A kind of road petroleum asphalt anti-aging agent and preparation method thereof

A technology of road petroleum asphalt and anti-aging agent, applied in the field of road petroleum asphalt, can solve the problems of low usage amount and insufficient anti-aging ability, and achieve the effect of reducing usage amount, solving the insufficient anti-aging ability, and being convenient to use.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0031] A road petroleum asphalt antiaging agent, comprising additive B and base soft component C, wherein the weight ratio of additive B is 15%, and the weight ratio of base soft component C is 85%; the weight ratio of said additive B Composition and weight ratio are:

[0032] Free Radical Scavenger 35%;

[0033] Peroxide decomposer 20%;

[0034] Light stabilizer 10%;

[0035] Metal ion complexing agent 35%.

[0036] The free radical scavenger is antioxidant 264; the peroxide decomposition agent is antioxidant DLTP; the light stabilizer is light stabilizer UV-770; the metal ion complexing agent is sodium xanthate.

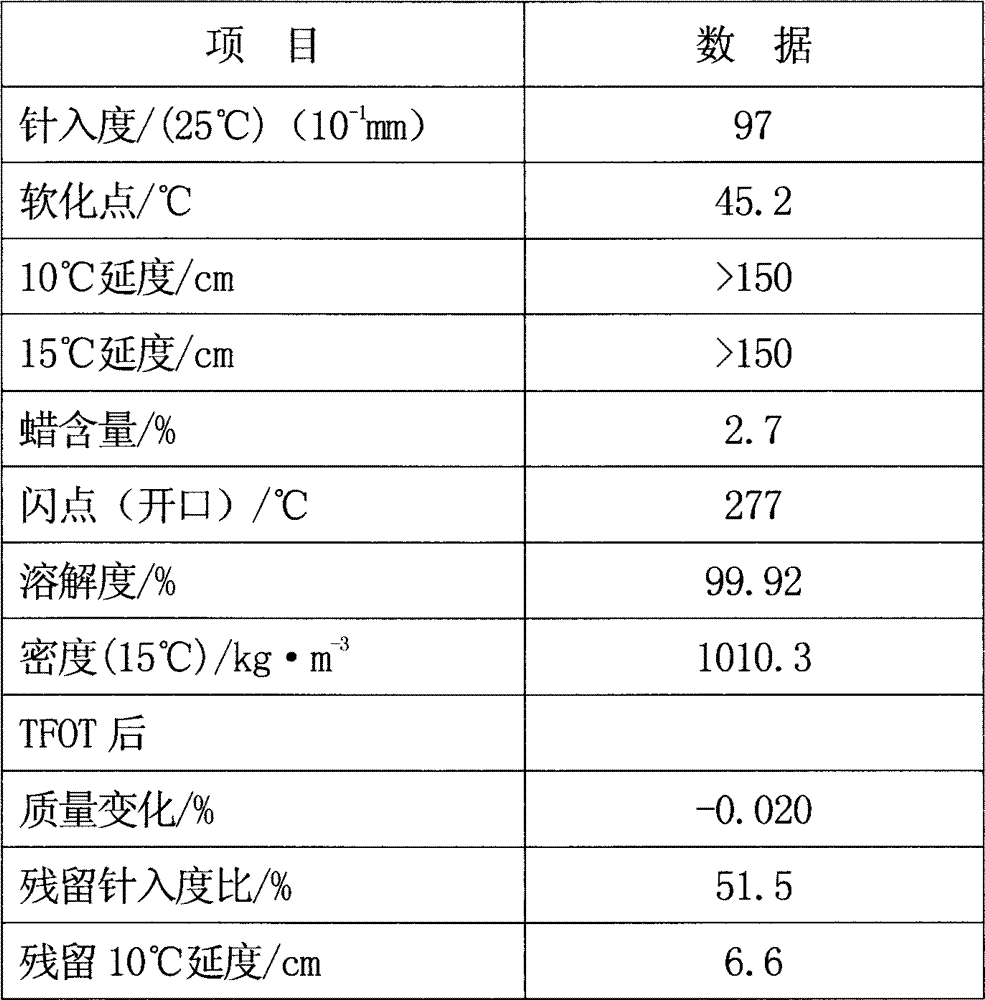

[0037] The performance indicators of the basic soft component C meet the figure 1 Road petroleum asphalt shown.

[0038] The preparation method is as follows: heat the basic soft component C to 150°C, add antioxidant 264, antioxidant DLTP, light stabilizer UV-770 and sodium xanthate respectively under stirring, and obtain road petroleum asphalt after stirring ...

