Plant polysaccharide and preparation method thereof as well as application of plant polysaccharide in cigarette

A technology of plant polysaccharides and cigarettes, applied in the preparation of tobacco, application, tobacco, etc., to achieve the effect of increasing the aroma, enhancing the sense of body fluid, and improving the brightness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

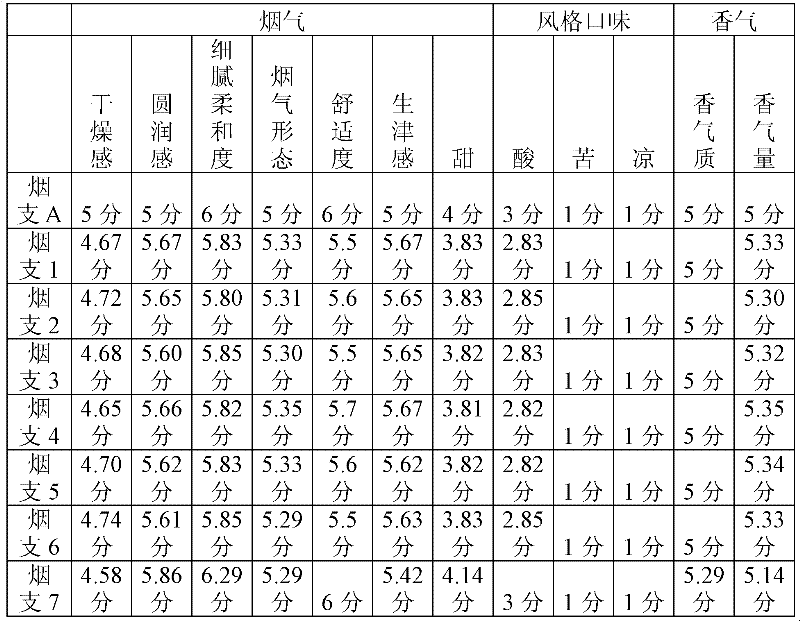

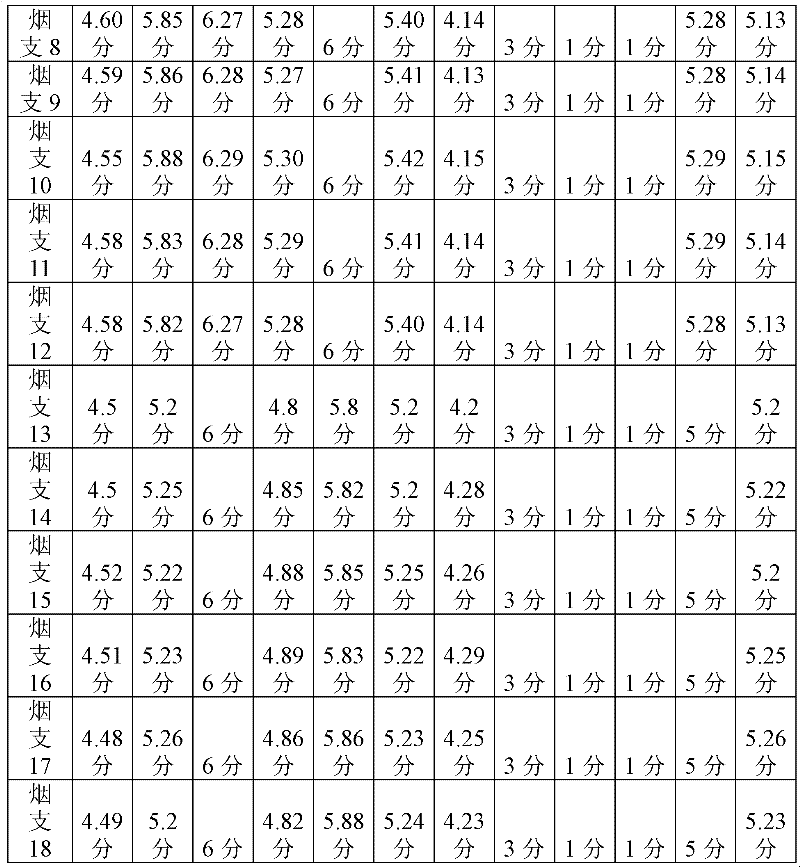

Examples

Embodiment 1

[0030] a. Wash the whole plant of Fenbei Schisandra and put it in an oven at 45°C to dry and pulverize it to 40 meshes to obtain Fenbei Schisandra powder;

[0031] b. Add Schisandra Fenbei powder to water 20 times the weight of Fenbei Schisandra powder, and reflux extraction at 100°C for 3 hours to obtain an extract;

[0032] c. After the extract is cooled, the filtrate is obtained after 10000r / min high-speed centrifugation and vacuum filtration, and the filtrate is concentrated in vacuum to 1 / 15 of the volume of the extract to obtain a concentrate;

[0033] d. Add ethanol with a volume fraction of 95% to the concentrated solution, so that the volume fraction of ethanol in the system reaches 85%, stir, let stand for 10 hours, centrifuge at 4000r / min for 15 minutes, collect the precipitate, and freeze-dry to obtain Schisandra chinensis polysaccharide .

[0034] According to 0.1‰ of the cut tobacco quality, weigh the Schisandra chinensis polysaccharide, make a solution of 0.4 m...

Embodiment 2

[0036] a. After washing the whole plant of Schisandra Fenbei, put it into an oven for drying at 40° C., take the dried sample and pulverize it to 60 mesh, and obtain Fenbei Schisandra powder;

[0037] b. Add Schisandra Fenbei powder to water 25 times the weight of Fenbei Schisandra powder, reflux and extract at 90°C for 4 hours to obtain an extract;

[0038] c. Cool the extract to room temperature, centrifuge at a high speed of 8000r / min for 15min, vacuum-filter the supernatant, and concentrate the filtrate in vacuum to 1 / 20 of the volume of the extract to obtain a concentrate;

[0039] d, add pure alcohol (i.e. ethanol with a volume fraction of 100%) to the concentrated solution, stir continuously, so that the volume fraction of ethanol in the system reaches 90%, leave it for 8h, centrifuge at 4000r / min for 15min, collect the precipitate, and freeze-dry it immediately Obtain Fenbei Schisandra (whole plant) crude polysaccharide.

[0040] Weigh the obtained Schisandra chinensi...

Embodiment 3

[0042] a. After washing the whole plant of Schisandra Fenbei, put it into an oven at 30°C, dry and pulverize it to 100 mesh, and obtain Fenbei Schisandra powder;

[0043] b. Add Schisandra Fenbei powder to water 50 times the weight of Fenbei Schisandra powder, reflux and extract at 70°C for 2 hours to obtain an extract;

[0044] c. After the extract is cooled, the filtrate is obtained after 10000r / min high-speed centrifugation and vacuum filtration, and the filtrate is concentrated in vacuum to 1 / 10 of the volume of the extract to obtain a concentrate;

[0045] d. Add ethanol with a volume fraction of 98% to the concentrated solution, so that the volume fraction of ethanol in the system reaches 75%, stir, let stand for 12 hours, centrifuge at 4000r / min for 15 minutes, collect the precipitate, freeze-dry to obtain the powdered back Schisandra polysaccharide .

[0046] According to 0.08‰ of the cut tobacco quality, weigh the Schisandra chinensis polysaccharide, make a solution ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com