Interplanting sowing machine

A seeding machine, sowing and ditching technology, which is applied to agricultural machinery and tools, shovels, plows, etc., can solve the problems of low working efficiency, not significantly improved working efficiency, and unsuitable for interplanting and sowing, so as to improve the integration of machinery The degree of modernization, the effect of improving work efficiency and reducing labor intensity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] The present invention will be described in further detail below in conjunction with the accompanying drawings and specific embodiments.

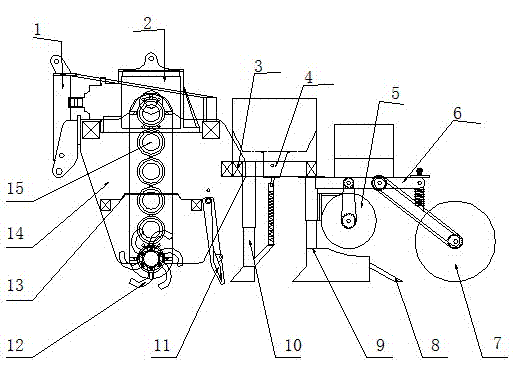

[0020] according to figure 1 , figure 2 The shown interplanting planter includes a rotary tiller frame 14, and the rotary tiller frame 14 is divided into three areas, including an operation area A placed at both axial ends for rotary tillage and an operation area A placed at both ends. A crop avoidance area B through which crops can pass between A, and a rotary tiller 12 is provided in each of the two operation areas A.

[0021] Preferably, the width of each operation area A is 80 cm to 100 cm, the width of the crop avoidance area B is 80 cm to 120 cm, and the height of the crop avoidance area B from the ground is 5 cm to 75 cm. This structural design can make the original crops on the ground pass through the crop avoidance area B without being damaged by machinery. On both sides of the crop avoidance area B is the operation area A...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap