Bionic cellular tire

A bionics and honeycomb technology, applied to tire parts, non-pneumatic tires, transportation and packaging, etc., can solve the problems of severe air expansion and contraction, poor environmental adaptability, easy air leakage, etc., and achieve superior frictional heat generation of tires , High structural strength of the wheel, superior effect of noise suppression

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0015] The present invention will be further described below in conjunction with the accompanying drawings and embodiments.

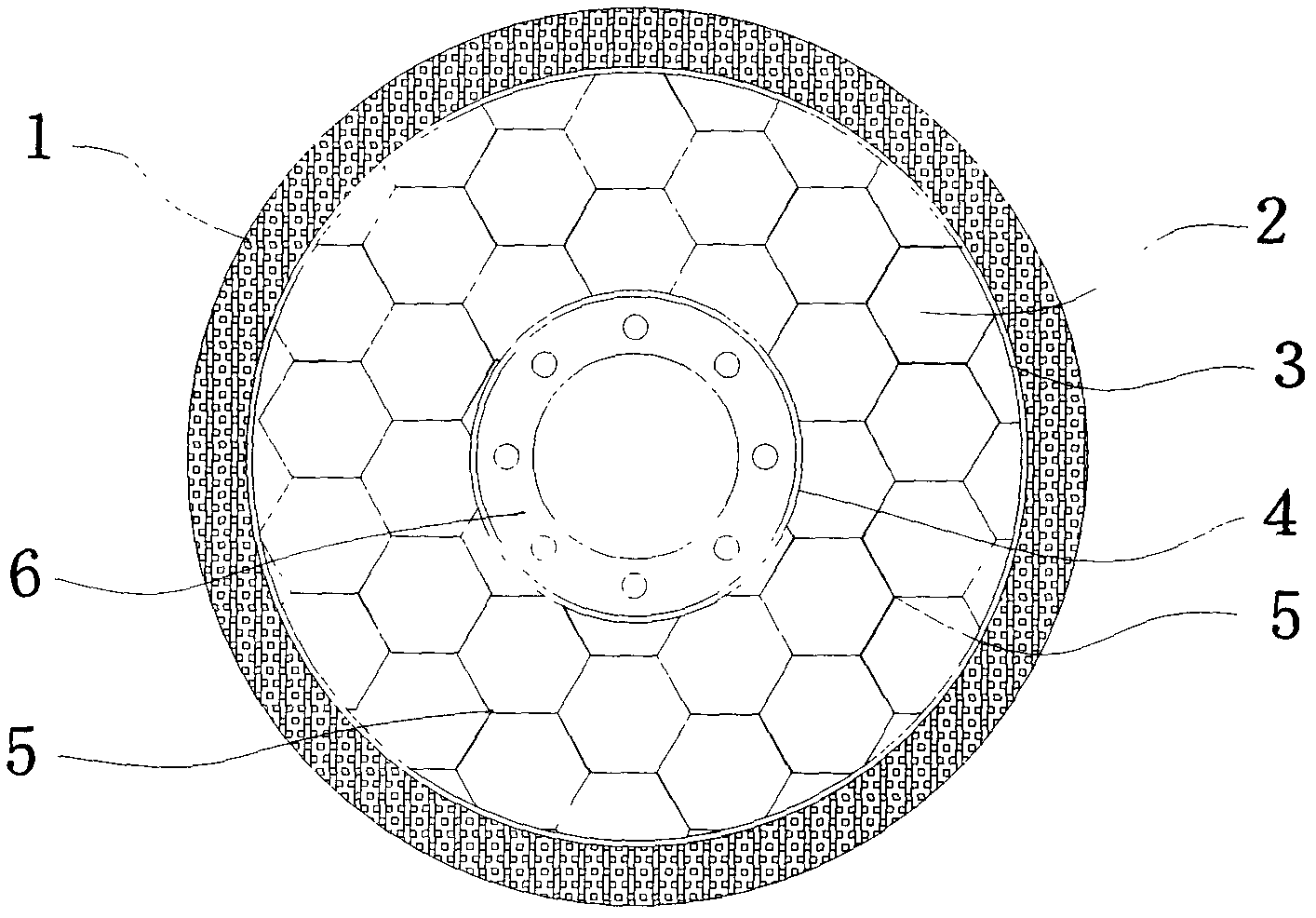

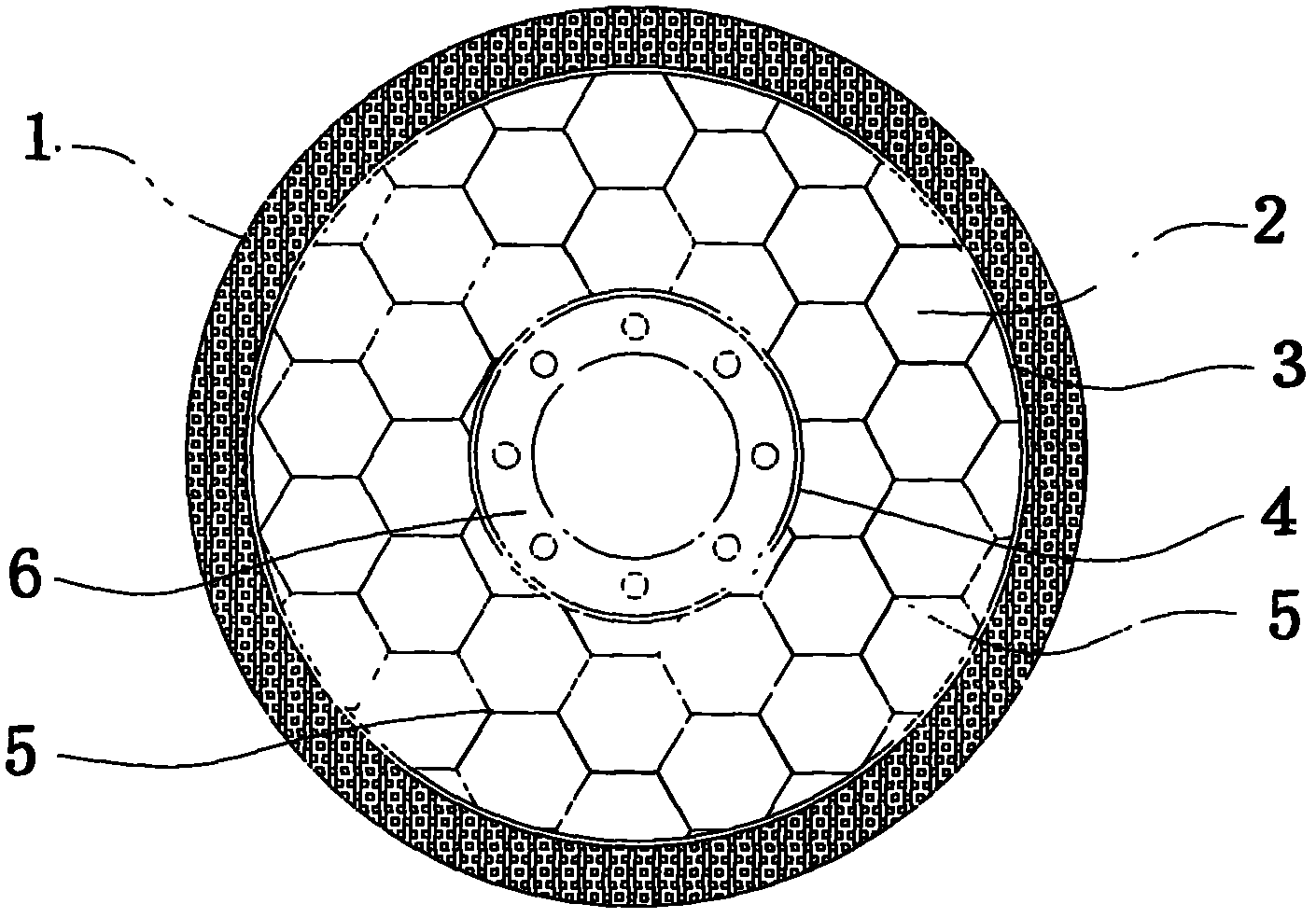

[0016] Examples, see figure 1 Shown:

[0017] The present invention is a bionic honeycomb tire, comprising a solid tire 1 and a honeycomb carcass 2, the solid tire 1 is made of ordinary vulcanized rubber, and is tightly hooped on the periphery of the honeycomb carcass 2 through interference fit, and the honeycomb carcass 2 includes The outer ring 3 , the inner ring 4 and several honeycomb columnar structures 5 arranged between the outer ring 3 and the inner ring 4 .

[0018] The honeycomb carcass 2 is made of high-strength polymers, such as synthetic polyester fibers. Of course, the present invention is not limited to synthetic polyester fibers. Other materials that are beneficial to the realization of the object of the present invention can be used, such as polyaramid, High-strength polyimide fiber, polyphenylene benzobisoxazole (PBO) fiber, ultra-hi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com