Dry-mixed mortar pneumatic-conveying stirring and spraying device

A technology of dry-mixed mortar and pneumatic conveying, which is applied in the direction of construction and building construction, which can solve the problems of troublesome cleaning, labor-intensive, dismantling and cleaning, etc., and achieve the advantages of convenient construction and transportation, improved worker arrangement, and improved use efficiency. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0029] Below in conjunction with accompanying drawing, the present invention will be further described:

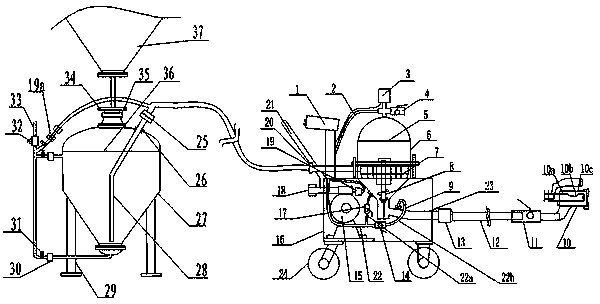

[0030] Such as figure 1 As described above, a dry-mixed mortar pneumatic conveying stirring spraying device includes a dry-mixed mortar pneumatic conveying bin pump connected to the outlet of the anti-segregation mortar bin 37, and a dry-mixed mortar pump connected to the outlet of the dry-mixed mortar pneumatic conveying bin pump. agitator sprayer,

[0031] As shown in the figure, the dry-mixed mortar mixing and spraying machine is used in conjunction with the anti-segregation mortar bin and the dry-mixed mortar pneumatic conveying bin pump. It includes a trolley 16 and a mixing tank 6 fixedly arranged on the trolley 16, a water pump 15 and The total controller 1 is used to control the feed amount, water intake and water pressure balance at the same time. There is a pressure difference regulator inside the total controller 1. The pressure difference regulator is connecte...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com