Modeling method and system for correcting and predicting arc extinguishing angle

A modeling method and arc extinguishing angle technology, applied to output power conversion devices, electrical components, circuit devices, etc., can solve problems such as inability to measure the arc extinguishing angle, unfavorable system stability, and poor results

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0051] Below in conjunction with accompanying drawing and embodiment the present invention will be further described:

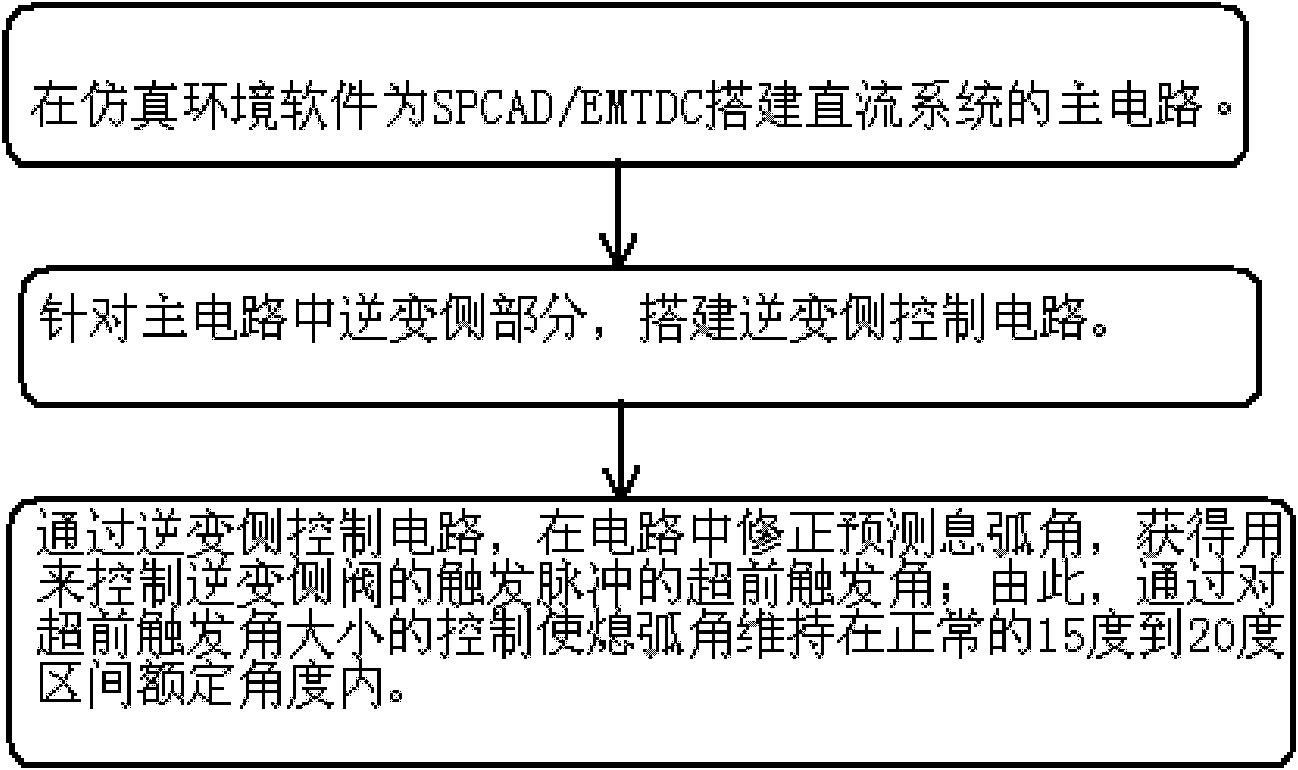

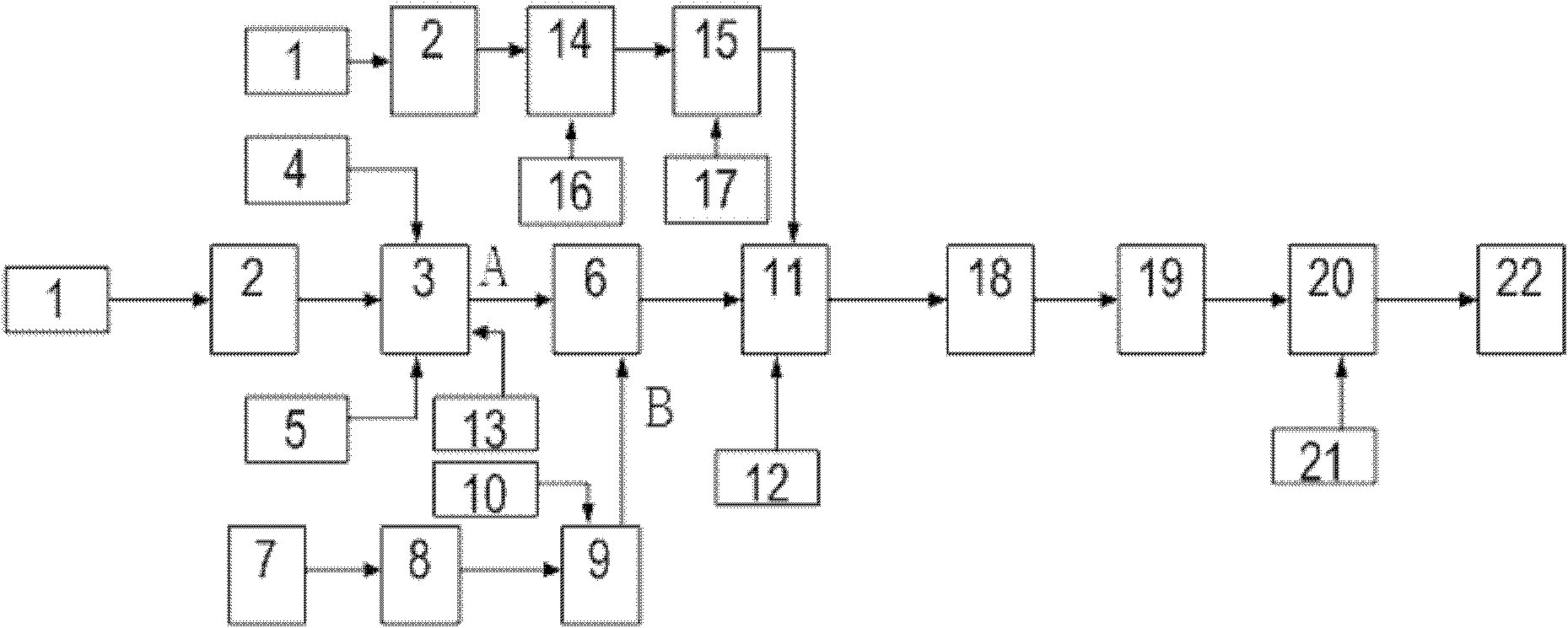

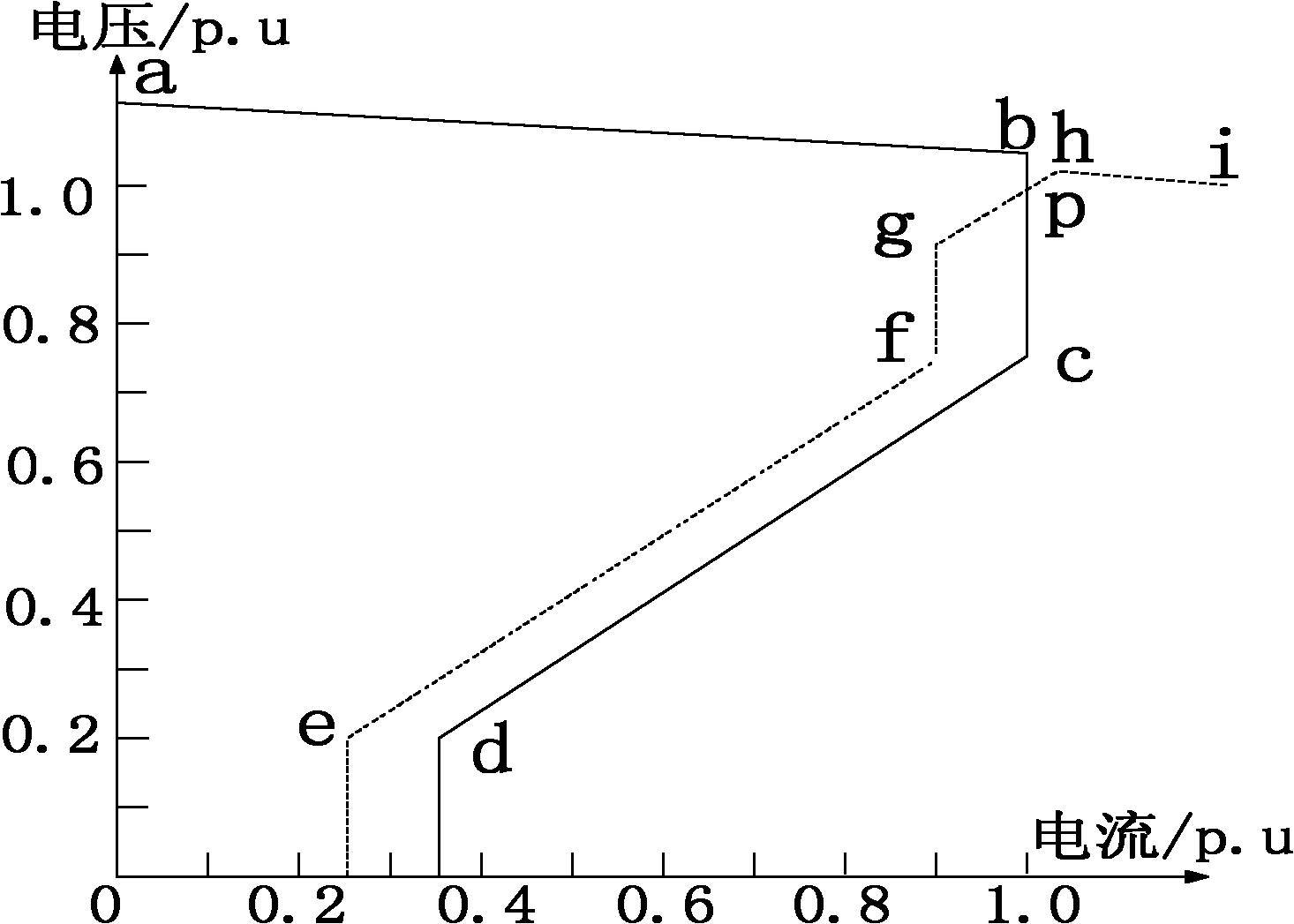

[0052] figure 1 , figure 2 Among them, a method and system for correcting and predicting the arc-extinguishing angle modeling are specifically implemented, and the specific steps it includes are as follows: 1) Build the main circuit of the DC system for PSCAD / EMTDC in the simulation environment software; the main circuit includes the inverter side 2) For the inverter side part in the main circuit, build the inverter side control circuit, and form the DC system circuit together with the main circuit described in step 1); 3) Correct the forecast information in the circuit through the inverter side control circuit The arc angle is used to obtain the leading firing angle of the firing pulse used to control the inverter side valve; thus, the arc extinguishing angle is maintained within the normal range of 15° to 20° by controlling the size of the leading firing ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com