Wrapping machine

A technology for balers and straps, which is applied to the parts of strapping machines and strapping materials, etc. It can solve the problem of not being able to meet the requirements of the strapping speed at the same time, the force of the straps, the lack of monitoring, adjustment and control functions, and the impact on the efficiency of the whole machine, etc. problems, to achieve the effect of timely monitoring and adjustment of belt movement, matching performance, and ensuring work stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

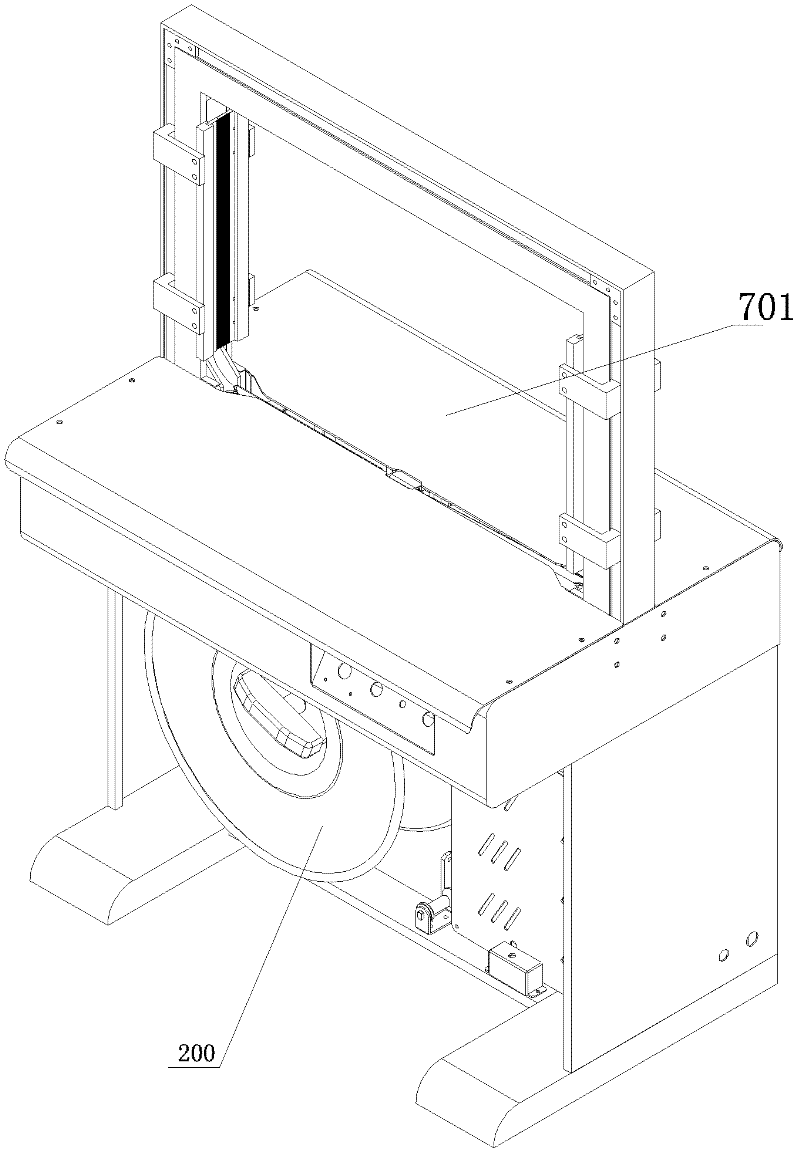

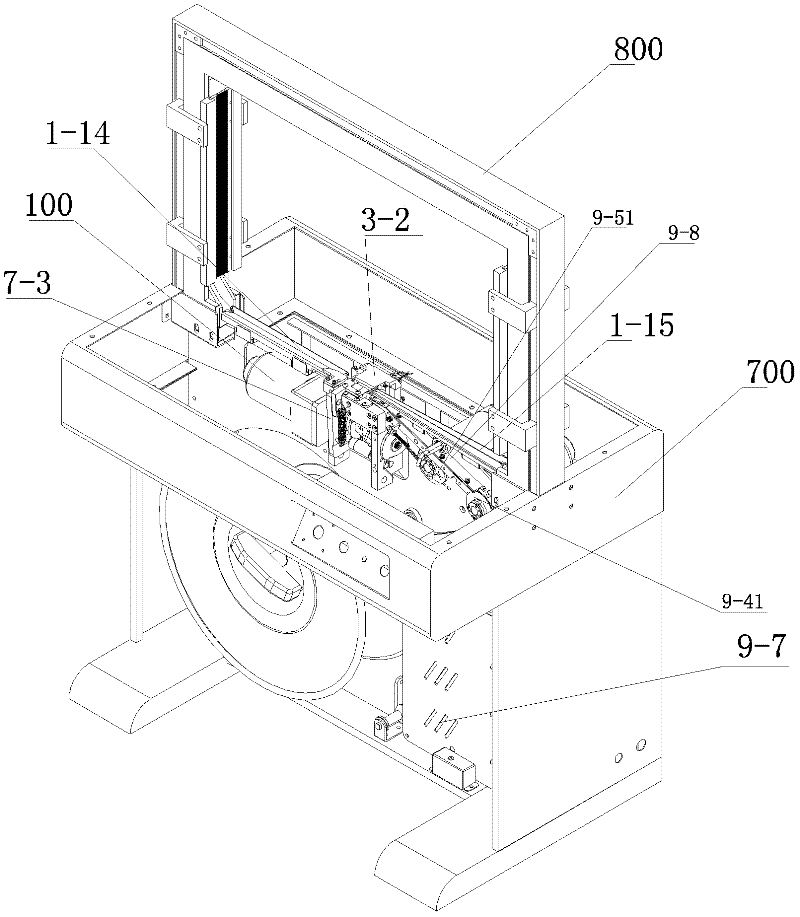

[0054] The lower half of the baler provided by the present invention is provided with a vertical mounting plate 400, and its upper half is provided with a fixed frame 800, and the mounting plate 400 and the fixed frame 800 are installed on the baler frame 700, A wire reel 200 is also provided at the bottom of the baler.

