Permeability-based ultrasonic verification method of asphalt pavement preventative maintenance opportunity

A technology for preventive maintenance and asphalt pavement, applied in permeability/surface area analysis, using sound wave/ultrasonic wave/infrasonic wave to analyze solids, roads, etc. It can solve the problem that the timing of preventive maintenance of asphalt pavement does not give a quantitative standard for permeability, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0055] The present invention will be further described below in conjunction with the accompanying drawings and embodiments.

[0056] Taking the Xinhe-Xinzhuangzi section of Rongwu Expressway as an example, the method proposed by the present invention was adopted for the verification of the preventive maintenance timing of the SMA surface.

[0057] Through uniaxial compression and splitting tests, specimens with different types and sizes of damage were obtained. The SPT (Simple Performance Test) tester was used to test the dynamic modulus of the SMA asphalt mixture before and after damage; the ultrasonic wave velocity of the asphalt mixture before and after damage was tested by an ultrasonic tester; the ASTM non-directional water seepage The instrument tested the permeability coefficient of asphalt mixture before and after damage.

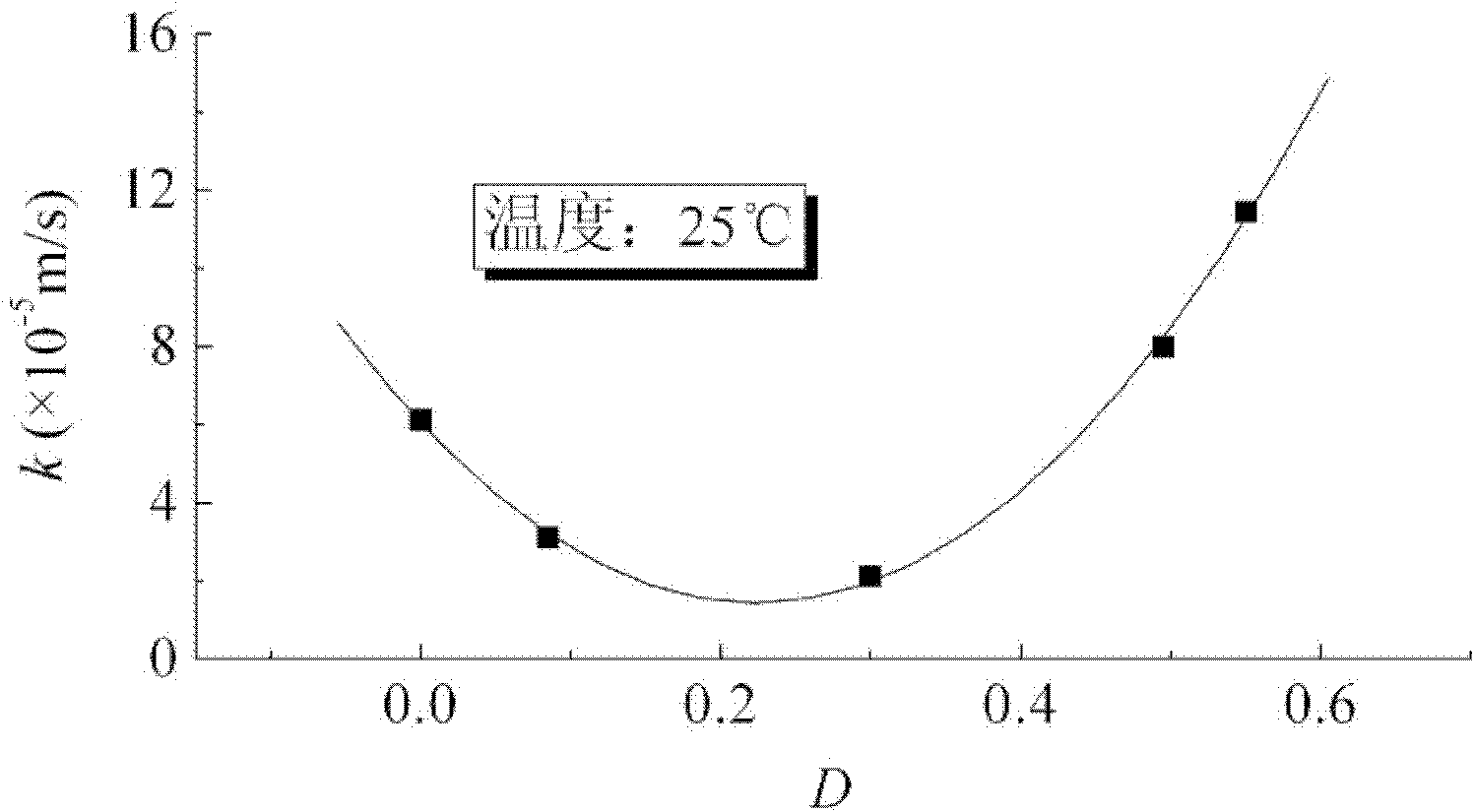

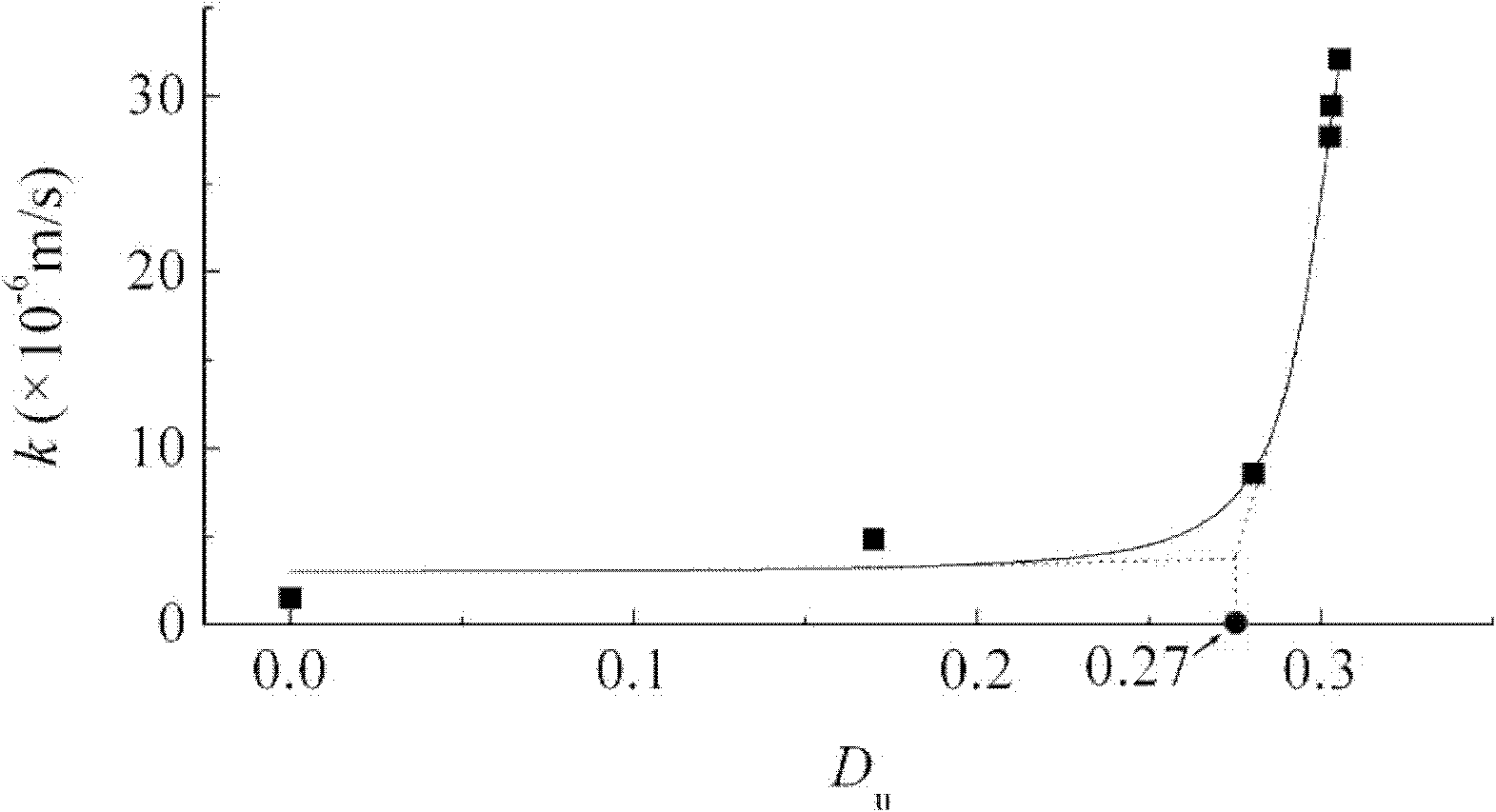

[0058] For the tested SMA asphalt mixture, it was found from the test that the damage factor D expressed by the dynamic modulus and the damage fac...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com