Method for densely building hydroelectric power station and hydroelectric power station capable of being densely built

A construction method and technology for power stations, applied in the direction of hydropower stations, hydropower, traditional hydropower energy, etc., can solve the problems of inability to build hydropower stations, rivers and rivers, etc. The effect of polluting the water source environment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

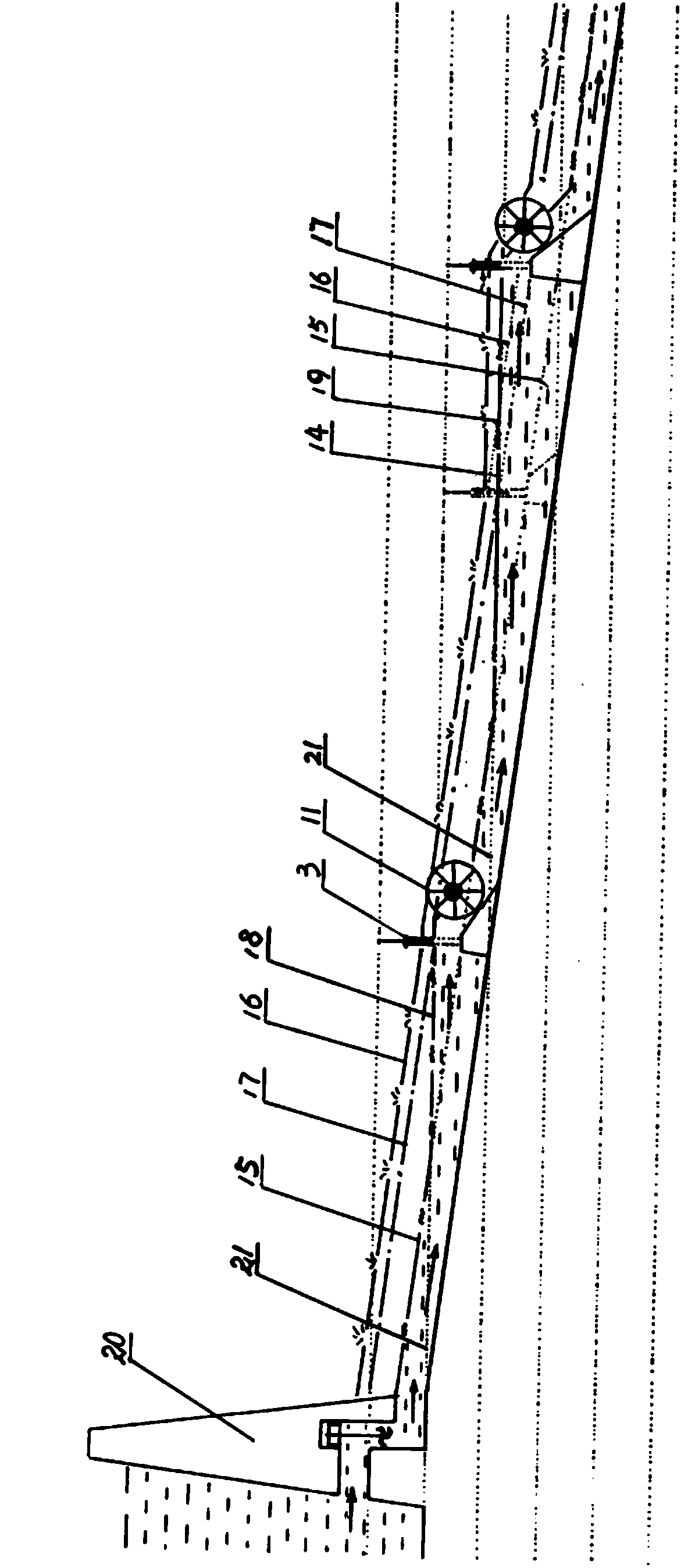

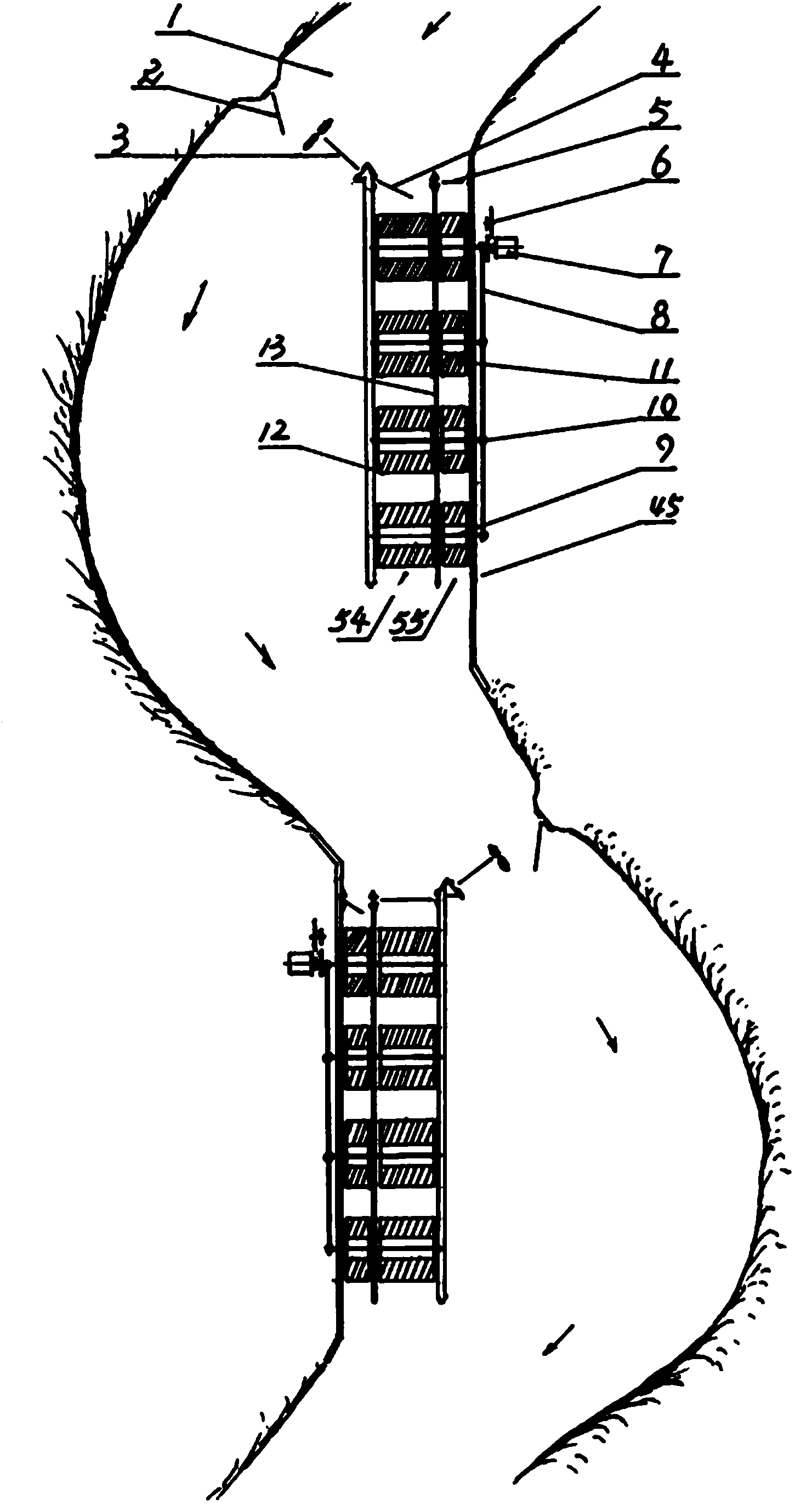

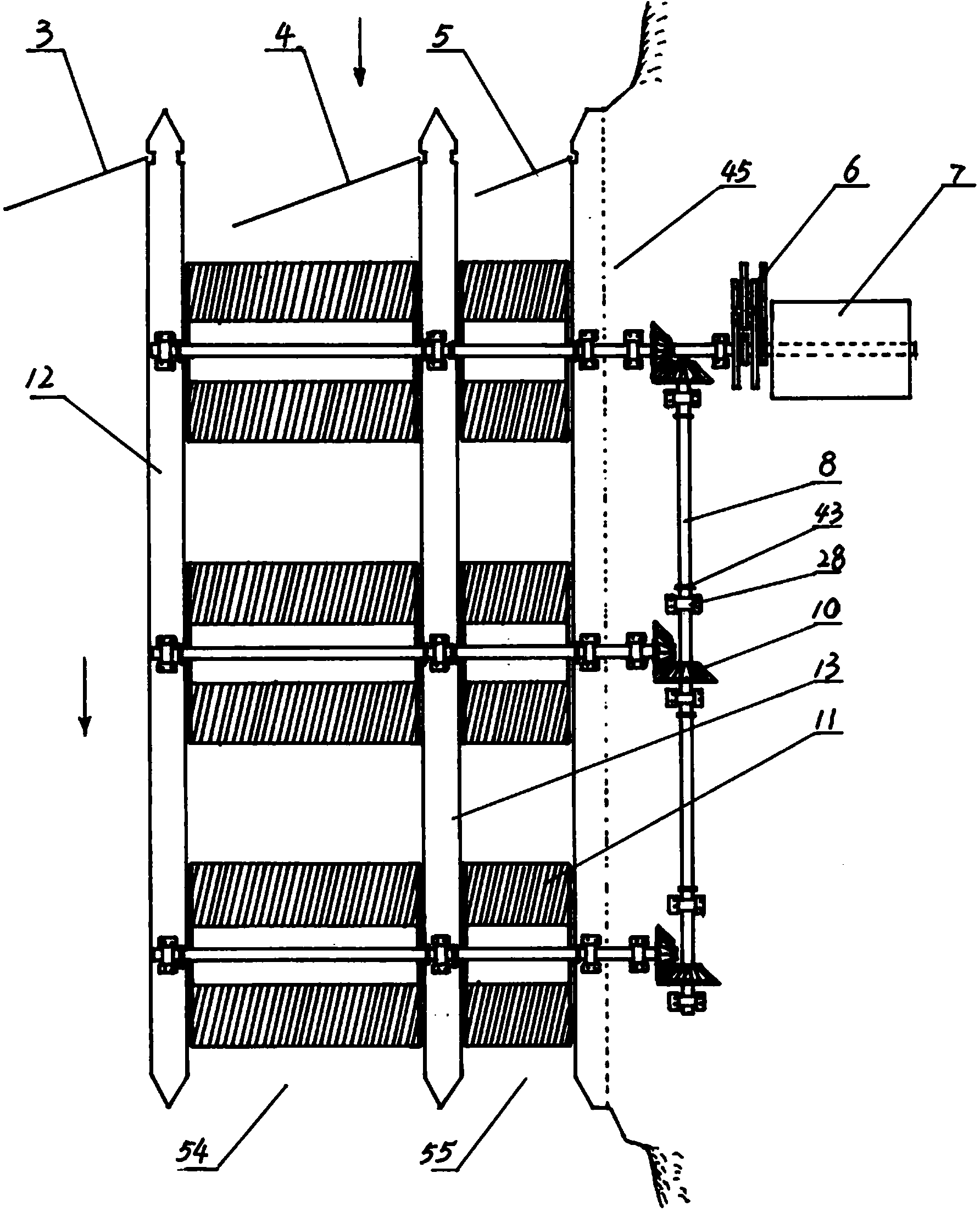

[0025] Embodiment 1: refer to figure 1 , figure 2 , image 3 , Figure 5 , Figure 8 , Figure 9 , a water conservancy power station, including a water turbine 11, a water turbine drive shaft 9, a reversing drive shaft 8, a speed change wheel set 6, and a generator set 7, it also includes first and second shunt gates 2, 3, first and second Two flush gates 5,4, river bank cement platform 45, first and second cement partition walls 13,12 and first and second water diversion channels 55,54 formed by the