Device and method for testing reliability of chain-type tool magazine and manipulator

A chain-type tool magazine and testing device technology, which is applied to measuring devices, testing of machine/structural components, instruments, etc., can solve problems such as difficulty in determining, no tool-changing process parameter detection system, and inaccurate results. The effect of market prospect, simple structure and convenient operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

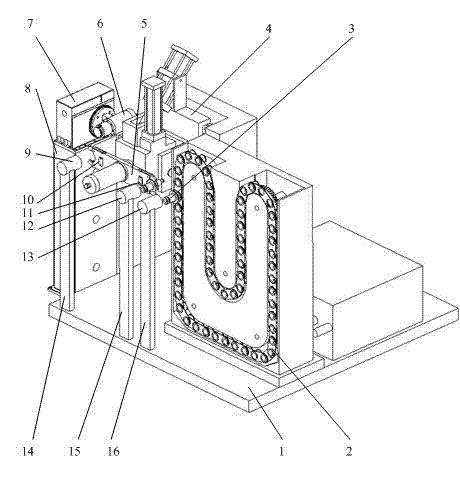

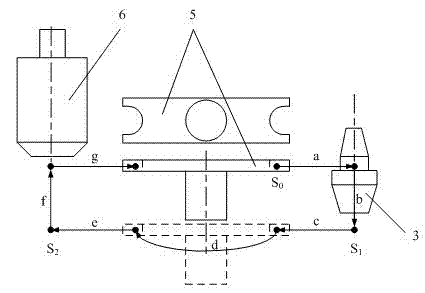

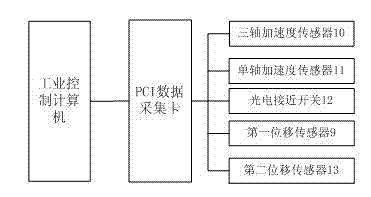

[0011] combine figure 1 , the reliability test device of the chain tool magazine and the manipulator of the present invention includes a base 1, a chain knife magazine 2, a tool 3, a hydraulic drive mechanism 4, a manipulator 5, a main shaft 6, a fixed frame 7, a test bench 8, a first displacement Sensor 9, triaxial acceleration sensor 10, uniaxial acceleration sensor 11, photoelectric proximity switch 12, second displacement sensor 13, first support frame 14, second support frame 15 and third support frame 16, wherein base 1 is fixed on the ground Above, the chain tool magazine 2 is fixedly installed on the base 1, the tool 3 is set on the tool position of the chain tool magazine 2 and is rotated by the chain tool magazine 2 to reach the tool changing position, and the hydraulic drive mechanism 4 belongs to the chain tool magazine and a part of the whole product of the manipulator and is fixedly connected with the chain tool magazine 2, the whole chain tool magazine and the m...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com