High-Curie temperature (Tc) lead-free positive temperature coefficient (PTC) thermal sensitive ceramic material

A technology of heat-sensitive ceramics and raw materials, applied in the field of semiconductor ceramic materials, can solve the problems of few reports on the results of heat-sensitive ceramic temperature control materials, and achieve the effect of avoiding the harm of lead to the environment and human body.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

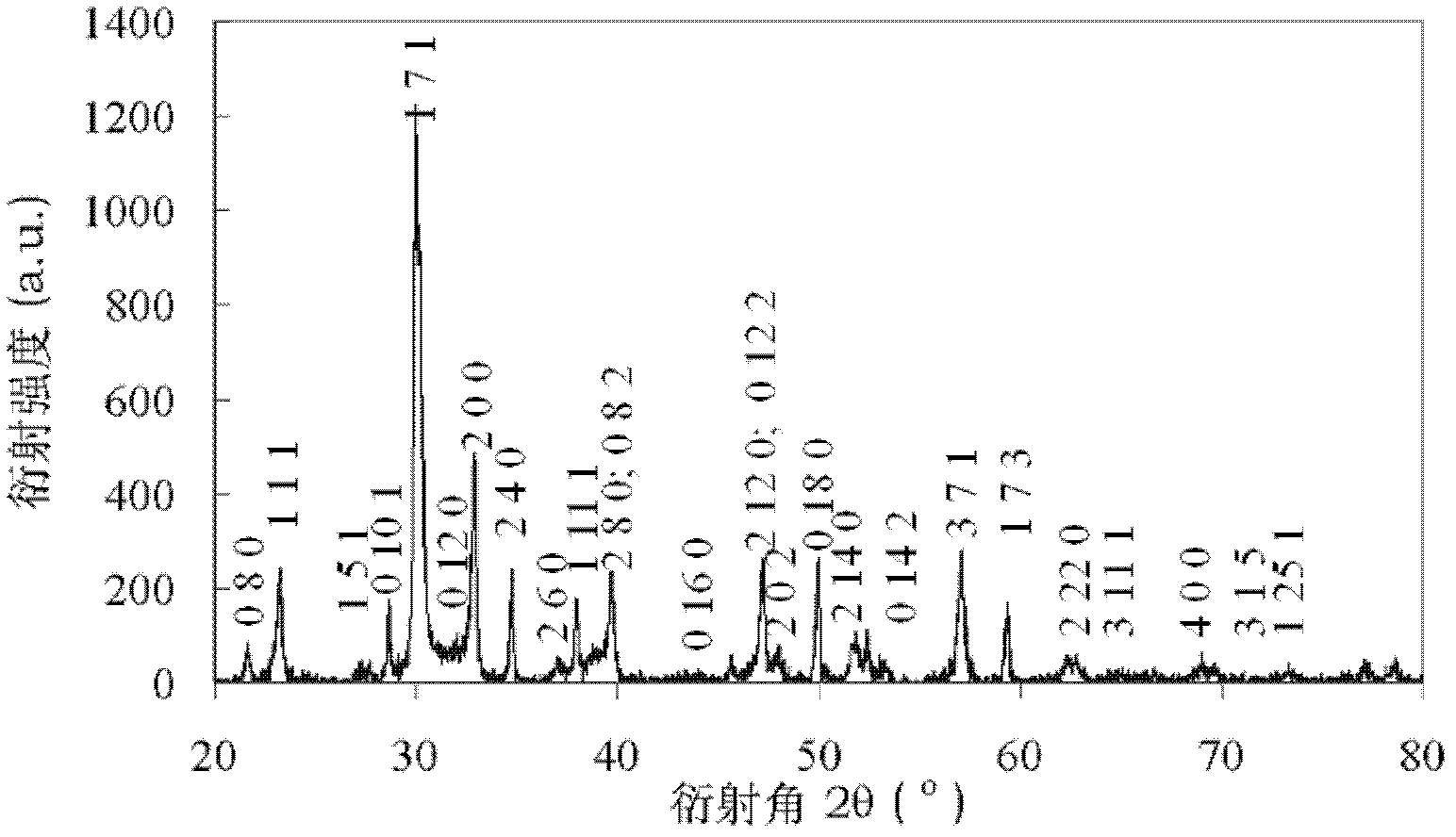

Image

Examples

Embodiment 1

[0021] The present embodiment main component is by molecular formula (Bi 1-x / 2 K x / 2 )(Zn 1 / 2-x / 2 sn 1 / 2-x / 2 Ti x )O 3 Carry out batching, wherein x=0.8, promptly main component can be simplified as (Bi 0.6 K 0.4 )(Zn 0.1 sn 0.1 Ti 0.8 )O 3 ; The semiconducting element selects W with a valence of +6 +6 , the purpose is to make it to ABO 3 Type perovskite structure B lattice position for semiconducting doping, W +6 The ion content accounts for 0.1 mol% of the total molar amount of Zn, Sn and Ti. The initial raw material is selected from Bi 2 o 3 、K 2 CO 3 , ZnO, Sn, [CH 3 (CH 2 ) 3 O] 4 Ti, H 2 WO 4 . Material preparation is carried out according to the technological steps of following experiment:

