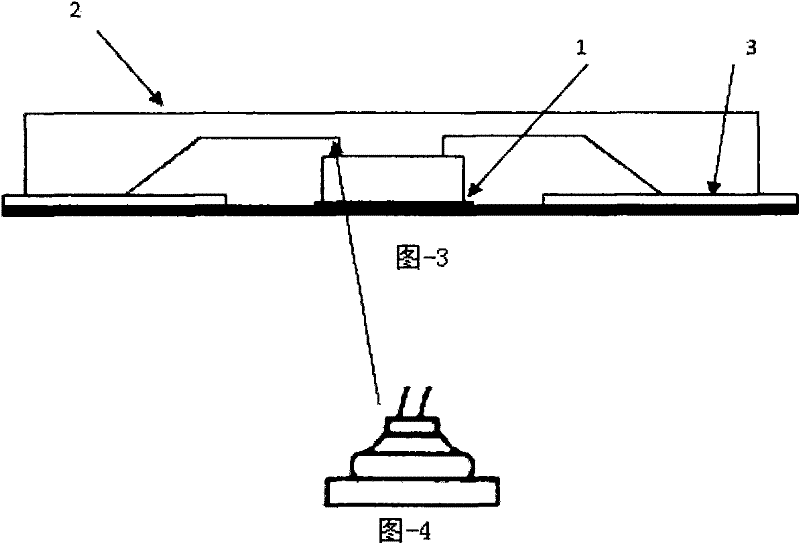

[0034] 1. Processing and production of a flexible circuit board for SIM film cards with metal bumps, the position of the metal bumps meets the requirements of the 7816 location area. On the side of the flexible circuit board with metal bumps, there are areas for mounting chips and pads using wire bonding. The pads pass through the lines of the flexible circuit board and are respectively connected to the metal points of the SIM film card and the SIM film card. The pins are connected, so that one side has a physical interface physically connected to a mobile phone terminal Universal Integrated Circuit Card (UICC), and the other side has a physical interface physically connected to a standard Universal Integrated Circuit Card (UICC).

[0035] 2. The flexible circuit board assembly of the SIM film card is designed as follows: a single splicing unit flexible circuit board substrate contains multiple SIM film card flexible circuit boards, and the entire substrate can also be composed...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com