Embodiment 2

[0040] A road petroleum asphalt antiaging agent, comprising additive B and base soft component C, wherein the weight ratio of additive B is 30%, and the weight ratio of base soft component C is 70%; the weight ratio of said additive B Composition and weight ratio are:

[0041] Free Radical Scavenger 40%;

[0042] Peroxide Decomposer 18%;

[0043] Light stabilizer 12%;

[0044] Metal ion complexing agent 30%.

[0045] The free radical scavenger is antioxidant 1010; the peroxide decomposition agent is antioxidant DSTP; the light stabilizer is light stabilizer GW-622; the metal ion complexing agent is sodium xanthate

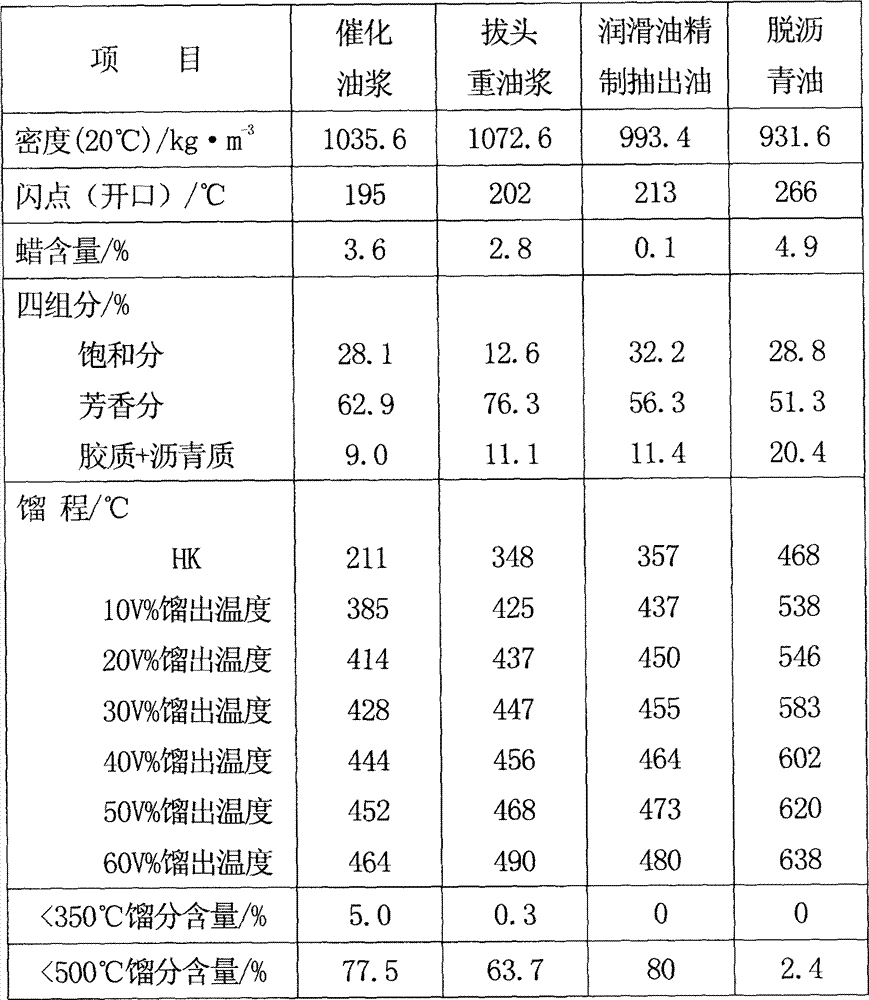

[0046] The basic soft component C is figure 2 Catalytic slurry shown.

[0047] The preparation method is as follows: heat the basic soft component C to 150°C, add antioxidant 1010, antioxidant DSTP, light stabilizer GW-622 and sodium xanthate under stirring, and mix well to obtain road petroleum asphalt anti-aging agent.

Embodiment 3

[0049] A road petroleum asphalt anti-aging agent, comprising additive B and base soft component C, wherein the weight ratio of additive B is 40%, and the weight ratio of base soft component C is 60%; the weight ratio of said additive B Composition and weight ratio are:

[0050] Free Radical Scavenger 45%;

[0051] Peroxide decomposer 20%;

[0052] Light stabilizer 13%;

[0053] Metal ion complexing agent 22%.

[0054] The free radical scavenger is antioxidant 1076; the peroxide decomposition agent is antioxidant DLTP; the light stabilizer is light stabilizer UV-770; the metal ion complexing agent is sodium xanthate.

[0055] The basic soft component C is that each performance index meets figure 2 Topping heavy oil slurry shown.

[0056] The preparation method is: heating the basic soft component C to 100°C, adding antioxidant 1076, antioxidant DLTP, light stabilizer UV-770 and sodium xanthate respectively under stirring, and stirring evenly to obtain road petroleum aspha...

PUM

| Property | Measurement | Unit |

|---|---|---|

| flash point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com