Three-degree-of-freedom integrated stick-slip linear positioning device

A positioning device, stick-slip technology, applied in the direction of measuring devices, instruments, nanotechnology, etc., can solve the problems of large volume, low positioning accuracy, large assembly error, etc., to achieve small volume, high positioning accuracy, large output force Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

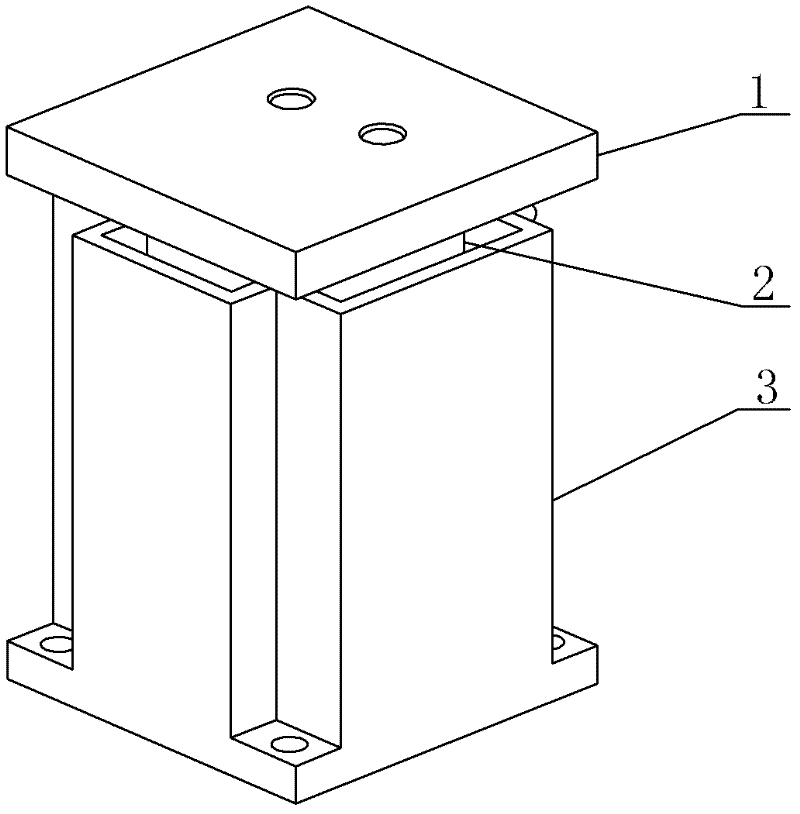

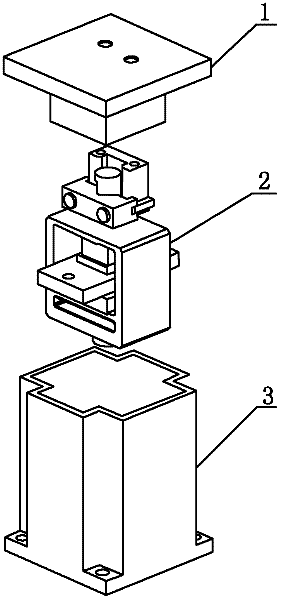

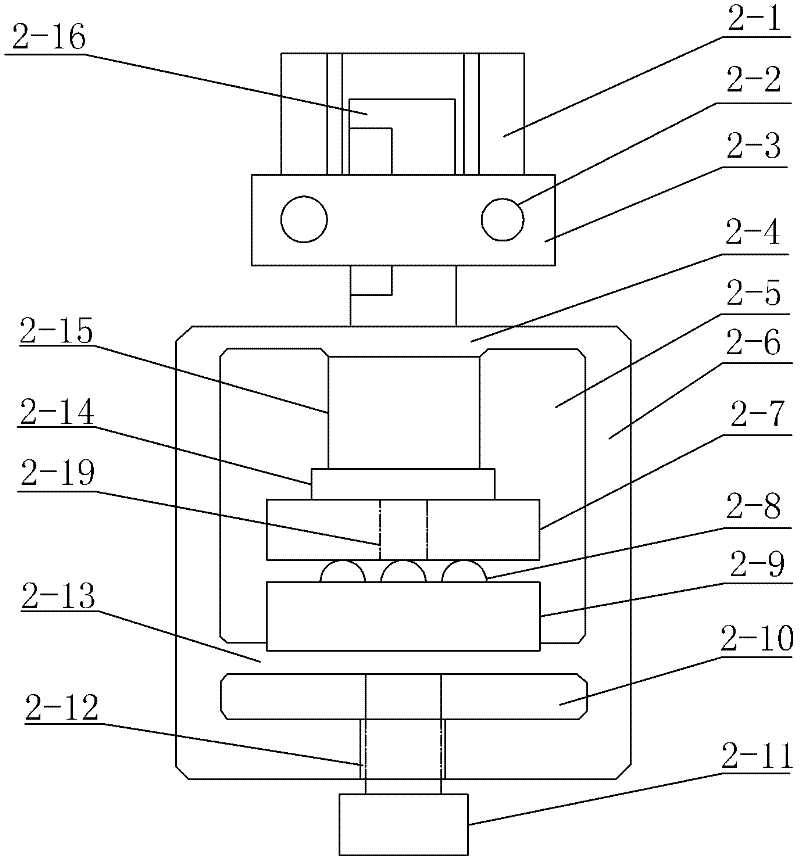

[0009] Specific implementation mode one: combine Figure 1 to Figure 9 Describe this embodiment. The three-degree-of-freedom integrated stick-slip linear positioning device of this embodiment includes a bearing cover 1, a drive unit 2 and a base 3. The bearing cover 1 includes a bearing plate 1-1 and a drive unit 2 The matching cover 1-2, the cover 1-2 is fixed on the plate surface of the bearing plate 1-1, and the drive unit 2 includes a first pressing block 2-2, a second pressing block 2-1, Elastic driving seat 2-6, piezoelectric ceramic driver 2-15, guide column 2-16, contact foot 2-14, displacement plate 2-7, pre-tightening pressure plate 2-9 and a plurality of balls 2-8, described The elastic drive seat 2-6 is a drive seat with a square cavity 2-5, and the first briquetting block 2-2 and the second briquetting block 2-1 are all arranged on the upper elastic plate 2-4 of the elastic drive seat 2-6 Above, the guide post 2-16 is clamped between the second press block 2-1 an...

specific Embodiment approach 2

[0010] Specific implementation mode two: combination image 3 To illustrate this embodiment, the shape of the tentacles 2-14 described in this embodiment is flat or hemispherical. Such setting meets the design requirements. Others are the same as in the first embodiment.

specific Embodiment approach 3

[0011] Specific implementation mode three: combination Figure 5 To illustrate this embodiment, the number of blind holes 2-18 described in this embodiment is four, and the four blind holes 2-18 are arranged in a cross shape on the upper end surface of the pre-tightening platen 2-9, and the four blind holes The sides of the quadrilateral formed by the centers of 2-18 are equal. Such setting effectively reduces the frictional force when the displacement plate moves and meets the design requirements. Others are the same as in the first or second embodiment.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com