Air channel system of pilot type control belt intelligent PEEP (positive end expiratory pressure) breathing machine

A technology for controlling belts and air circuits, which is applied in the field of medical electronics, can solve the problems of high requirements for air supply control solenoid valves, short service life, increased work of breathing, etc., achieve continuous adjustment of oxygen concentration, improve service life, and exhale smooth effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

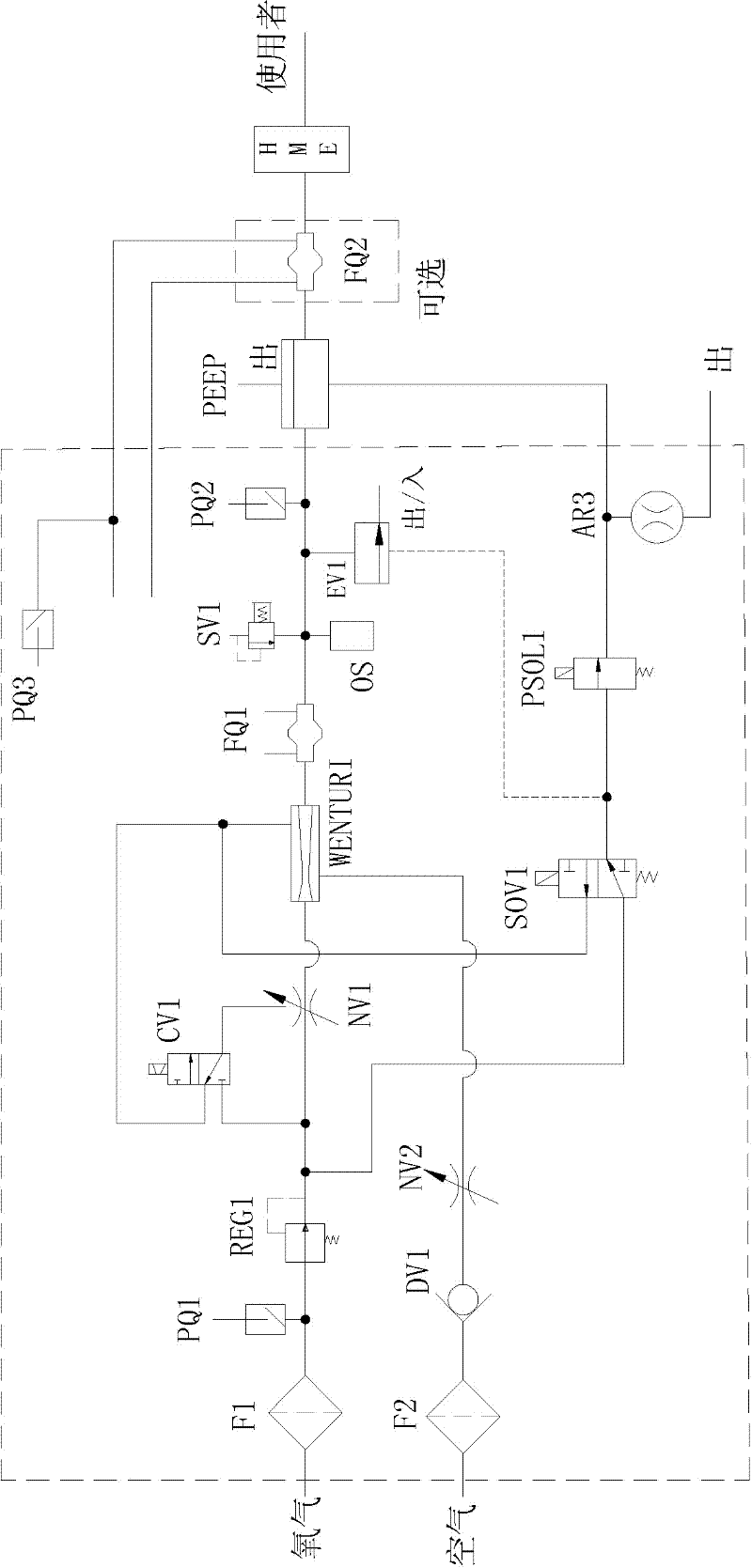

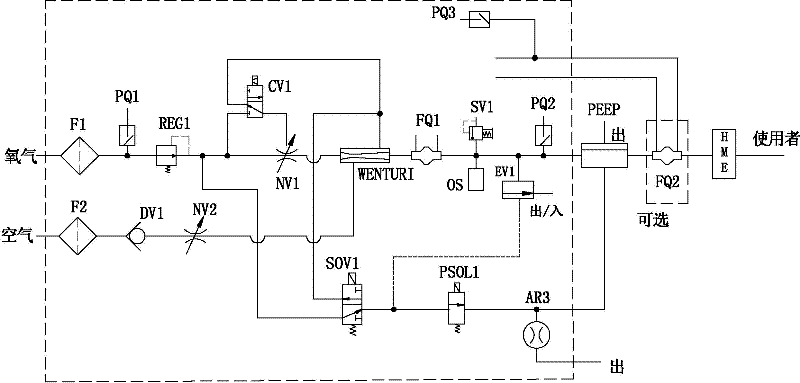

[0029] First, explain the key points of the gas path of the present invention:

[0030] (1) Peep controls the branch air circuit and the proportional solenoid valve PSOL1 and safety solenoid valve SOV1 in collusion on it. When the pressure is too high, the safety solenoid valve SOV1 is closed, so that the user can breathe freely and improve safety;

[0031] (2) Venturi device and auxiliary pipeline structure, which can inhale air from the bypass, realize the mixing of air and oxygen, and reduce the oxygen concentration;

[0032] (3) The oxygen flow regulating valve NV1 controlled by the gas supply control solenoid valve CV1 adopts a non-serial structure, and the internal diameter of the gas supply control solenoid valve CV1 can be very small.

[0033] Second, illustrate the structure of the gas circuit system of a specific embodiment of the present invention:

[0034] The Peep ventilator gas circuit system of the specific embodiment of the present invention and the sensor on ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com