[0022] ①Press the initial raw material according to (Bi 0.6 K 0.4 )(Zn 0.1 sn 0.1 Ti 0.8 )O 3 +0.001H 2 WO 4 Formula ingredients, weighing 23.022g Bi 2 o 3 , 4.507g K 2 CO 3 , 1.328g ZnO, 1.986g Sn, 44.394g[CH 3 (CH 2 ) 3 O] 4 Ti and 0.043g H ...

Embodiment 2

[0034] The present embodiment main component is by molecular formula (Bi 1-x / 2 K x / 2 )(Zn 1 / 2-x / 2 sn 1 / 2-x / 2 Ti x )O 3 The batching is carried out, wherein x=0.7; W is selected as the semiconducting element, which accounts for 0.1 mol% of the total molar amount of Zn, Sn and Ti. The initial raw material is selected from Bi 2 o 3 、K 2 CO 3 , ZnO, Sn, [CH 3 (CH 2 ) 3 O] 4 Ti, H 2 WO 4 . Material preparation is carried out according to the technological steps of following experiment:

[0035] ①Press the initial raw material according to (Bi 0.65 K 0.35 )(Zn 0.15 sn 0.15 Ti 0.7 )O 3 +0.001H 2 WO 4 Formula ingredients, weighing 25.829g Bi 2 o 3 , 4.085g K 2 CO 3 , 2.062g ZnO, 3.007g Sn, 40.229g[CH 3 (CH 2 ) 3 O] 4 Ti and 0.044g H 2 WO 4 ;

[0036] ②The preparation process is the same as the steps ②~⑩ in Example 1.

