Assembled packaging shelf for transporting unit plates of curtain wall

A curtain wall unit and assembled technology, applied in the field of packaging shelves, can solve the problems of low forklift operation efficiency and waste of steel, and achieve the effects of improving forklift operation efficiency, saving steel, and reasonable structural design

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

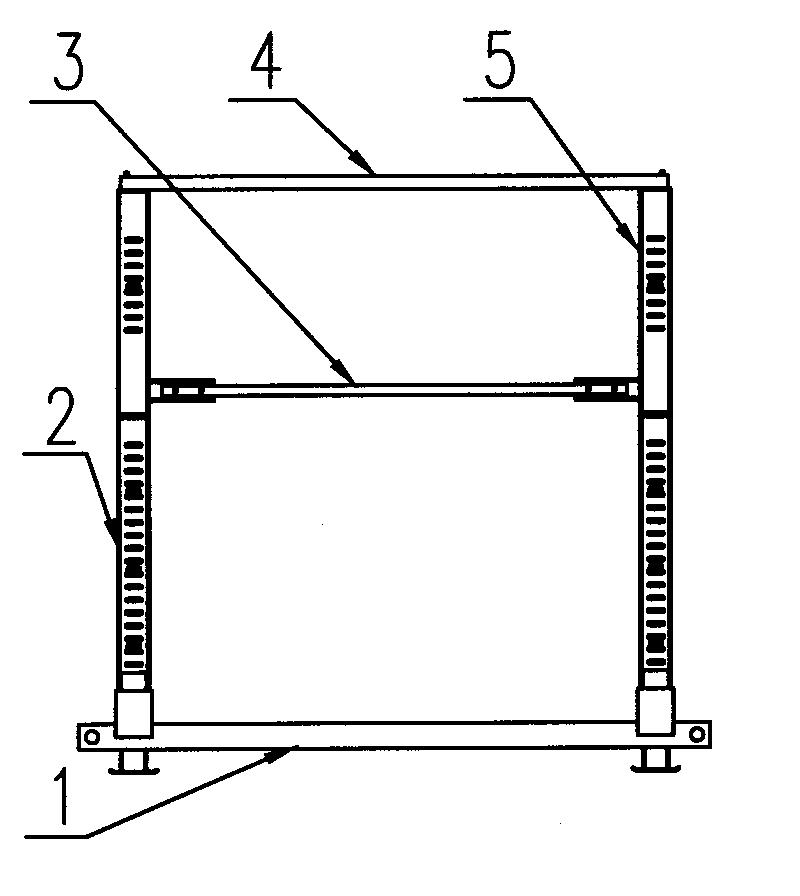

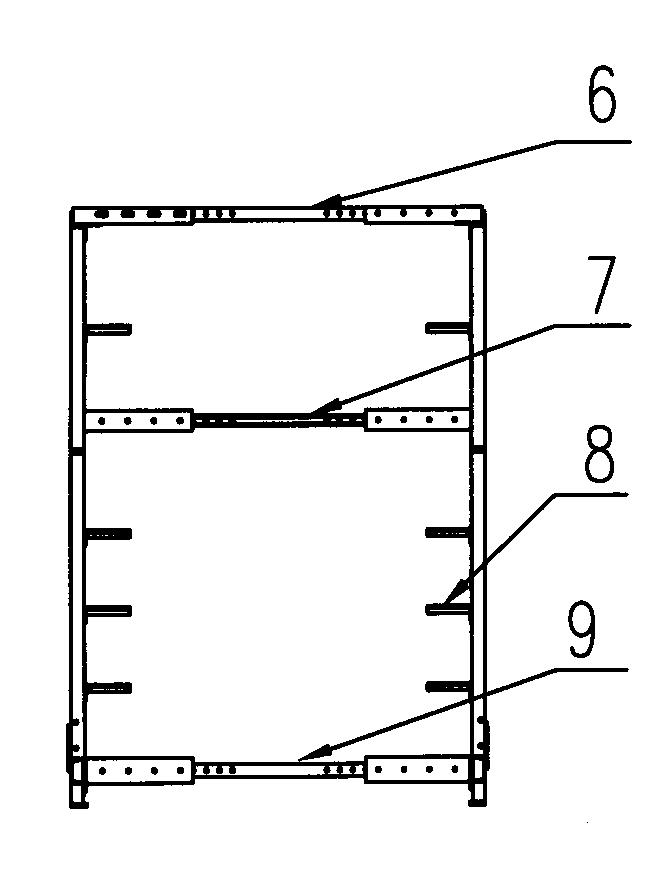

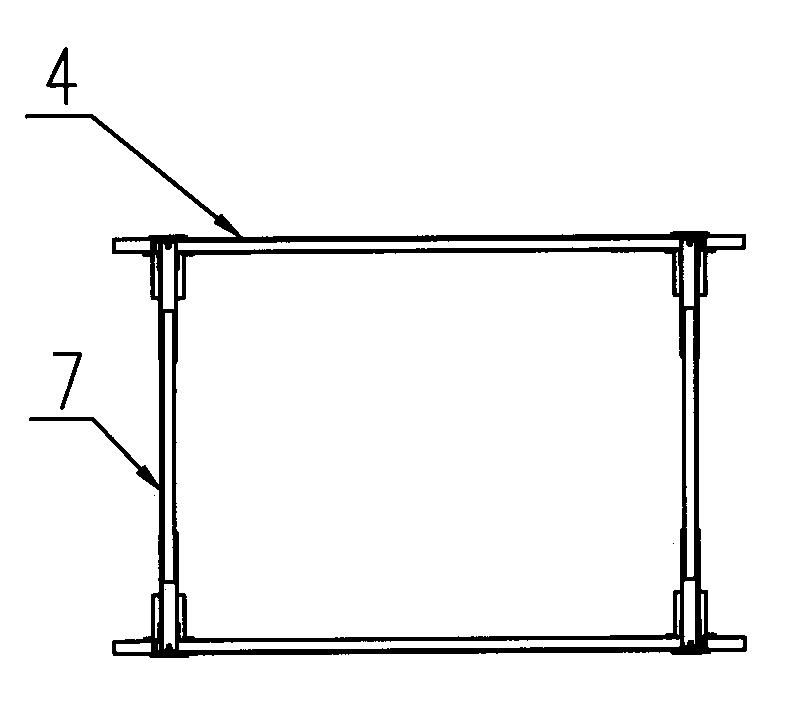

[0017] according to Figure 1~5 The specific structure of the present invention will be described in detail. The assembled packaging shelf for transporting curtain wall unit panels includes a bottom fixing base 1, a column assembled on the bottom fixing base 1, an adjusting beam and a tie rod, and a connecting bolt assembly for assembling various parts. Wherein the bottom fixing seat 1 is an integral structure assembled by the left and right bottom beams with bottom legs and connecting ferrules and the bottom adjustment beam 9 . Lifting holes are provided at the two ends of the left and right bottom beams of the bottom fixing base 1, which can be used for on-site hoisting shelves. The two ends of the lower adjusting beam 9 are respectively processed with connection holes, and the hole spacing of each connection hole corresponds to the hole spacing on the connecting beams distributed on the inside of the left and right bottom beams, so as to adjust the distance between the two...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com