Position correction device

A calibration and uniform technology, applied in the field of calibration devices, can solve problems affecting product quality, easy cracking, falling, etc., achieve the effect of smooth workpiece conveying process, and improve accuracy and efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

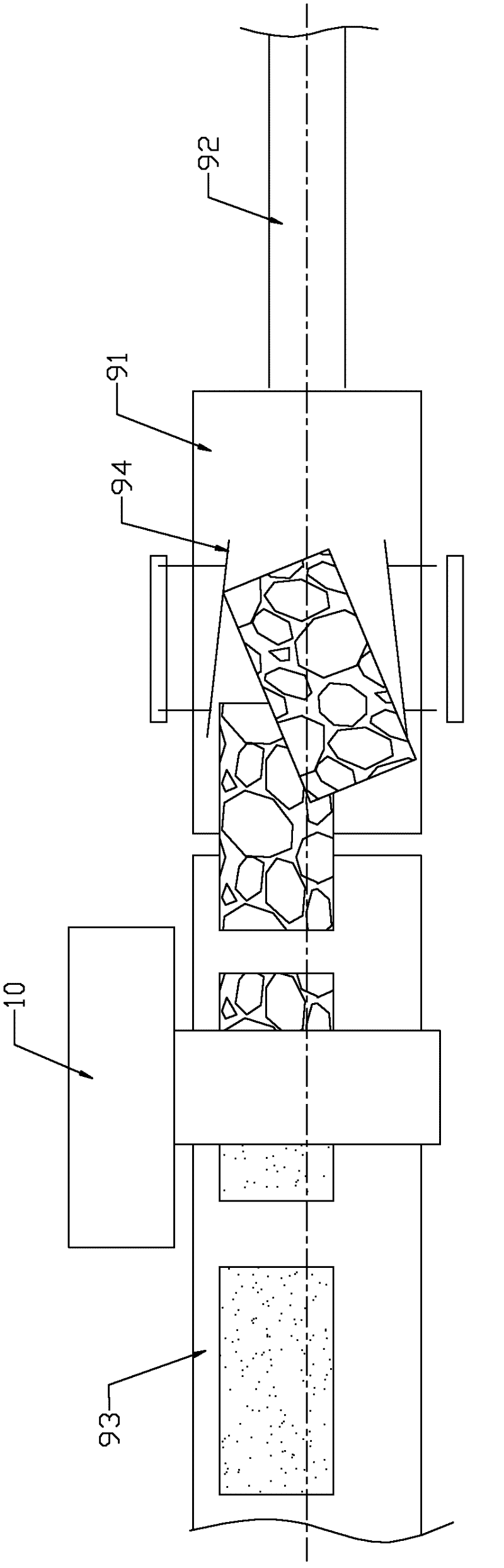

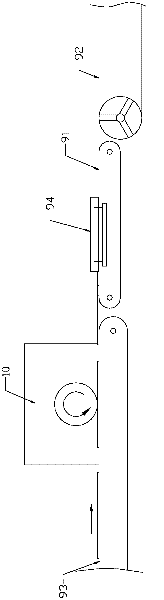

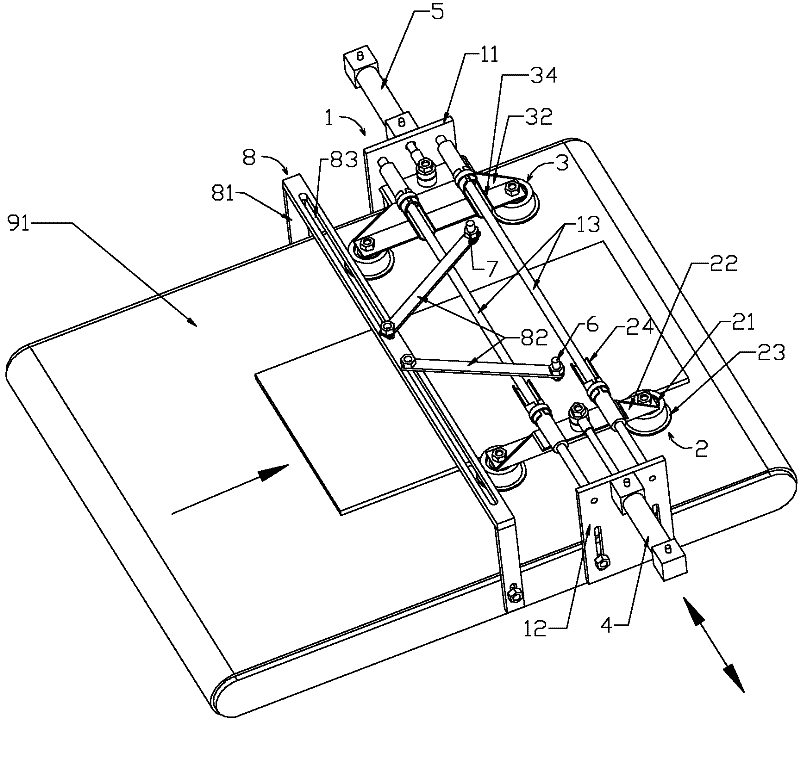

[0030] Figure 3-5 The brick correction device shown is an embodiment of the present invention, which includes a support 1, two sets of stoppers 2, 3 oppositely arranged, two sets of electric eyes 6, 7 for sensing the position of the workpiece, and a control system (not shown) And adjusting frame 8.

[0031] Wherein, the bracket 1 includes two installation side plates 11, 12 and more than two connecting guide rods 13 arranged parallel and horizontally.

[0032] The two groups of stoppers 2 and 3 have the same structure, taking the stopper 2 as an example: it includes two identical wheels 21 and mounting frames 22, and the two wheels 21 are arranged in a row and are rotatably mounted on the corresponding mounting frames 22 On the top, the axes of the two wheels 21 are set vertically; the two wheels 21 are respectively fixedly covered with a protective cover 23, and the protective cover 23 is composed of a lower part with a larger outer diameter and an upper part with a smaller...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com