Monolithic catalyst for coal mine low-concentration ventilation air methane (VAM) combustion and preparation method thereof

A monolithic catalyst, methane combustion technology, applied in the direction of chemical instruments and methods, physical/chemical process catalysts, metal/metal oxide/metal hydroxide catalysts, etc., can solve the problem of affecting the catalytic performance of precious metal components, and does not involve catalytic combustion , cumbersome preparation process, etc., to avoid sintering and crystallite growth, improve catalyst activity, and good stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

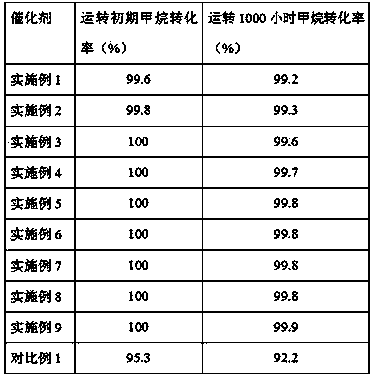

Examples

Embodiment 1

[0021] Weigh 23.2g γ-Al 2 o 3 Powder, add 300mL of deionized water, at a stirring speed of 300rpm, add 50mL of 1MHNO 3 solution, kept at 85°C for 4h, then naturally cooled to room temperature under stirring to obtain Al 2 o 3 Colloidal solution, 10.75gLa(NO 3 ) 3 .nH 2 O, 3.5gCe(NO 3 ) 3 .6H 2 O, 14.47gFe(NO 3 ) 3 .9H 2 Mix O, add 100mL of water to dissolve and mix with the above Al 2 o 3 The colloidal solution is mixed evenly. After keeping for 2h, the mixture was dried in air at 110°C for 3h, and calcined at 1200°C for 5h to obtain La 0.8 Ce 0.2 FeAl 11 o 19 .

[0022] Weigh 75g γ-Al 2 o 3 Powder, 25g La 0.8 Ce 0.2 FeAl 11 o 19Powder, mix evenly, add 4.0L of distilled water, and ball mill for 4 hours to form an aqueous slurry. Immerse the cordierite honeycomb ceramic body in the above water-containing slurry for 40 minutes, take it out, blow off the residual slurry in the hole with compressed air, dry it in the air at 110°C for 10 hours, and bake it ...

Embodiment 2

[0024] Weigh 23.2g γ-Al 2 o 3 Powder, add 300mL of deionized water, at a stirring speed of 300rpm, add 50mL of 1MHNO 3 solution, kept at 85°C for 4h, then naturally cooled to room temperature under stirring to obtain Al 2 o 3 Colloidal solution, 10.75gLa(NO 3 ) 3 .nH 2 O, 3.5gCe(NO 3 ) 3 .6H 2 O, 12.07gCo(NO 3 ) 3 .6H 2 Mix O, add 100mL of water to dissolve and mix with the above Al 2 o 3 The colloidal solution is mixed evenly. After keeping for 6h, the mixture was dried in air at 110°C for 5h, and calcined at 1200°C for 3h to obtain La 0.8 Ce 0.2 CoAl 11 o 19 .

[0025] Weigh 50g γ-Al 2 o 3 Powder, 50g La 0.8 Ce 0.2 CoAl 11 o 19 Powder, mix evenly, add 2.0L distilled water, and ball mill for 5 hours to form an aqueous slurry. Immerse the cordierite honeycomb ceramic body in the above water-containing slurry for 40 minutes, take it out, blow off the residual slurry in the hole with compressed air, dry it in the air at 120°C for 15 hours, and bake it in...

Embodiment 3

[0027] Weigh 23.2g γ-Al 2 o 3 Powder, add 300mL of deionized water, at a stirring speed of 300rpm, add 50mL of 1MHNO 3 solution, kept at 85°C for 4h, then naturally cooled to room temperature under stirring to obtain Al 2 o 3 Colloidal solution, 10.75gLa(NO 3 ) 3 .nH 2 O, 3.5gCe(NO 3 ) 3 .6H 2 O, 14.80g50%Mn(NO 3 ) 3 Mix 7.24g of the solution, add 100mL of water to dissolve and mix with the above Al 2 o 3 The colloidal solution is mixed evenly. After keeping for 2h, the mixture was dried in the air at 120°C for 7h, and calcined at 1200°C for 5h to obtain La 0.8 Ce 0.2 MnAl 11 o 19 .

[0028] Weigh 50g γ-Al 2 o 3 Powder, 50g La 0.8 Ce 0.2 MnAl 11 o 19 Powder, mix evenly, add 4.0L distilled water, grind carefully to form an aqueous slurry. Immerse the cordierite honeycomb ceramic body in the above water-containing slurry for 40 minutes, take it out, blow off the residual slurry in the hole with compressed air, dry it in the air at 120°C for 20 hours, and ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com