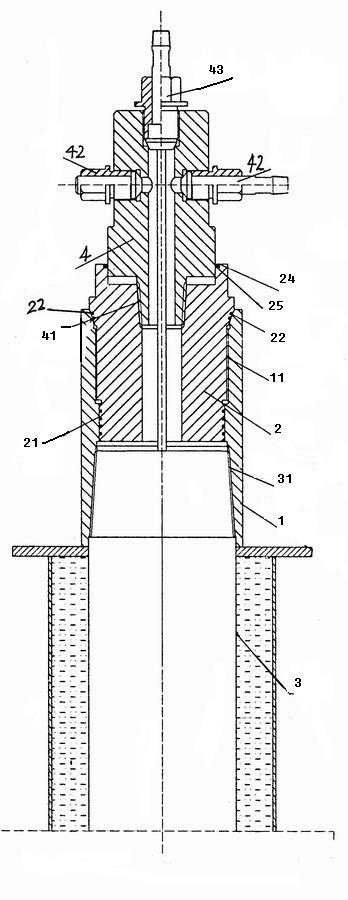

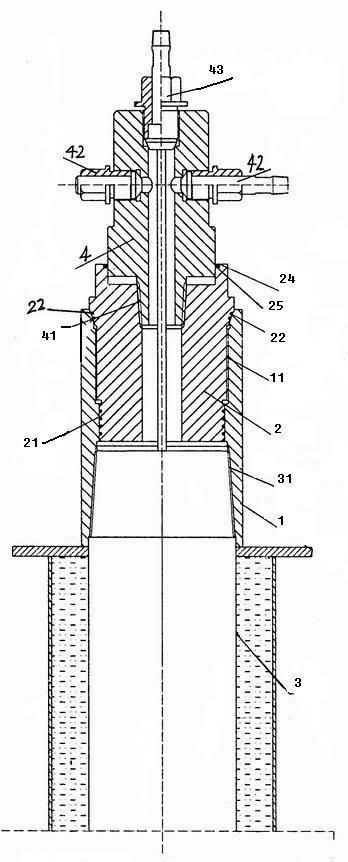

Multi-stage sealing adjustable full-bore type wellhead device

A wellhead device and adjustable technology, applied in storage devices, transportation and packaging, etc., can solve the problems of high cost, large volume, difficult installation, etc., and achieve the effect of light weight, low processing cost and simple on-site installation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0015] The multi-stage sealed adjustable full-bore wellhead device is characterized by: a conduit collar 1, an upper head 2, and an intake and exhaust joint 4, the lower part of the conduit collar 1 is connected to the API conduit 3 through a thread 31, and the upper part of the conduit collar 1 It is connected with the upper head 2 through straight thread 11; the connection between the upper head 2 and the conical platform at the lower end of the inlet and exhaust joint 4 is sealed with a tapered thread 41, and the lower end of the upper head 2 is provided with 4 "O" type seals Ring 21, the outer ring of the upper end of the upper head 2 has a sealing slope 22, and there are two "O"-shaped sealing rings 23 on the sealing slope 22, and the upper end of the upper head 2 is a protruding ring 24, the ring The internal test of 24 has waterproof rubber ring 25, and intake and exhaust joint 4 is provided with intake and exhaust port 42 and sewage discharge port 43.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com