Novel dovetail groove guide fixture

A dovetail-oriented and dovetail-slot technology, applied in semiconductor devices, sustainable manufacturing/processing, electrical components, etc., can solve the problems affecting the ingot loading efficiency, safety, slicing effect and service life, affecting the ingot loading efficiency and Safety and slicing effect, affecting the efficiency and safety of the ingot on the machine, to achieve the effect of improving efficiency and safety, slicing effect, improving operational safety, and improving the yield of slicing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

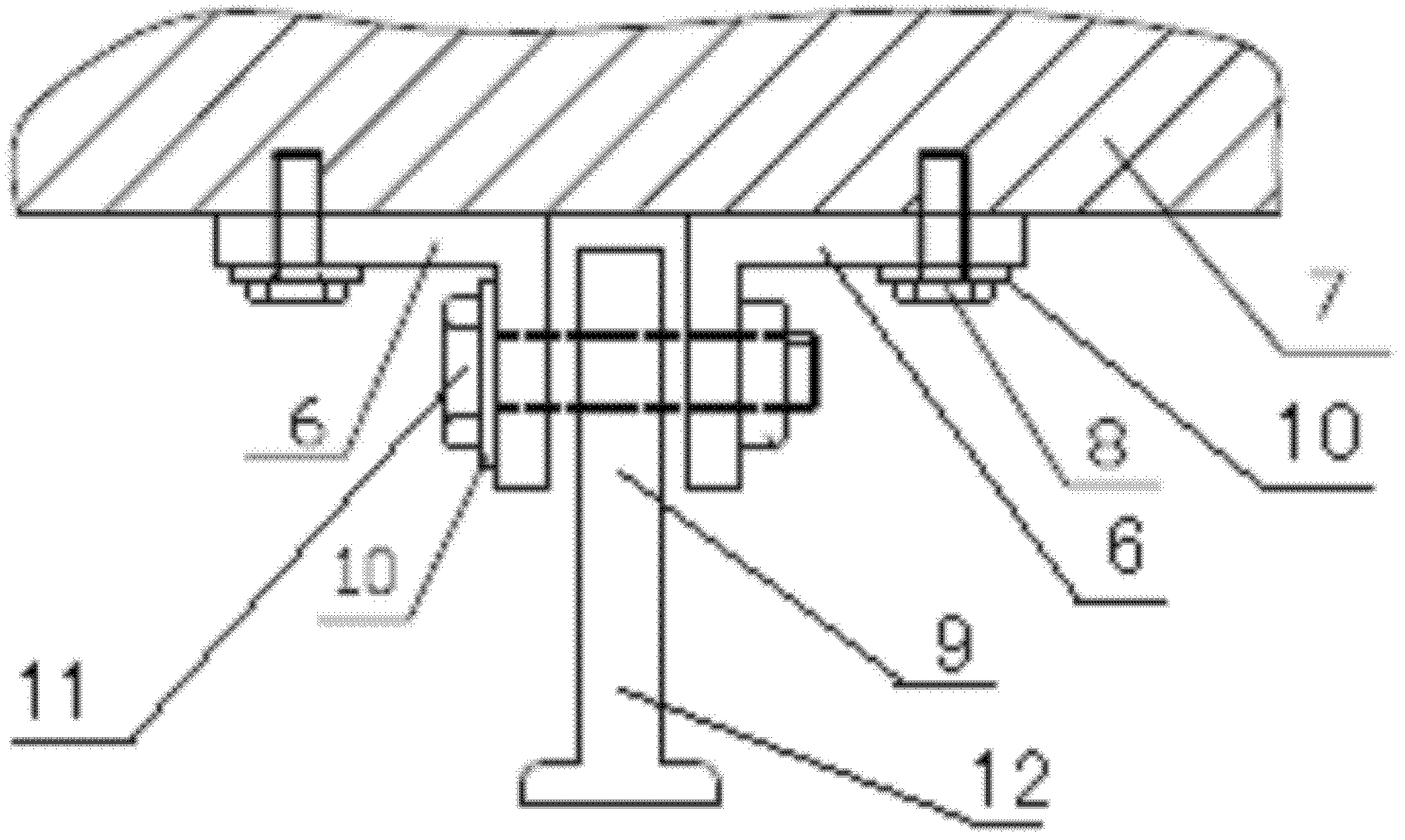

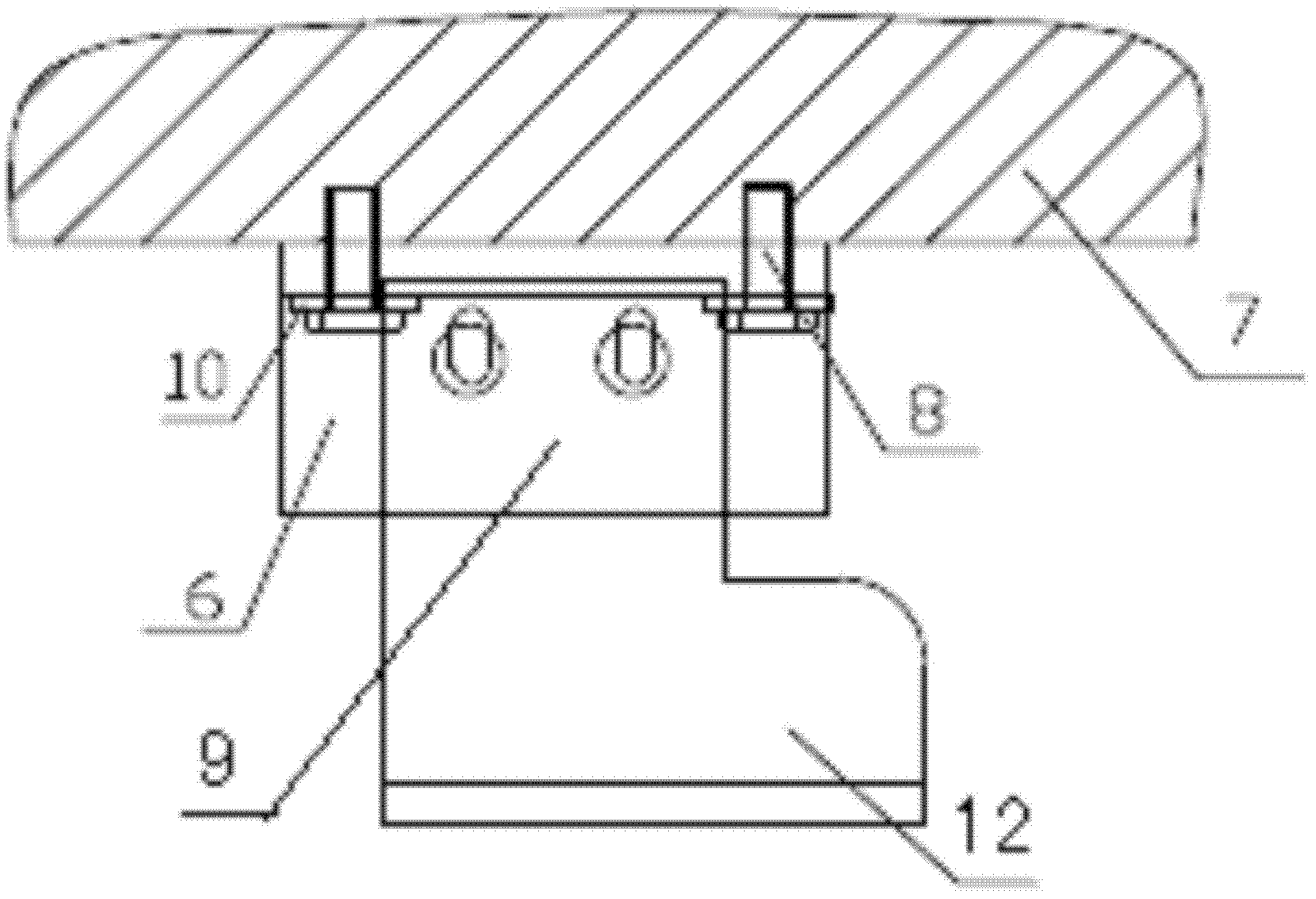

[0019] The present invention is described in detail below in conjunction with accompanying drawing

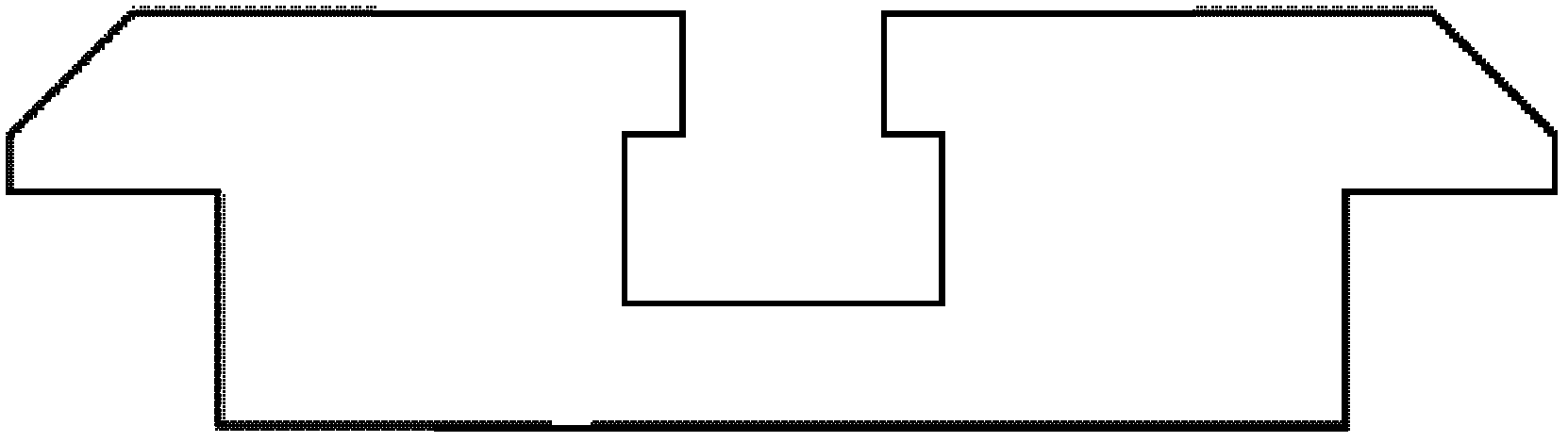

[0020] A new type of dovetail guide tooling, including: two fixed brackets 6 and a dovetail guide strip device, the fixed bracket 6 is in the shape of "L", and the two fixed brackets 6 are fixedly connected to the inner wall 7 of the equipment through the fixed bracket screws 8, respectively. The dovetail guide bar device comprises the inverted "T" shape guide platform 12 below the connecting plate 9 and the connecting plate 9, the connecting plate 9 is fixed in the middle of the two fixing brackets 6 by the connecting plate screw 11, and the inverted “T” below the connecting plate 9 and the connecting plate 9 "T" shape guide platform 12 is combined into a whole.

[0021] The thickness of the two fixing brackets 6 is 3mm-4mm, and the material is chrome.

[0022] Also includes gasket 10, gasket 10 is provided on the fixing bracket screw 8, gasket 10 is provided on the connectin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com