Method for diagnosing fault of automatic ammunition supply and transportation device

A technology for fault diagnosis and ammunition supply and delivery. It is applied in the direction of measuring devices, ammunition supply, and weapon accessories. It can solve problems such as stuck and stopped shooting, poor movement, etc., and achieve the effect of improving time-frequency resolution.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

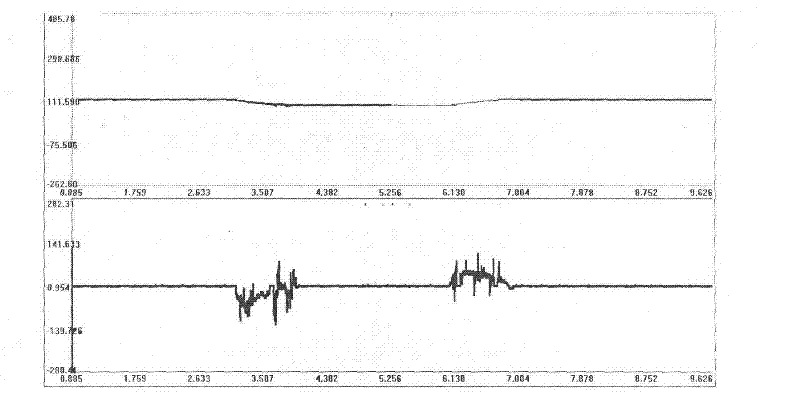

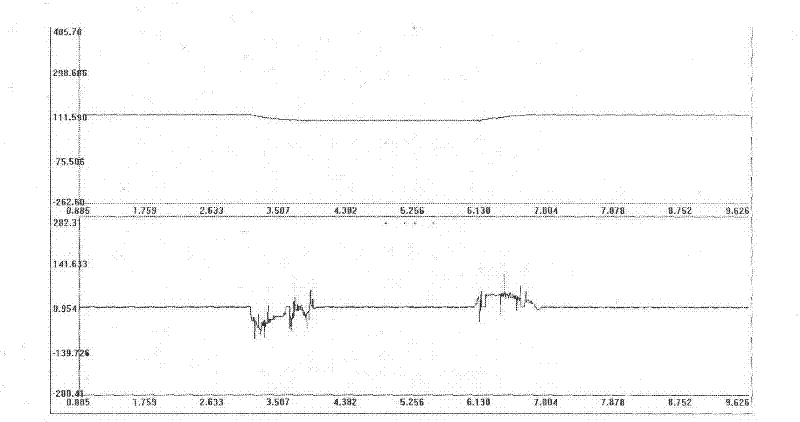

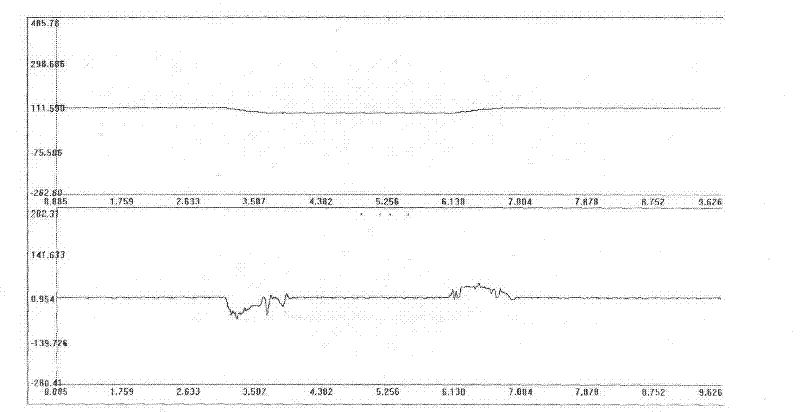

[0025] Based on the current analysis theory and the mechanism motion cycle diagram of the automatic bomb feeding device (reference Picture 11 ), to measure the current of the pusher and the angle, angular velocity, and angular acceleration of the ammunition (munition) coordination arm during the action of the automatic ammunition supply and transport device, and analyze and process various data. Use appropriate time domain and frequency domain analysis and processing methods, such as Information entropy, wavelet packet decomposition, etc., extracting various time domain and frequency domain features, combined with the diagnosis method with expert rules, can separate the action state of the automatic bomb feeding device and predict the failure. Wavelet packet decomposition can also be used to extract energy and information entropy characteristics of multiple frequency bands for motion and shock response signals, and then use the proportional gradient conjugate momentum algorithm ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com