Method for preparing peeled layered material/ carbon nano tube complex in aqueous solution

A technology of carbon nanotubes and layered materials, applied in the field of preparation of layered materials/carbon nanotube composite materials, can solve the problems of large environmental pollution, a large amount of toxic solvents, and aggravated particle agglomeration, and achieve good stability and non-toxicity Solvents, to avoid the effect of destruction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment 1

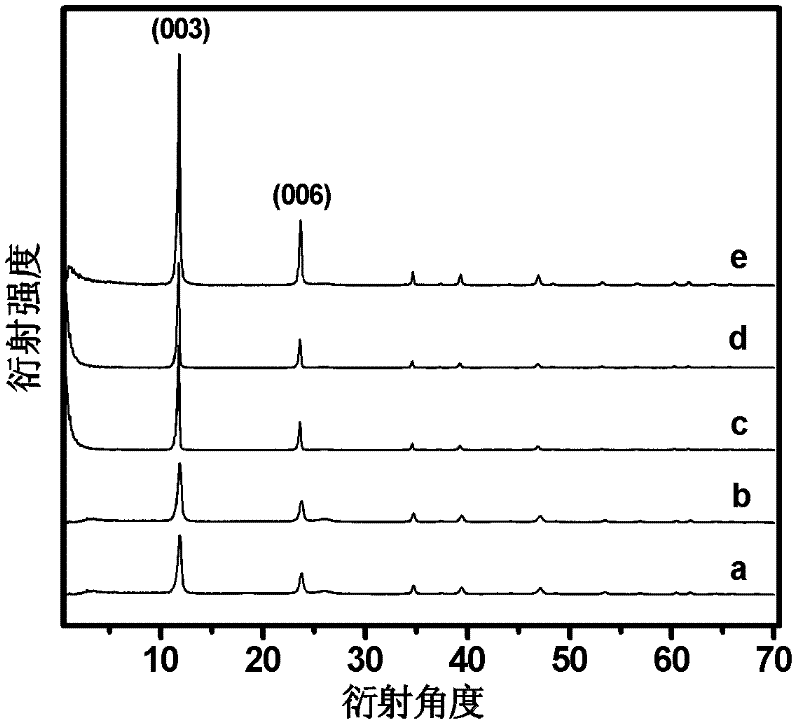

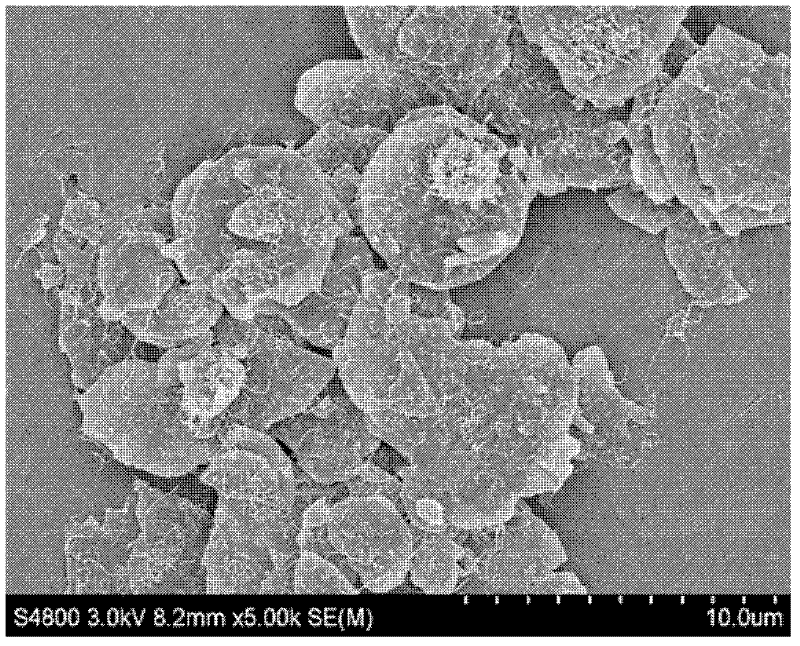

[0038] 0.87g cobalt nitrate, 0.56g aluminum nitrate, 0.63g urea and 0.1g multi-wall carbon nanotubes were dissolved in 300ml deionized water to obtain a reaction solution, wherein the concentrations of cobalt nitrate, aluminum nitrate, urea and multi-wall carbon nanotubes were respectively Controlled at 10mmol / L, 5mmol / L, 33mmol / L and 0.3mg / ml. The above reaction solution was added into a three-necked flask, stirred at 70° C. for 6 h, filtered with suction and dried at room temperature for 3 h to obtain an unexfoliated LDH / CNT complex.

