Method for measuring effective diffusion coefficient and porosity of porous medium

A technology of diffusion coefficient and porous medium, applied in the field of testing, can solve the problems of toxicity of test gas, cumbersome measurement, difficult to measure quickly and accurately, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

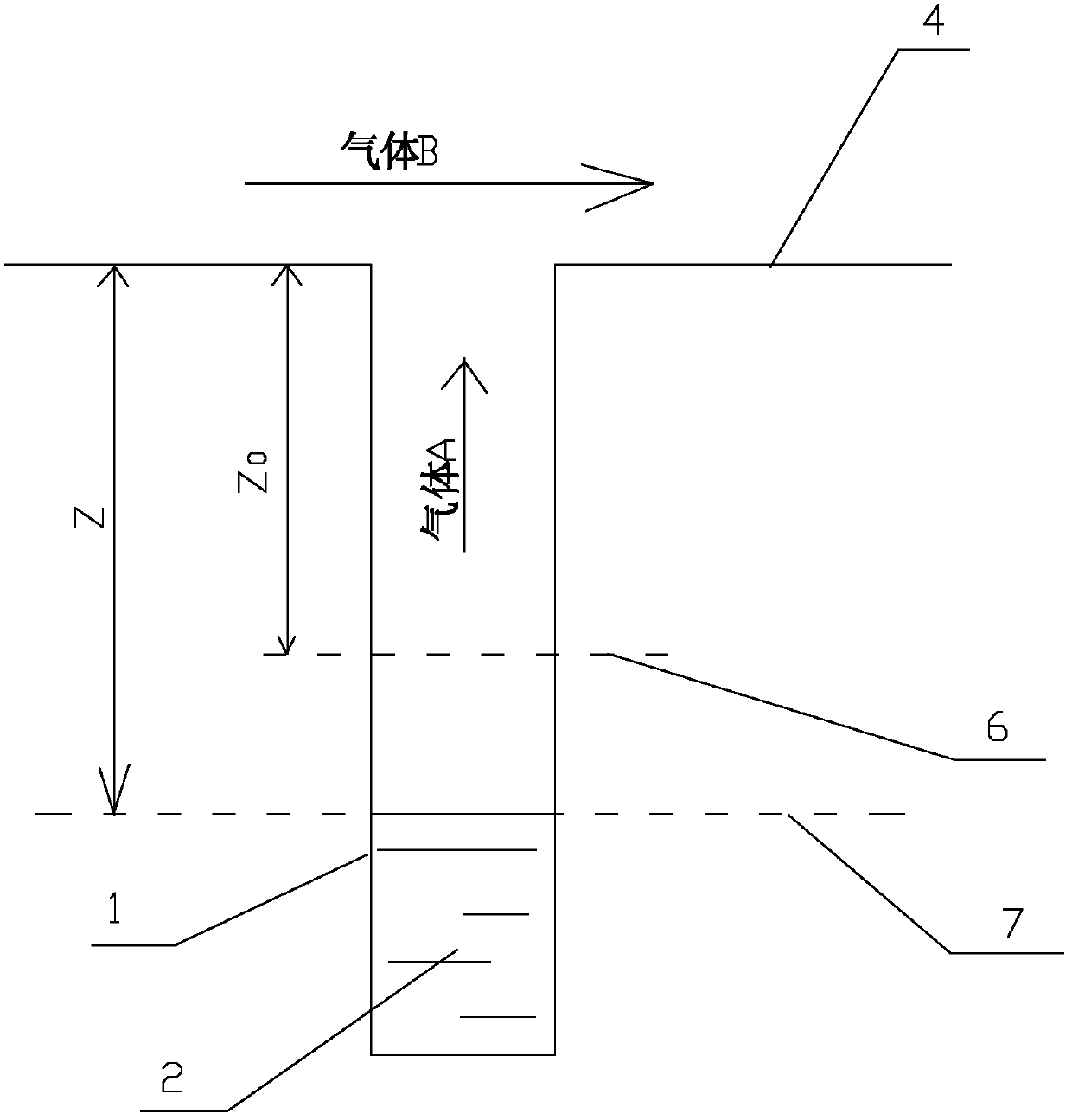

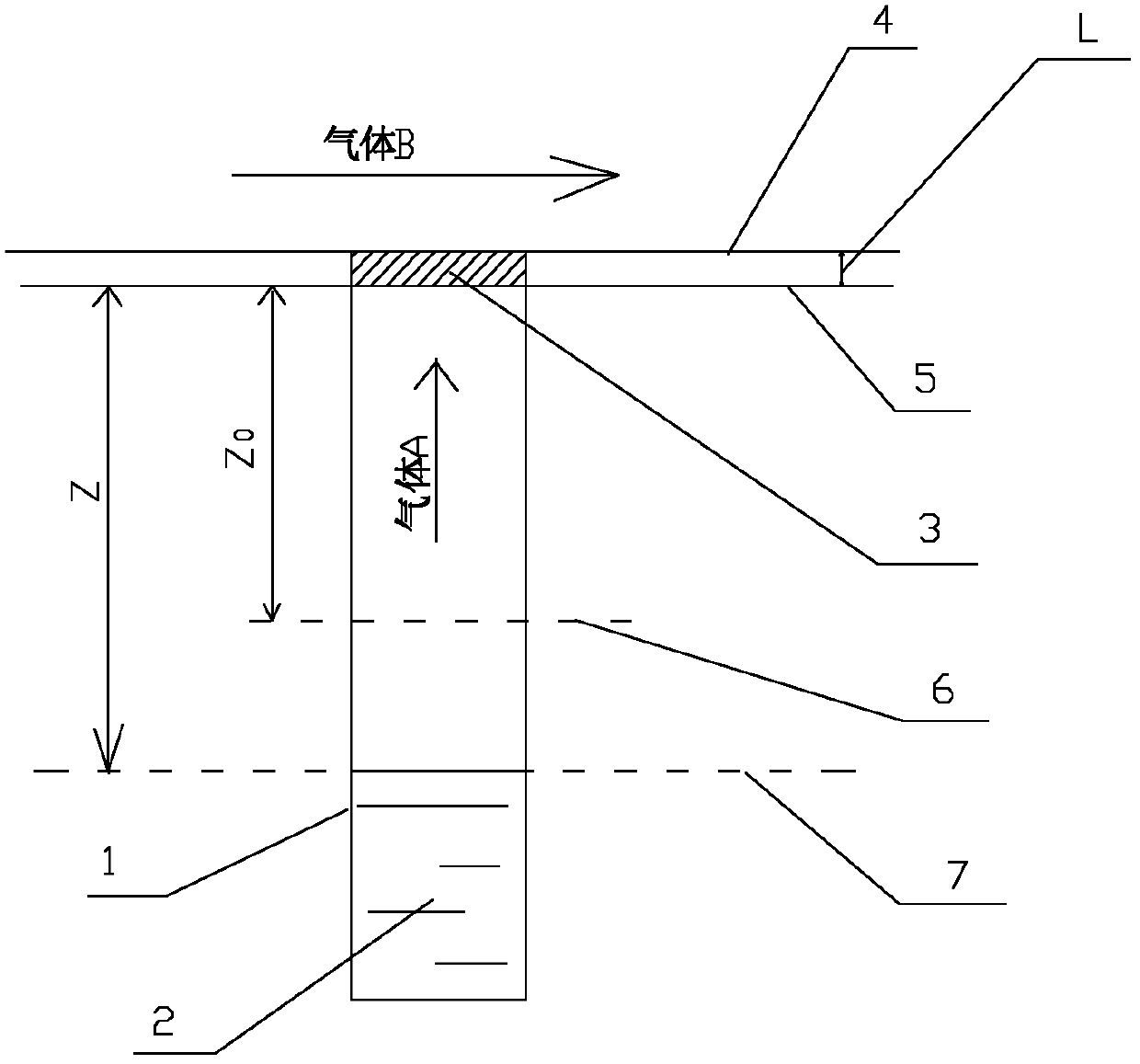

Method used

Image

Examples

Embodiment 1

[0084] The liquid with ethanol as component A and air as component B, first measure the diffusion coefficient D of ethanol vapor in air AB , and then measure the effective diffusion coefficient D of ethanol vapor in the porous carbon paper ABP .

[0085] D ABP = ρ AL RTl p BM , p M A θ · z - z 0 p AX - p A 2

[0086] Determination of effective diffusion coefficient D of ethanol vapor in porous carbon paper ABP ...

Embodiment 2

[0137] Taking water as component A of liquid and component B as air, first measure the diffusion coefficient D of water vapor in air under different conditions AB , and then measure the effective diffusion coefficient D of water vapor in the porous carbon paper ABP .

[0138] Determination of effective diffusion coefficient D of water vapor in porous carbon paper ABP The parameters of are as follows:

[0139] R——gas constant, 8.314×10 3 N m / (kmol K);

[0140] m A - the molar mass of component A (water), 18.09kg / kmol;

[0141] θ——component A (water) liquid level in the evaporation tube by z 0 The time taken to drop to z, 18000s;

[0142] l—thickness of the porous membrane, m;

[0143] T - thermodynamic temperature, respectively 310K, 315K, 320K, 325K, 330K;

[0144] p AX ——Partial pressure of component A (water) under different conditions (calculated from formula (7)), Pa;

[0145] ρ AL ——Density of component A (water) at different temperatures, kg / m 3 ;

[0146] ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com