Cold damage prevention refrigeration house

A technology for preventing cold damage and cold storage, which is applied in coolers, refrigerated rooms, household refrigeration devices, etc. It can solve the problems of damaged item quality, uneven temperature field and velocity field, dry consumption of items, etc., to achieve safe operation and ensure uniformity sex, the effect of reducing the likelihood

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0016] The present invention will be described in detail below in conjunction with the accompanying drawings and specific embodiments.

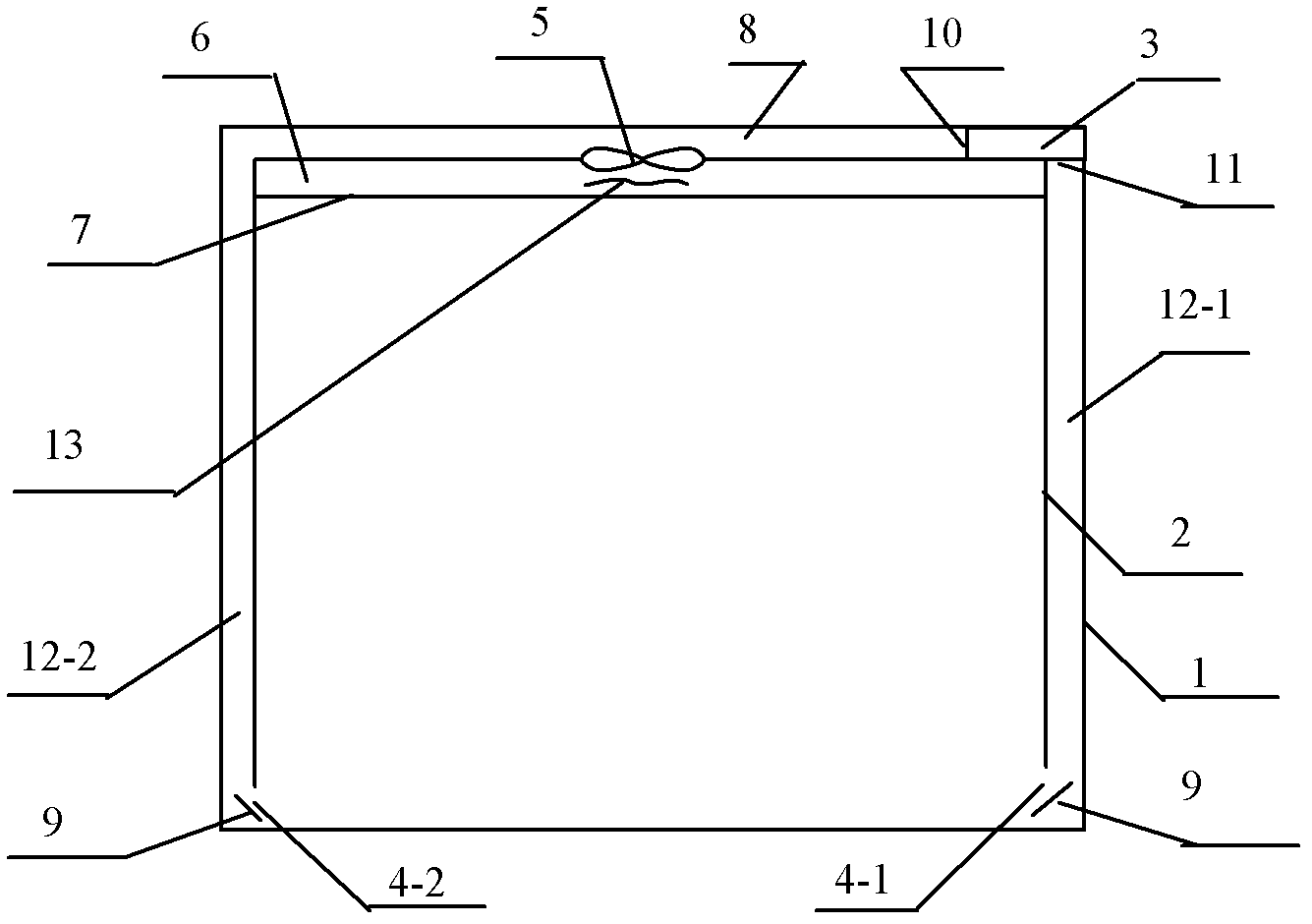

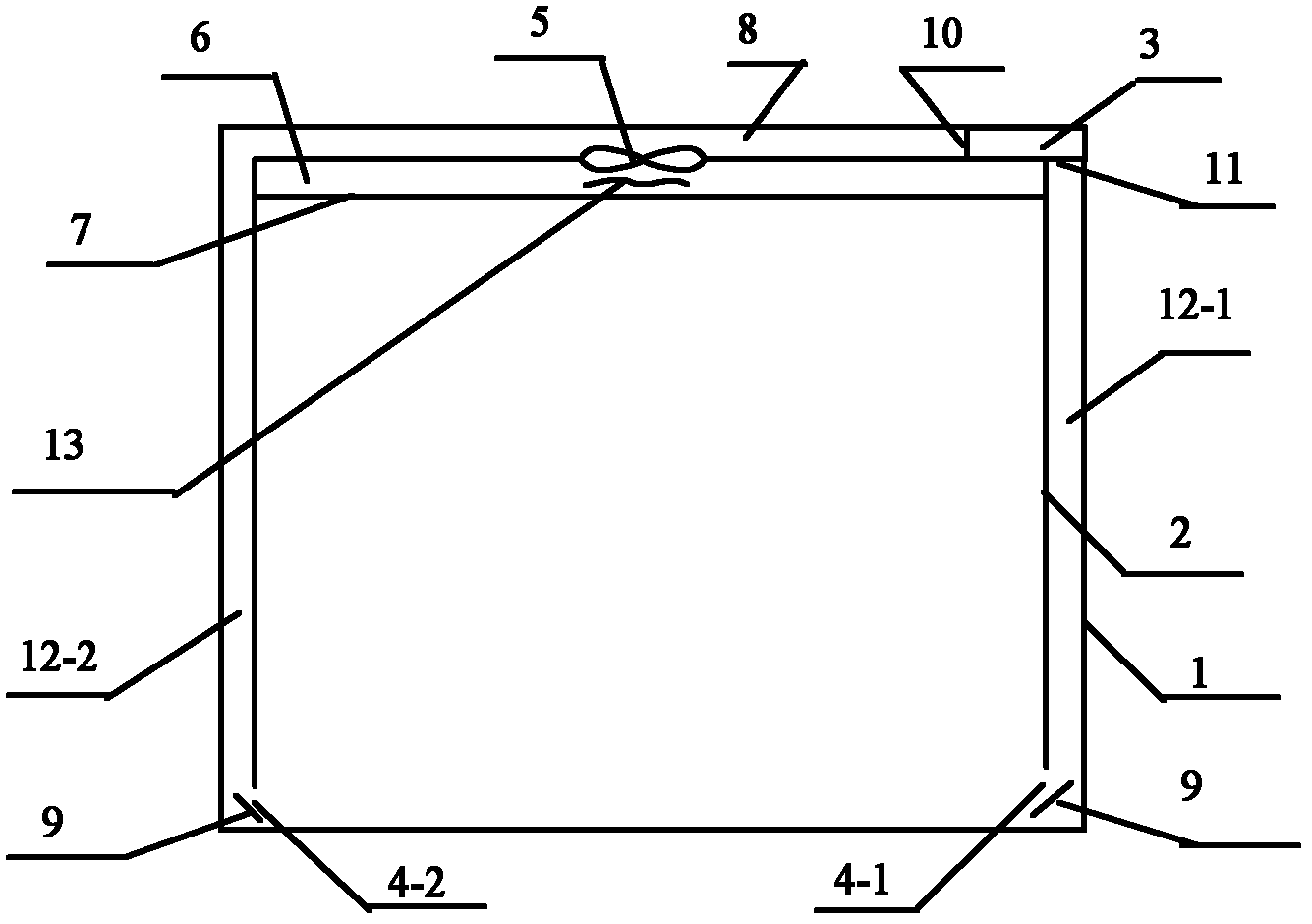

[0017] figure 1 It is a structural schematic diagram of the chilling injury prevention cold storage of the present invention, including a storage body 1 and an inner baffle 2, and return air jackets 12-1, 12-2 are formed between the storage body 1 and the inner baffle 2, and the inner baffle The upper end of the 2 is provided with an air supply plate 7, and the bottom of the inner baffle plate 2 is provided with a plurality of return air outlets 4-1, 4-2, and a partition is provided between the air supply plate 7 and the top of the storage body, so A mixing zone 8 is formed between the dividing plate and the top of the storage body, a static pressure air supply zone 6 is formed between the dividing plate and the air supply plate, an air supply fan 5 is installed in the middle of the dividing plate, and the mixing zone 8 A cooling fan 3 is in...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com