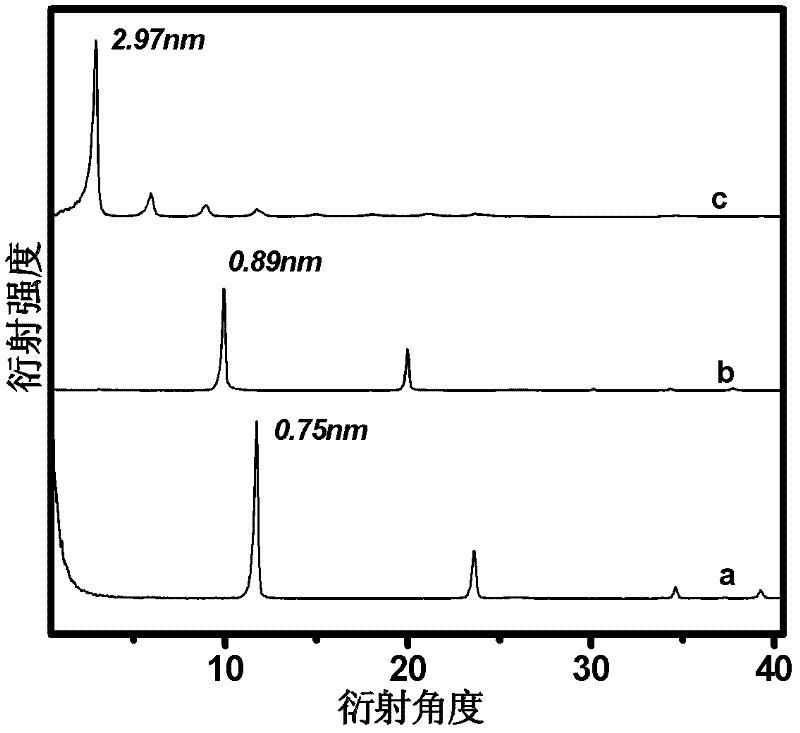

[0039] Add 1 g of the above product into 500 ml of a mixed aqueous solution of nitric acid and sodium nitrate, control the concentration of nitric acid to 1 mmol / L, and the concentration of sodium nitrate to 3.3 mol / L, stir for 24 hours, then suction filter and dry at room temperature for 5 hours to obtain the product Add it to an aqueous solution of sodium dodecylbenzenesulfonate with a concentration of 4 mmol / L, stir at 50° C. for 24 h, filt...

Embodiment 2

[0049] 2.38g of cobalt chloride, 0.665g of aluminum chloride, 0.63g of urea and 0.5g of multi-walled carbon nanotubes were dissolved in 300ml of deionized water to obtain a reaction solution, wherein cobalt chloride, aluminum chloride, urea and multi-walled carbon nanotubes The concentrations of the tubes were controlled at 10mmol / L, 5mmol / L, 33mmol / L and 1.5mg / ml respectively. The above reaction solution was added into a three-necked flask, stirred at 50° C. for 24 h, filtered with suction and dried at room temperature for 5 h to obtain a LDH / CNT complex.

[0050] Add 1 g of the above product into 500 ml of a mixed aqueous solution of nitric acid and sodium nitrate, control the concentration of nitric acid to 1 mmol / L, and the concentration of sodium nitrate to 3.3 mol / L, stir for 20 h, then suction filter and dry at room temperature for 5 h to obtain the product Add it to an aqueous solution of sodium dodecylbenzenesulfonate at a concentration of 10 mmol / L, stir at 60°C for ...

Embodiment 3

[0058] 16.86g of cobalt sulfate, 10.26g of aluminum sulfate, 1ml of ammonia and 1g of multi-walled carbon nanotubes were dissolved in 300ml of deionized water to obtain a reaction solution, wherein the concentrations of cobalt sulfate, aluminum sulfate, ammonia and of multi-walled carbon nanotubes were controlled at 60mmol / L, 30mmol / L, 200mmol / L and 3mg / ml. The above reaction solution was added into a three-necked flask, stirred at 100° C. for 12 h, filtered with suction and dried at room temperature for 8 h to obtain an unexfoliated LDH / CNT complex.

[0059] Add 1g of the above product into 500ml of mixed aqueous solution of nitric acid and sodium nitrate, control the concentration of nitric acid and sodium nitrate to 2mmol / L and 5mol / L respectively, stir for 18h, then filter with suction and dry at room temperature for 8h, after obtaining the product, add the concentration In 20mmol / L sodium dodecyl sulfate aqueous solution, stirred at 70°C for 8h, filtered with suction and ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com