Process for improving content stability of soldering flux for solder, and device for vertically injecting soldering flux for solder

A technology of flux and tin wire, which is applied in the production field of cored solder wire, can solve the problems of flux waste, poor quality of tin wire, burns, etc., and achieve the effect of reducing the waste of solder and ensuring high-quality and stable product quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

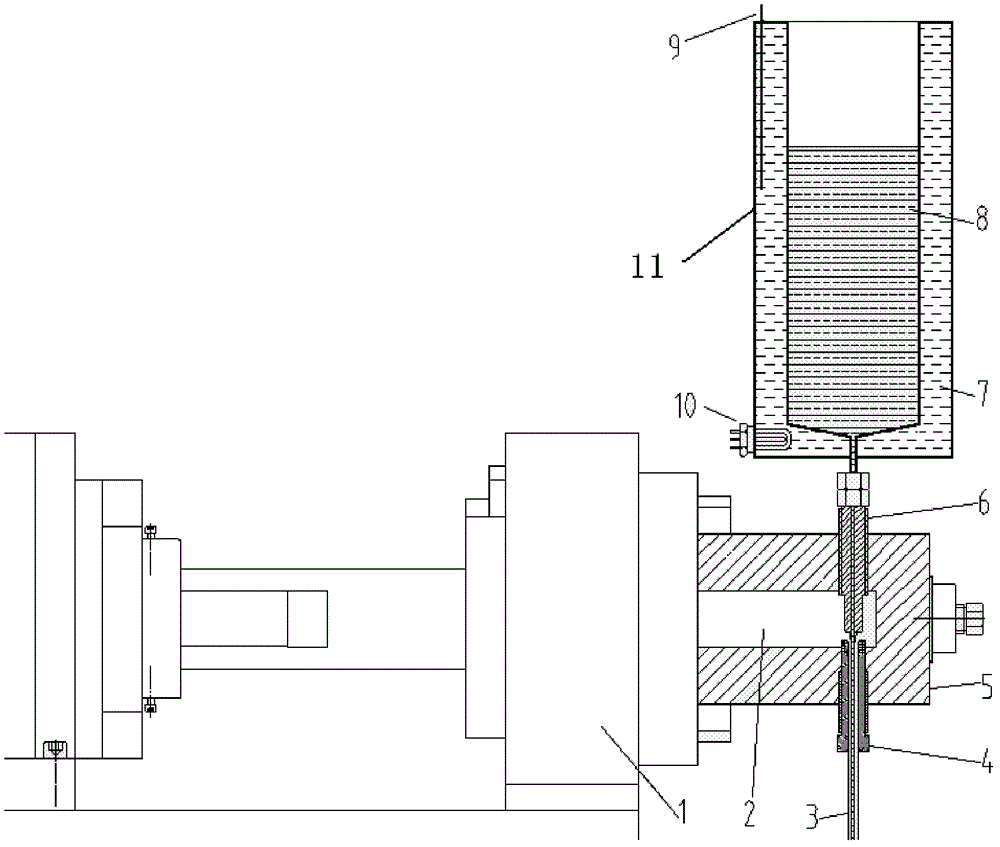

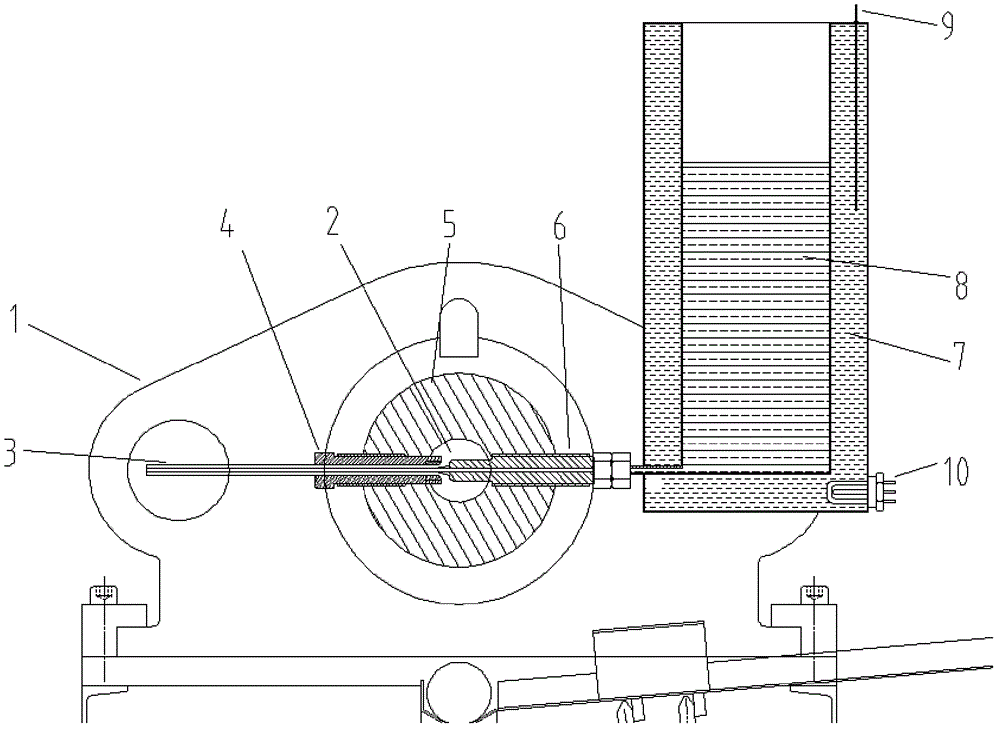

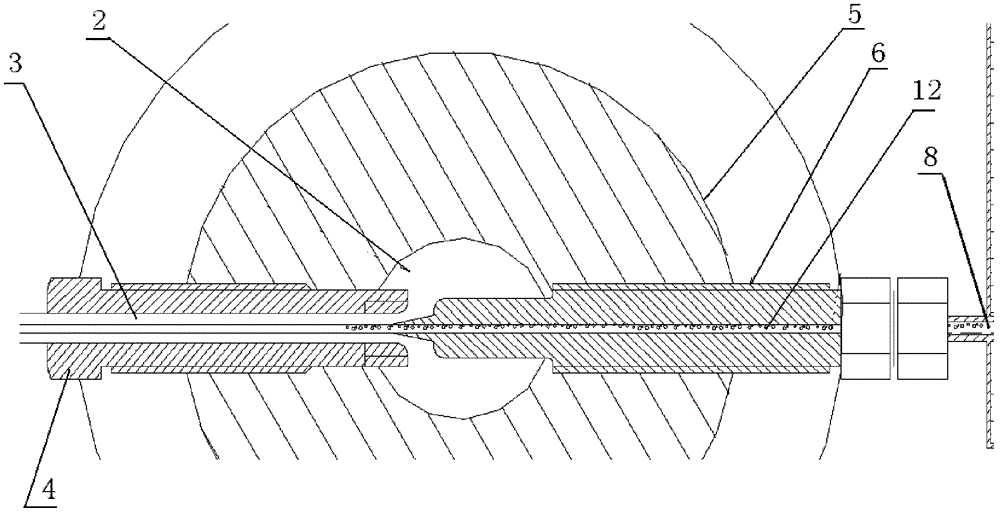

[0018] Such as figure 1 As shown, the tin wire solder flux vertical filling device includes an extruder 1, a solder barrel 11, a rosin nozzle 6, and the solder barrel includes a heat transfer oil 7, a thermocouple 9, and a heat pipe 10, and the heat transfer oil is used as a heat transfer medium to make the flux The temperature change is more stable. There is a channel at the bottom of the solder barrel to communicate with the rosin nozzle 6. The top of the rosin nozzle extends into the extrusion chamber 2 of the extrusion barrel 5 of the extruder, which is close to the outlet die of the tin wire. The solder barrel 11 is placed on the top of the extruder, the rosin nozzle extends vertically into the extrusion cavity of the tin rod, the flux 8 is injected into the rosin nozzle from the bottom of the solder barrel, and then the flux is injected into the flux hole in the center of the tin wire 3 by the rosin nozzle, Extruded from the tin wire outlet die 4 after extrusion, in ord...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com