Width measurement mechanism

A width measurement and measuring rod technology, applied in the direction of measuring device, mechanical measuring device, using mechanical device, etc., can solve the problems of inaccurate measurement data, complicated operation, unsuitable for mass production of workpieces, etc., to achieve high measurement accuracy and simple operation. , the effect of simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0013] The present invention will be further described below in conjunction with specific drawings and embodiments.

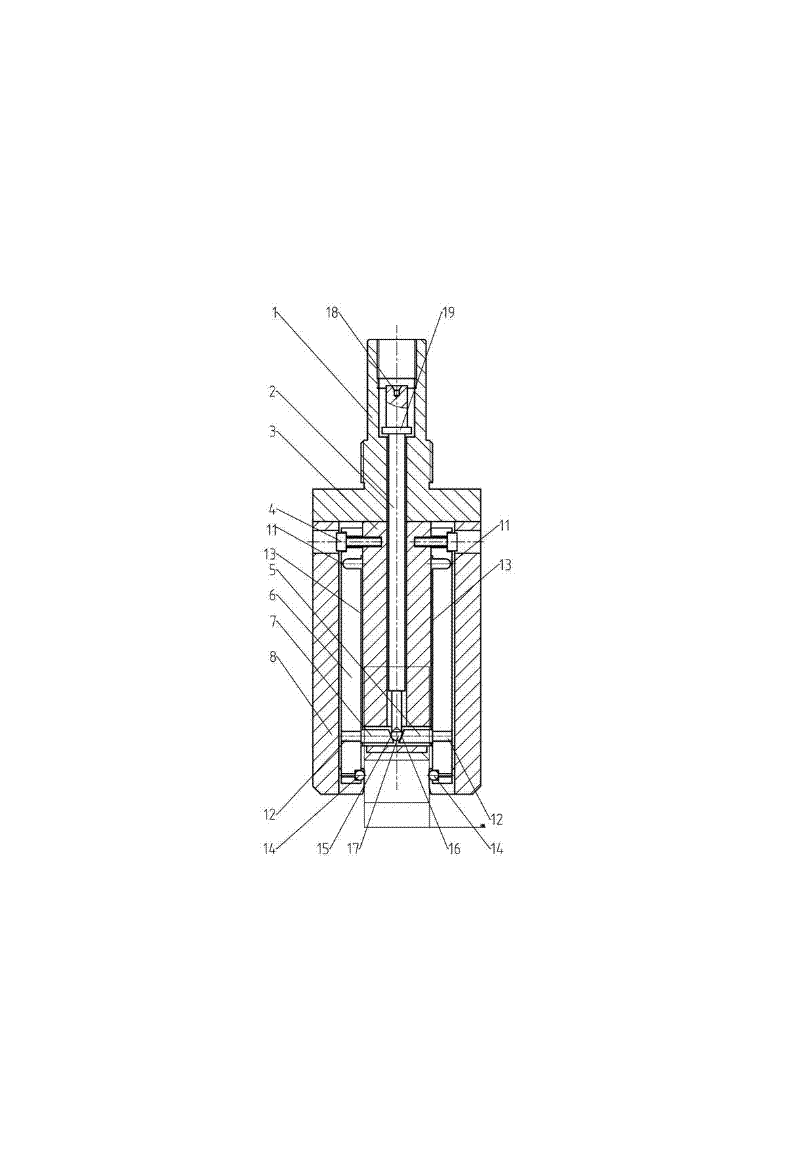

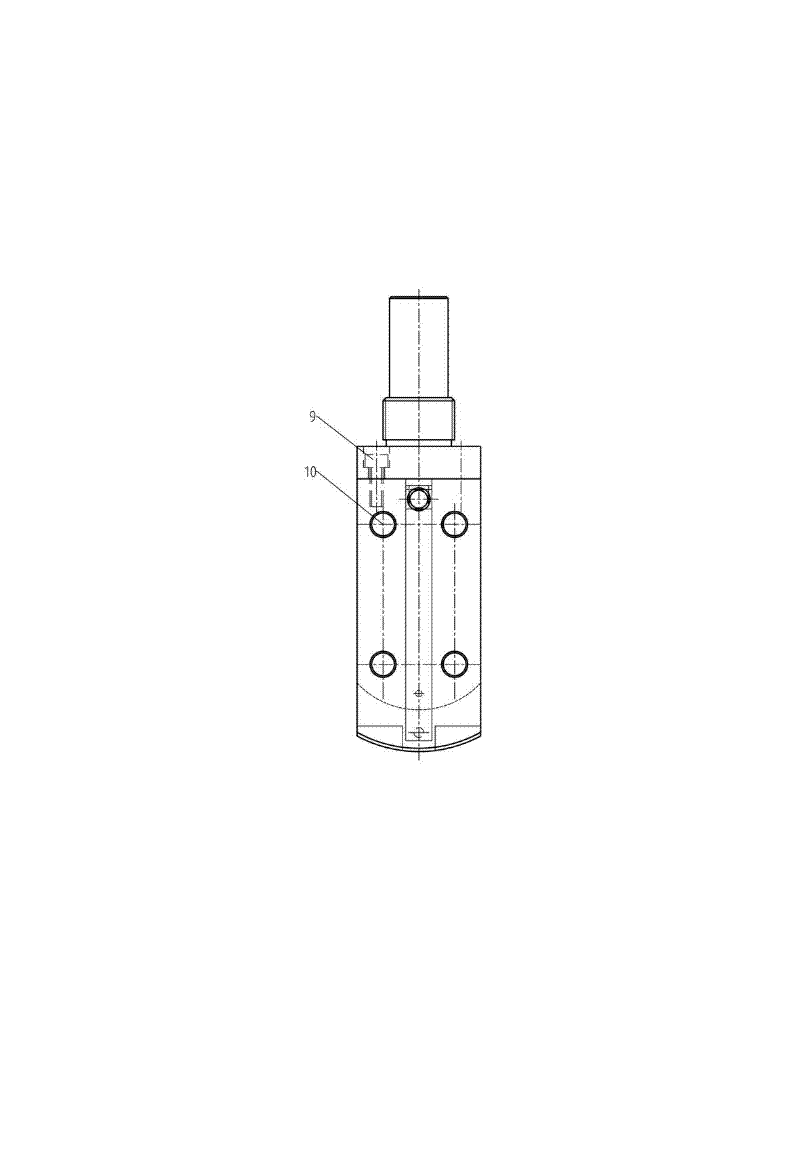

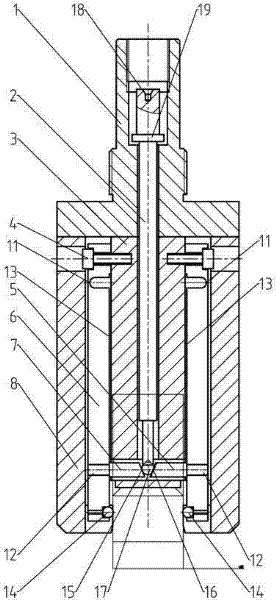

[0014] Such as figure 1 As shown: the present invention is mainly composed of flange 1, ejector rod 2, gauge body 3, screw 4, first measuring rod 5, elastic block 6, second measuring rod 7, limit block 8, screw 9, screw 10, etc. .

[0015] Width measuring mechanism, which includes installation grooves 13 provided on both sides of the gauge body 3, two elastic blocks 6 are connected with screws 4 in the installation grooves 13, elastic deformation regions 11 and bonded measuring balls 14 are provided on the elastic blocks 6, And the installation hole 12 is opened on the elastic block 6, and the first measuring rod 5 and the second measuring rod 7 are respectively installed in the mounting hole 12. The other end of the first measuring rod 5 is provided with an oblique groove 16, and the second measuring rod 7 is separately One end is provided with a bevel 15 . ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com