Tubular pile defect processing method

A processing method and technology of pipe piles, applied to sheet pile walls, buildings, and foundation structure engineering, etc., can solve the problems of low construction cost, great impact on construction period and cost, and difficult construction, and achieve simple process, low cost, and easy construction. The effect of construction operations

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

[0019] The above solution will be further described below in conjunction with specific embodiments. It should be understood that these examples are used to illustrate the present invention and not to limit the scope of the present invention. The implementation conditions used in the examples can be further adjusted according to the conditions of specific manufacturers, and the implementation conditions not indicated are usually the conditions in routine experiments.

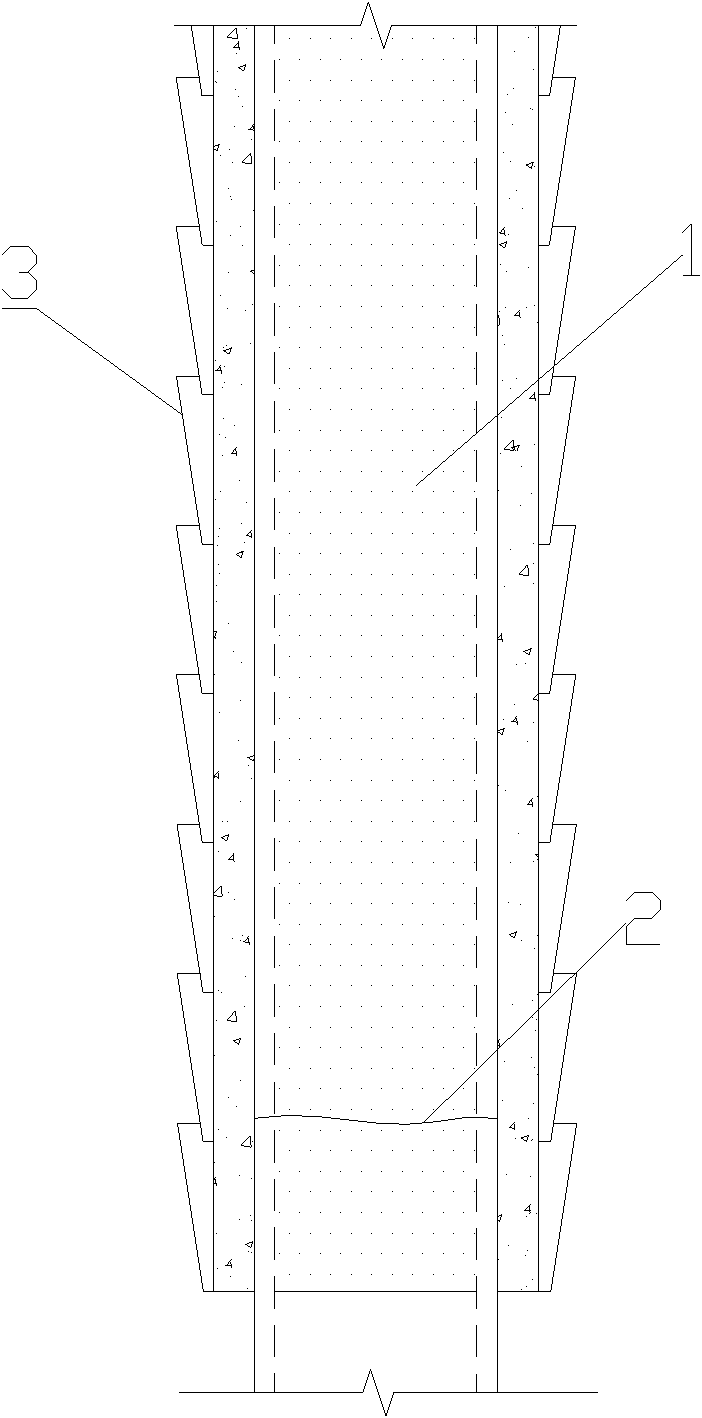

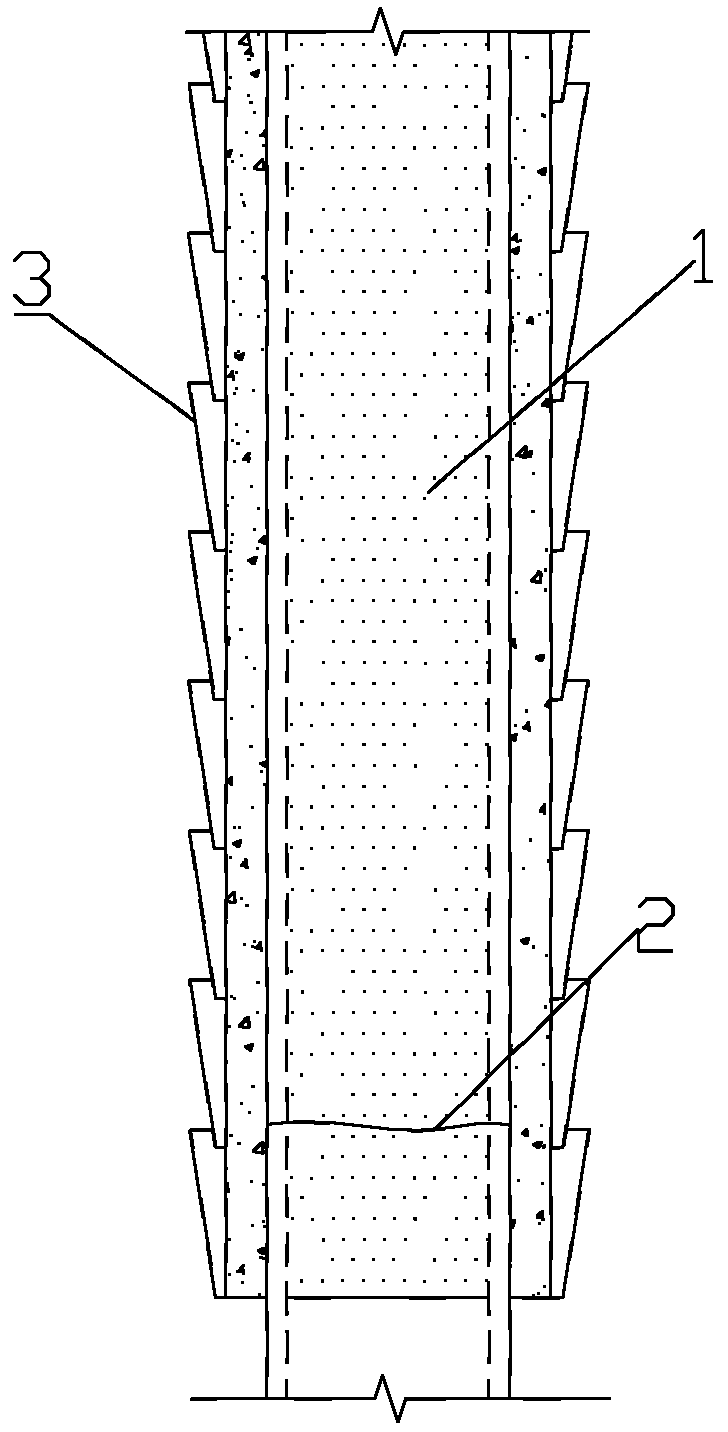

[0020] A treatment method for pipe pile defects, pipe pile 1 has relatively serious defects below 2m from the pile top,

[0021] Step 1, excavate the soil in the pipe pile 1 to a certain depth below the defect position 2;

[0022] Step 2: Reinforcing the pipe pile 1 with reinforced concrete core filling, the depth of the core filling is about 2m down from the defect position 2;

[0023] Step 3, the outer circle of the pipe pile 1 is supported by the casing 3, and the soil between the periphery of the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com