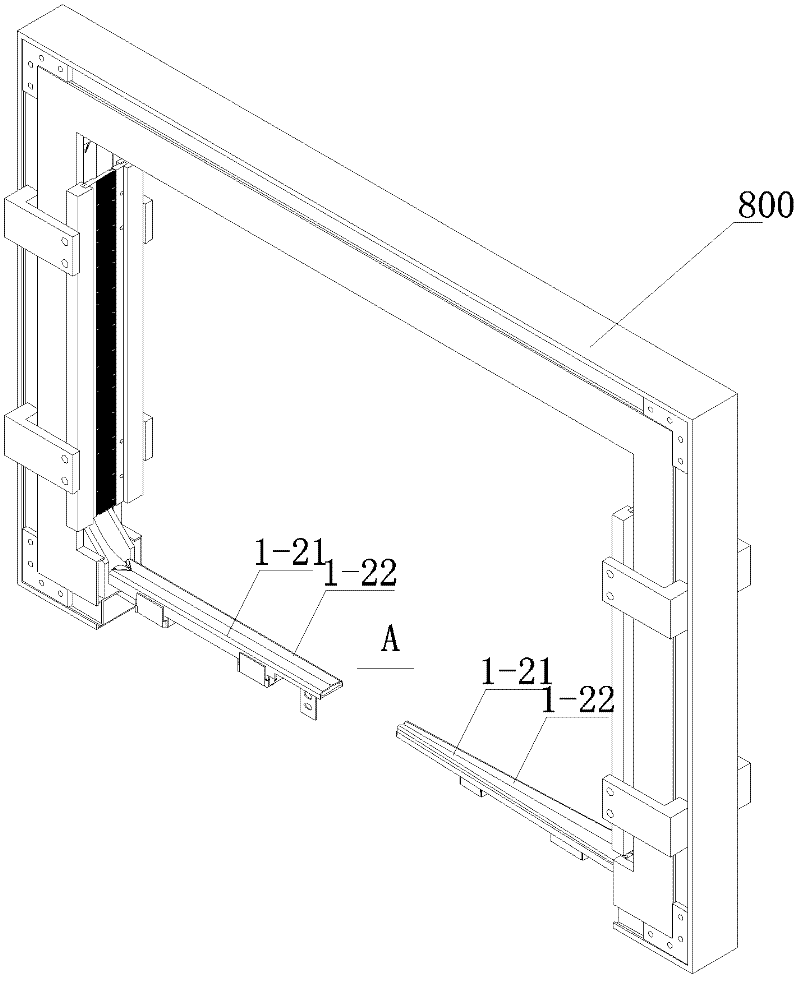

[0055] Refer to attached Figure 3-5 . The baler is provided with an upper beltway 1-11, a left beltway 1-12, a right beltway 1-13, a left lower beltway 1-14, and a right lower beltway 1-15, which constitute the A-position beltway around the article. , between the upper beltway 1-11 and the left beltway 1-12 and the right beltway 1-13, between the left beltway 1-12 and the left lower beltway 1-14, and the right beltway 1-13 and the right lower beltway Corner transition blocks 1-4 are respectively provided between lanes 1-15, and corner transition blocks 1-4 are provided with transition belt grooves 1-40, and the left and right of the belt lanes are the left...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com