Automobile hub abrasive flow deburring method

An automobile wheel hub and abrasive flow technology, which is applied to abrasives, used abrasives processing devices, metal processing equipment, etc., can solve the problems of reduced processing efficiency, high labor intensity, environmental pollution, etc. The effect of reducing labor intensity and cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0031] The method for deburring automobile wheel hub abrasive grain flow of the present invention comprises:

[0032] Step 1: Install the wheel hub on the precision deburring and finishing equipment of the automobile wheel hub abrasive flow;

[0033] Step 2: configure the viscoelastic abrasive flow with controllable rheological properties, and introduce the abrasive flow into the precision deburring and finishing processing equipment of the automobile wheel hub abrasive flow;

[0034] Step 3: Control the abrasive flow to rough the hub;

[0035] Step 4: Control the abrasive flow and then finish the rough machined hub;

[0036] Step 5: Processing to complete the processing procedure.

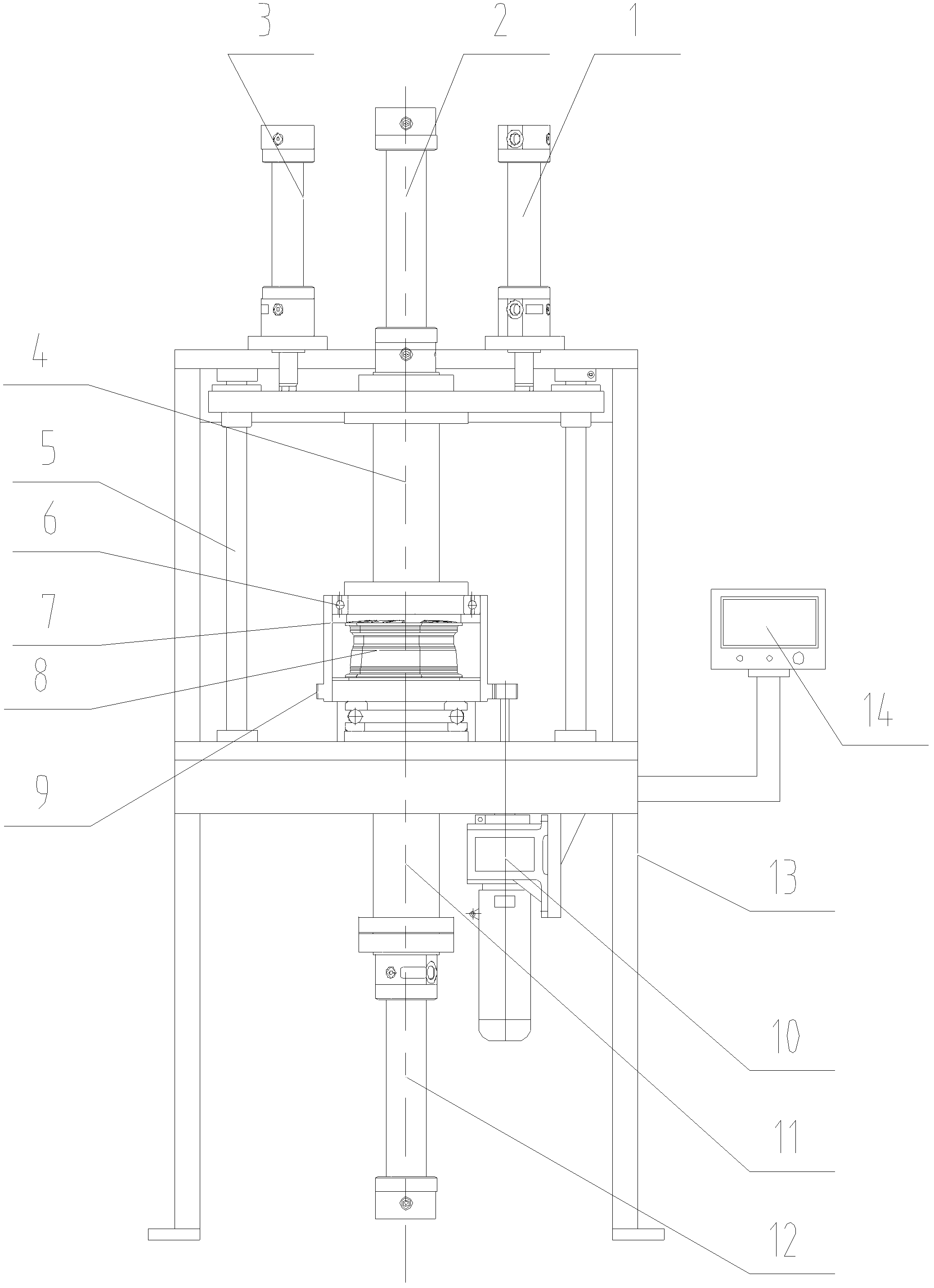

[0037] Such as figure 1 As shown, the precision deburring and finishing processing equipment for automobile wheel hub abrasive flow in the step 1 includes a frame 13, and the top of the frame 13 is symmetrically provided with a left push cylinder 1 and a right push cylinder 3, and the An upper...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com