first and second cement partition walls 13,12 ; The first and second diversion gates 2,3 and the first and second flush gates 5 and 4 are successively built on the upstream end of the river or river 1 in the water direction, and the first and second diversion gates 2 and 3 Or the positions of the first and second flushing gates 5 and 4 can be located on the left or right bank of the river or river 1 according to specific terrain and needs, and they cover the entire width of...

Embodiment 2

[0027] Embodiment 2: refer to figure 1 , Figure 8 , Figure 10 , Figure 11 , Figure 12 , a water conservancy power station, comprising a water turbine 11, a water turbine drive shaft 9, a reversing drive shaft 8, a speed change wheel set 6, a generator set 7, a first shunt gate 2, the first, second, and third flush gates 5, 4, 57, the river bank cement platform 45, the first, second and third cement separation walls 13, 12, 58 and the first and second separation walls formed by the first, second and third cement separation walls 13, 12, 58 2. The third diversion trough 55, 54, 56; the first diversion gate 2 and the first, second and third flushing gates 5, 4, 57 are built on the upstream end of the river or river 1 in the water direction, the The position of the first diversion gate 2 or the first, second and third flushing gates 5, 4, 57 can be located on the left or right bank of the river or river 1 according to specific terrain and needs, and they cover the entire ...

Embodiment 3

[0028] Embodiment 3, with reference to Figure 10 , Based on Embodiment 2, the first diversion gate 2 described in Embodiment 2 forms a diversion tank 22, and the upstream and downstream sections of the diversion tank 22 are respectively equipped with upper and lower navigation gates 23,24. This embodiment is suitable for building in large and medium-sized river sections where ships navigate, and the original lift-type first diversion gate 2 is converted into sliding door-type upper and lower navigation gates 23, 24 for flood discharge and diversion during the flood season. It can also be used as a passage for ships when the river flow is normal.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com