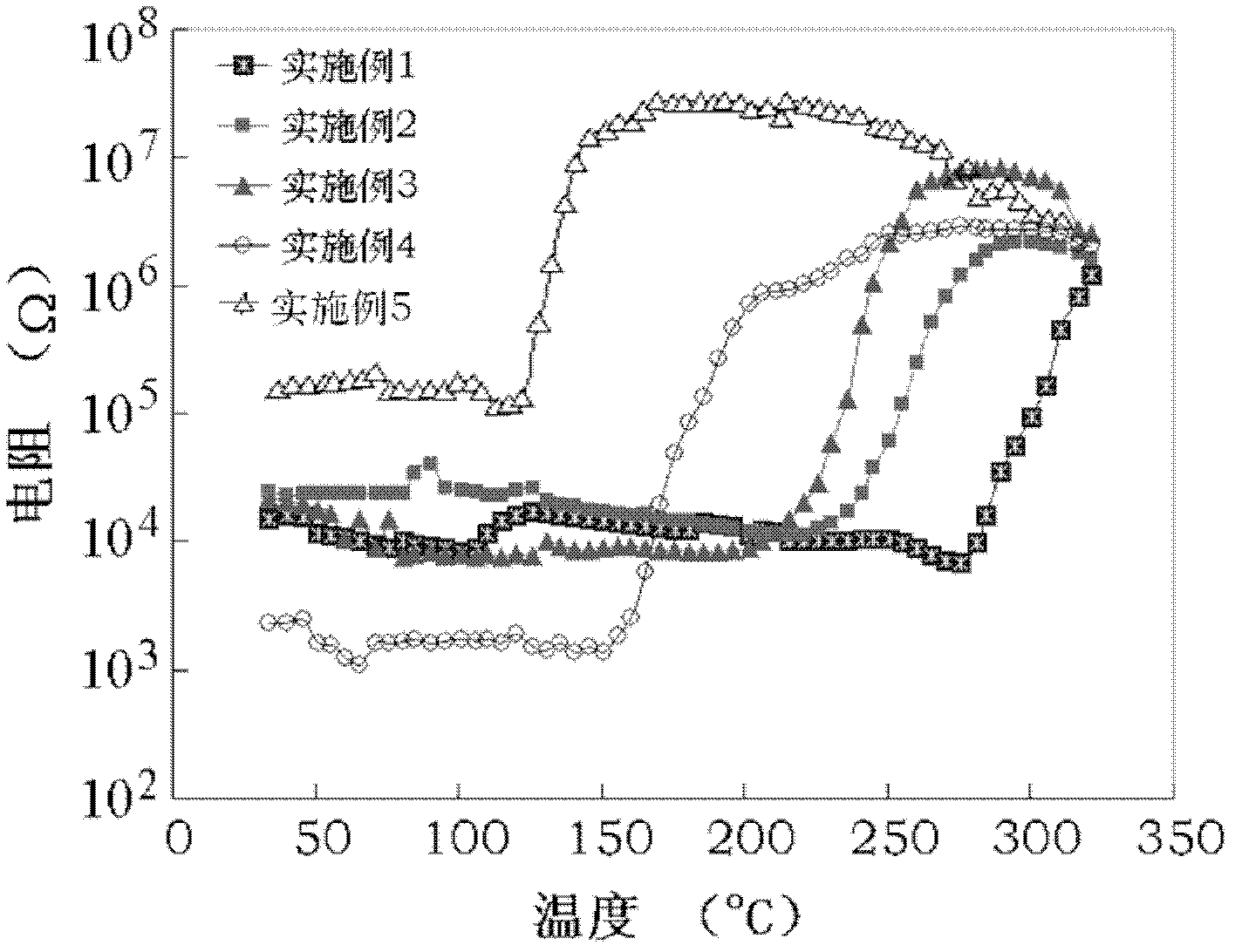

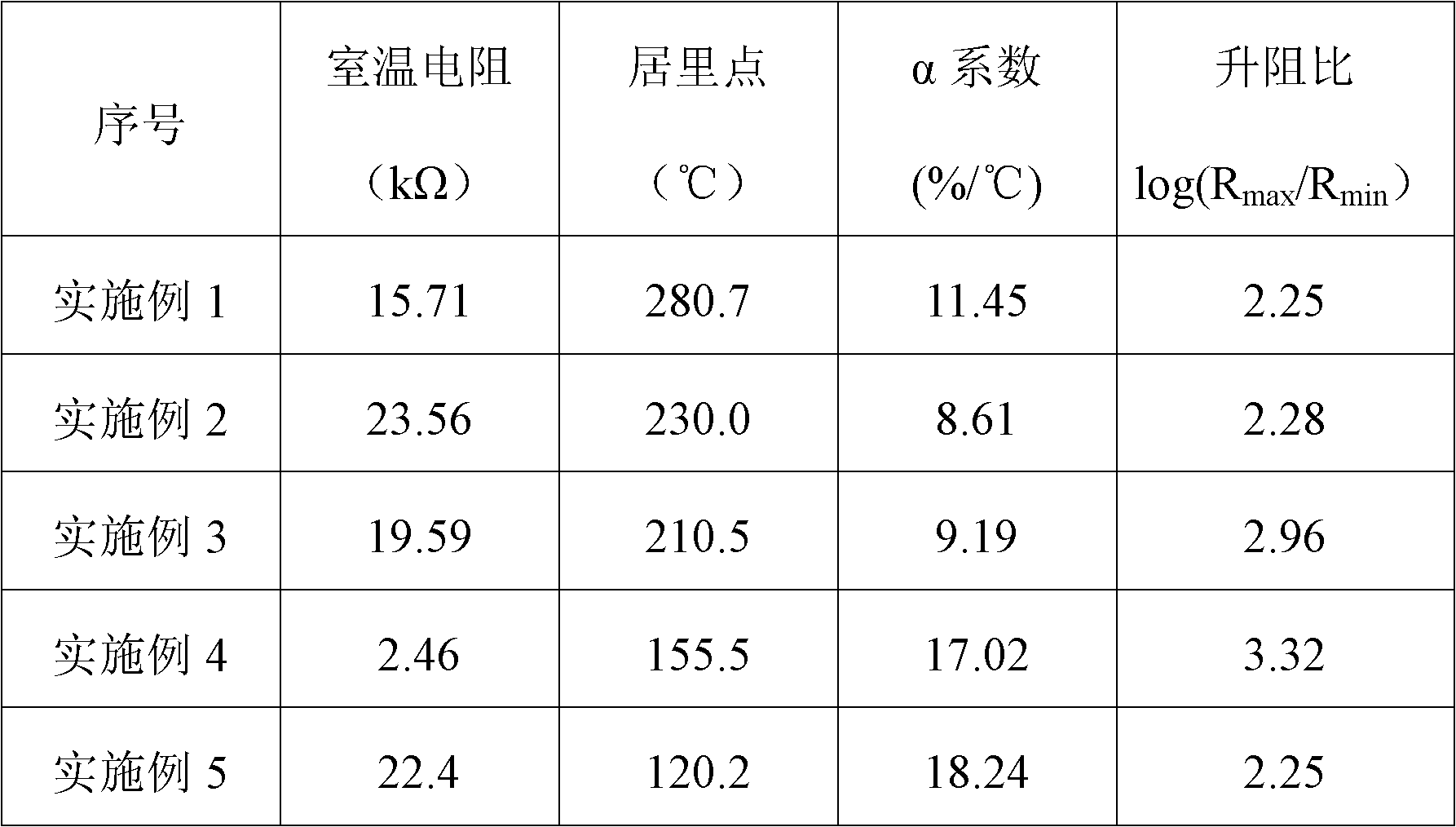

[0037] Prepared material properties are shown in Table 1 and figure 2 shown.

Embodiment 3

[0039] The present embodiment main component is by molecular formula (Bi 1-x / 2 K x / 2 )(Zn 1 / 2-x / 2 sn 1 / 2-x / 2 Ti x )O 3 The batching is carried out, wherein x=0.6; W is selected as the semiconducting element, which accounts for 0.1 mol% of the total molar amount of Zn, Sn and Ti. The initial raw material is selected from Bi 2 o 3 、K 2 CO 3 , ZnO, Sn, [CH 3 (CH 2 ) 3 O] 4 Ti, H 2 WO 4 . Material preparation is carried out according to the technological steps of following experiment:

[0040] ①Press the initial raw material according to (Bi 0.7 K 0.3 )(Zn 0.2 sn 0.2 Ti 0.6 )O 3 +0.001H 2 WO 4 Formula ingredients, weighing 28.844g Bi 2 o 3 , 3.635g K 2 CO 3 , 2.851g ZnO, 4.157gSn, 35.707g[CH 3 (CH 2 ) 3 O] 4 Ti and 0.046g H 2 WO 4 ;

[0041] ②The preparation process is the same as the steps ②~⑩ in Example 1.

[0042] Prepared material properties are shown in Table 1 and figure 2 shown.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Curie point | aaaaa | aaaaa |

| Curie point | aaaaa | aaaaa |

| Curie point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com