Vertical lump making machine and working method thereof

A lump-making machine and vertical technology, applied in the field of vertical lump-making machines, can solve problems such as unevenness of quartz glass, impact on the quality of finished quartz lumps, difficulty in automatic production of lump-making machines, etc., and achieve a compact structure that is conducive to automation Produce and improve the effect of eccentric load defects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

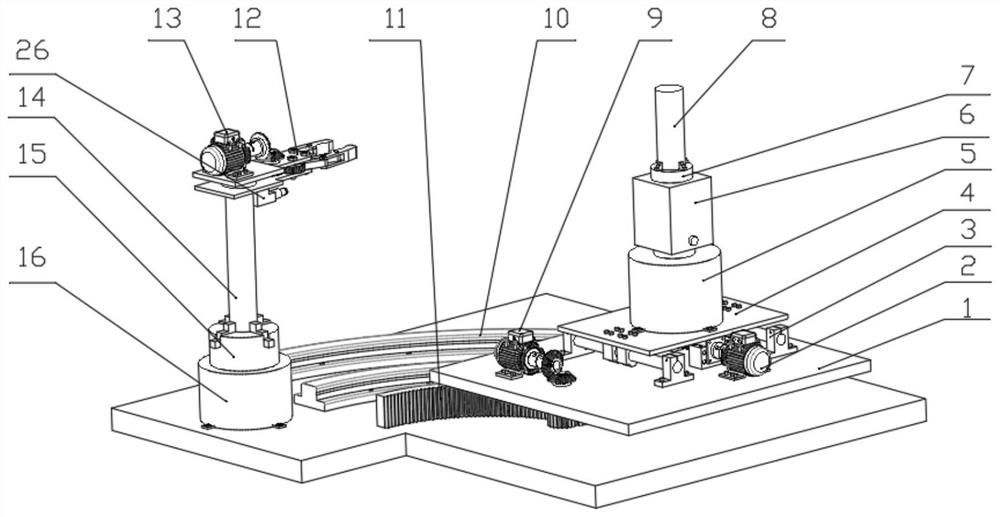

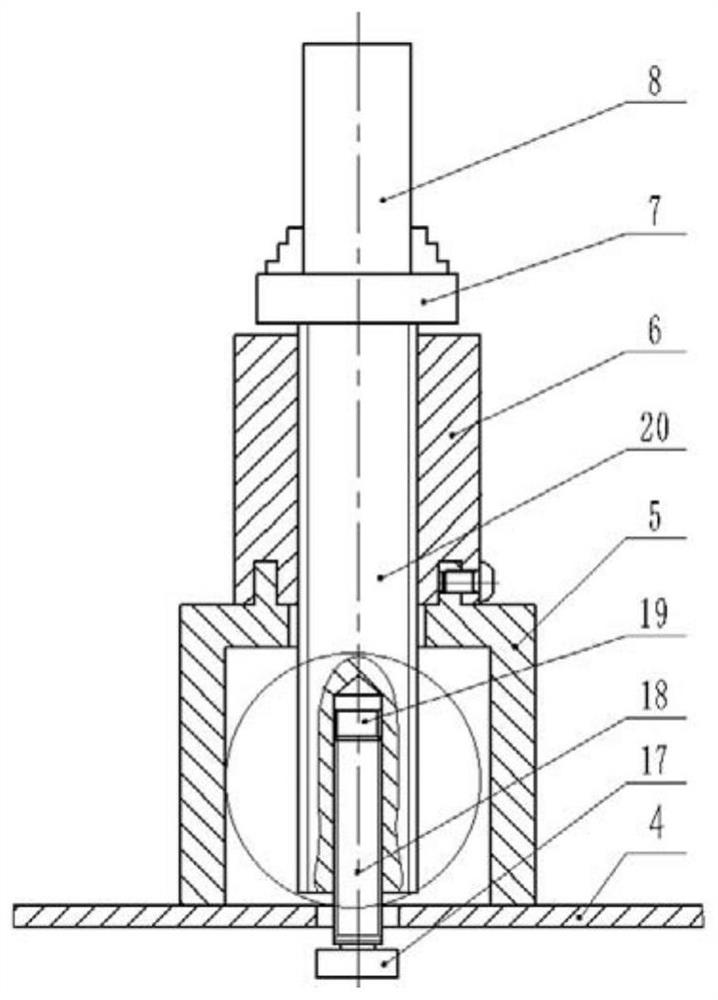

[0055] Such as Figure 1-Figure 4 As shown, the structure and working principle of a kind of vertical lump making machine of the present invention are shown:

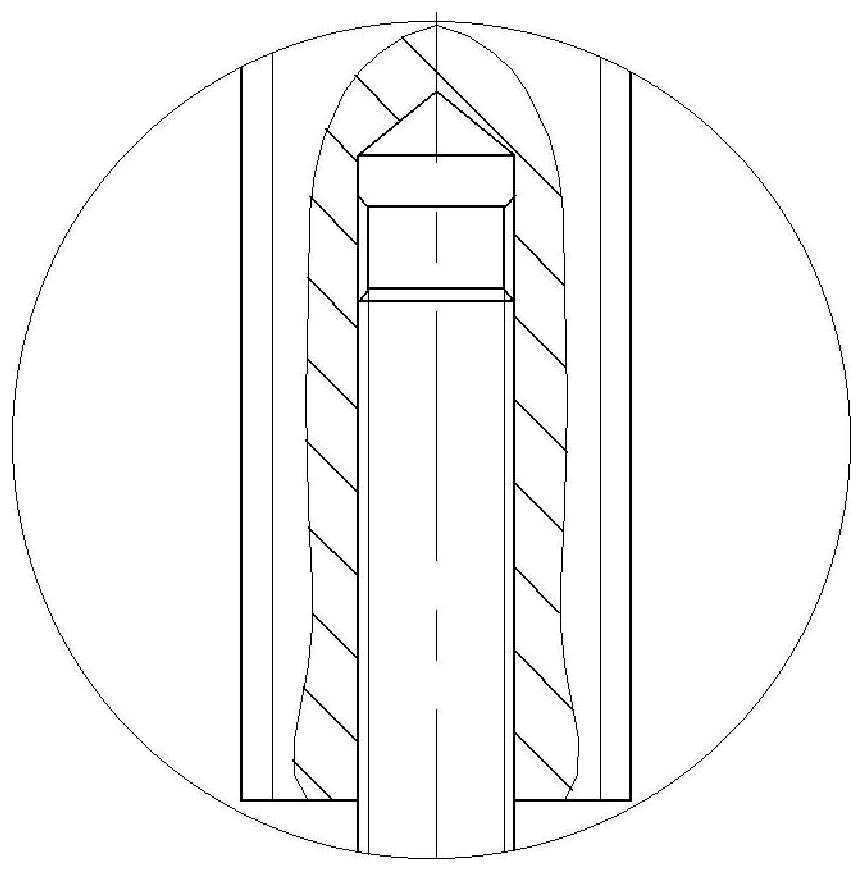

[0056] The vertical lump making machine of the present invention is mainly composed of four parts: a lifting and rotating mechanism, a swing mechanism, a rotating mechanism and a discharge mechanism. The lifting and rotating mechanism includes a lifting and rotating motor 17, a sliding key shaft 18, a lifting and rotating rod 20, a lifting base 5 and a lifting nut 6, and the lifting and rotating motor 17 is fixed on the sliding platform 4, and the lifting and rotating motor 17 drives the sliding key The shaft 18 rotates, and the feather key shaft 18 is inserted into the feather key hole 19 below the lifting rotating rod, and the feather key shaft 18 drives the lifting rotating rod 20 to rotate through the sliding key, and the feather key shaft 18 can be in the Slide up and down in the feather key hole 19 below the lift...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com