Fly-simulation visual online detection device and method for surface defects

A detection method and detection device technology, applied in the direction of optical testing flaws/defects, image data processing, instruments, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0062] The present invention will be described in further detail below in conjunction with the accompanying drawings.

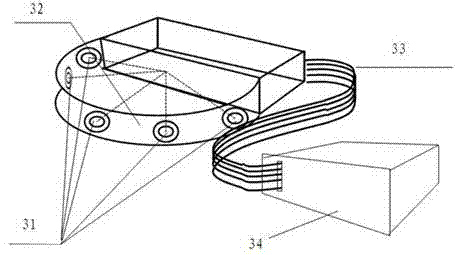

[0063] Such as figure 1 As shown, the fan imitation fly vision online surface defect detection device includes a CCD image sensor part and an embedded image processing unit; wherein, the sensor structure part adopts a multi-CCD image sensor 31 combination device that is arranged in a fan-shaped axis at the same point, and the multi-CCD The image sensors 31 are distributed on a semicircular mounting board 32 , and the signal lines of the multi-CCD image sensors 31 are connected to the embedded image processing unit 34 through the video coaxial cable 33 .

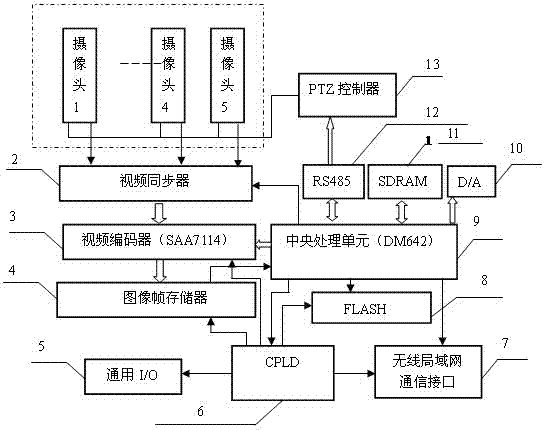

[0064] Such as figure 2 Shown is that the embedded image processing unit of the present invention is with DSP core, is characterized in that video synchronizer [2], is used for coordinating the input of three camera cooperative work and control video signal; Video coder [3], is used for analog video Digit...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com