Molding system for preparing three-dimensional micro-porous bone bracket from high polymer

A technology of microporous and bone scaffolds, which is applied in the field of rapid prototyping system of artificial bone scaffolds, can solve the problems of difficult to meet performance requirements, low precision of molded bone scaffolds, high surface roughness, etc., achieve fast speed, realize structural optimization and bionics Design, high resolution effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0027] The present invention will be further described below in conjunction with the accompanying drawings and specific embodiments.

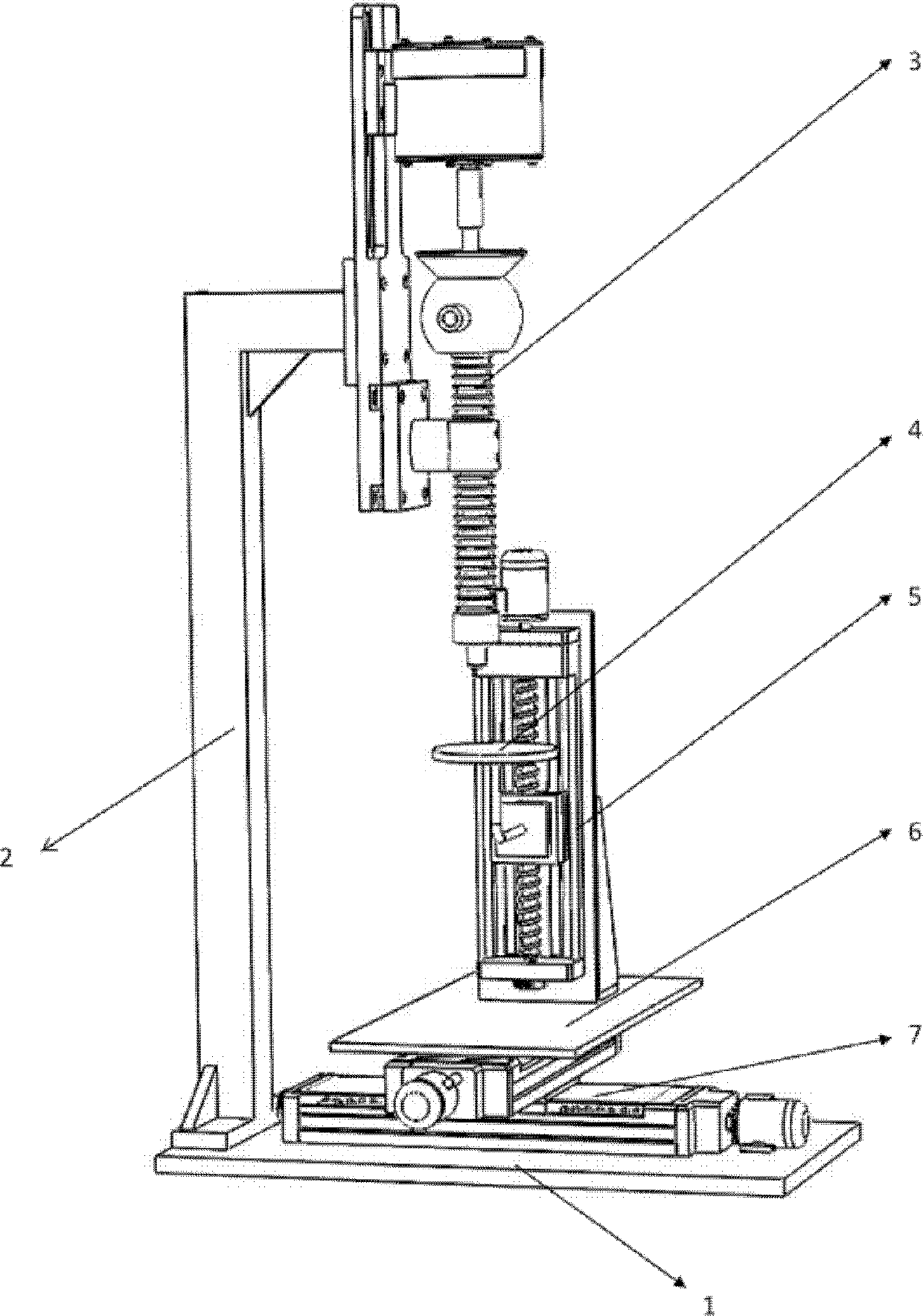

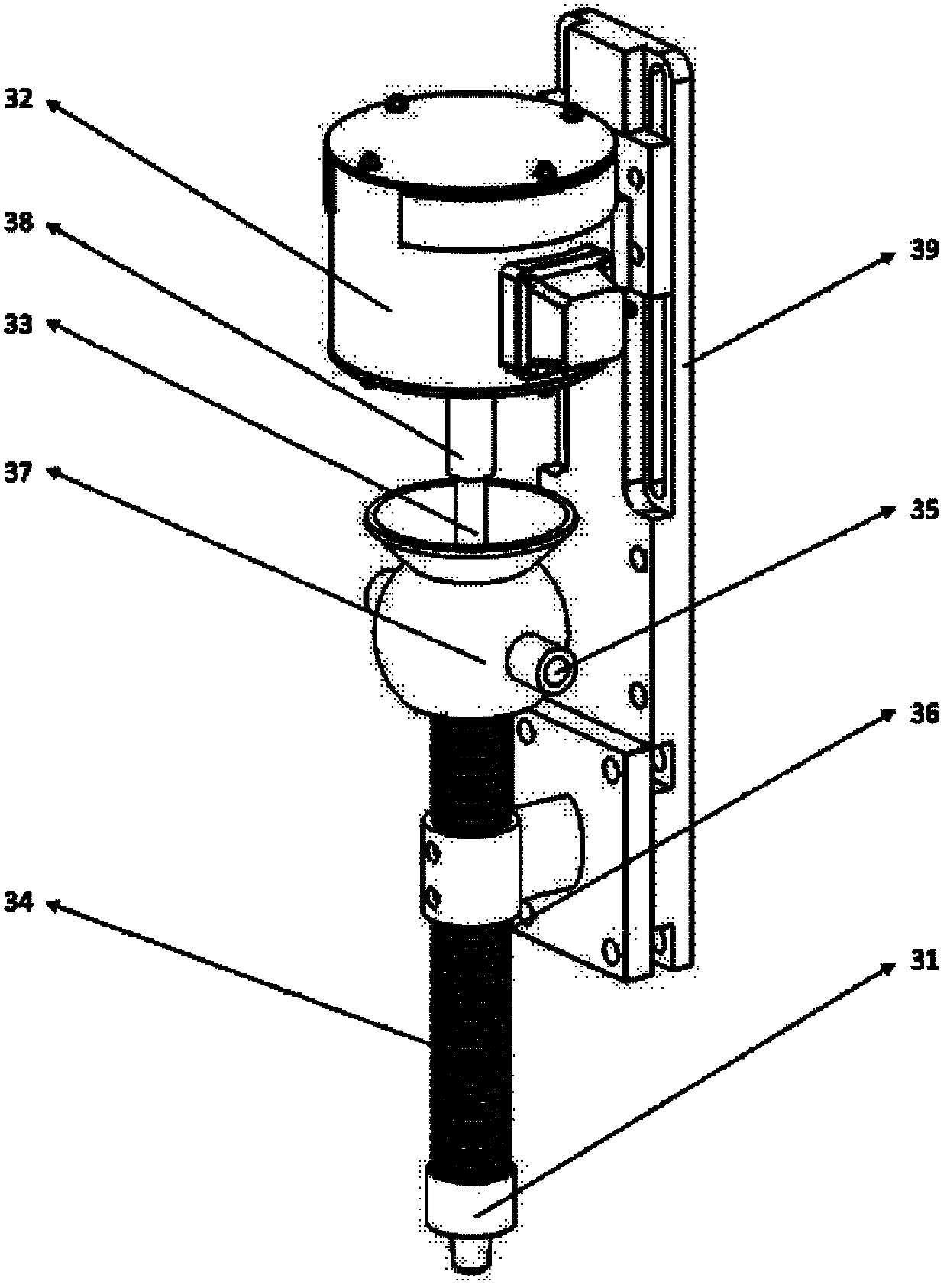

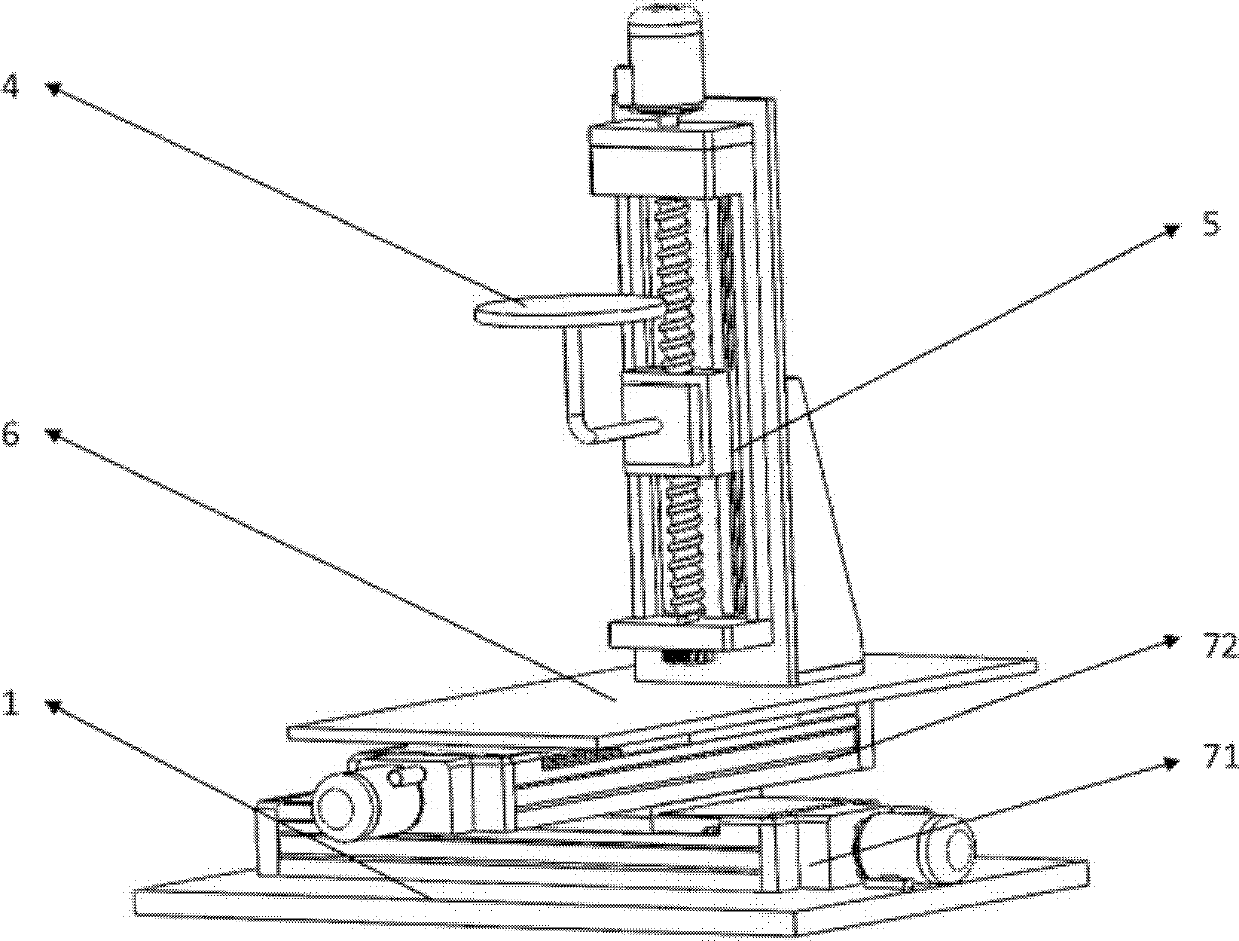

[0028] see figure 1 , figure 2 , image 3 with Figure 4 , the base 1 is provided with a bracket 2, and the base 1 is also provided with a plane movement mechanism 7 in the x-y direction, and a forming support plate 6 is installed on the plane movement mechanism 7 in the x-y direction. The vertical lifting mechanism 5 is equipped with a forming platform 4 on the vertical lifting mechanism 5 in the z direction, the extrusion unit 3 is installed on the support 2 and the nozzle 31 of the extrusion unit 3 extrudes and solidifies the molten material in a filament form on the forming platform 4, the structure of the extruding unit 3 is that a melting tank 36 and an extrusion motor 32 are installed on the connecting plate 39, and an extruding screw 33 is arranged in the melting tank 36, and the extruding screw 33 is connected with the extruder thr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com