Clamping device for alignment of optical axis of compound wave plate

A clamping device and composite wave plate technology, applied in the direction of installation, optics, optical components, etc., can solve the problem of no wave plate clamping and its motion control.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] The structure and function of the clamping device for aligning the optical axis of the composite wave plate provided by the present invention will be further described in detail below in conjunction with the accompanying drawings:

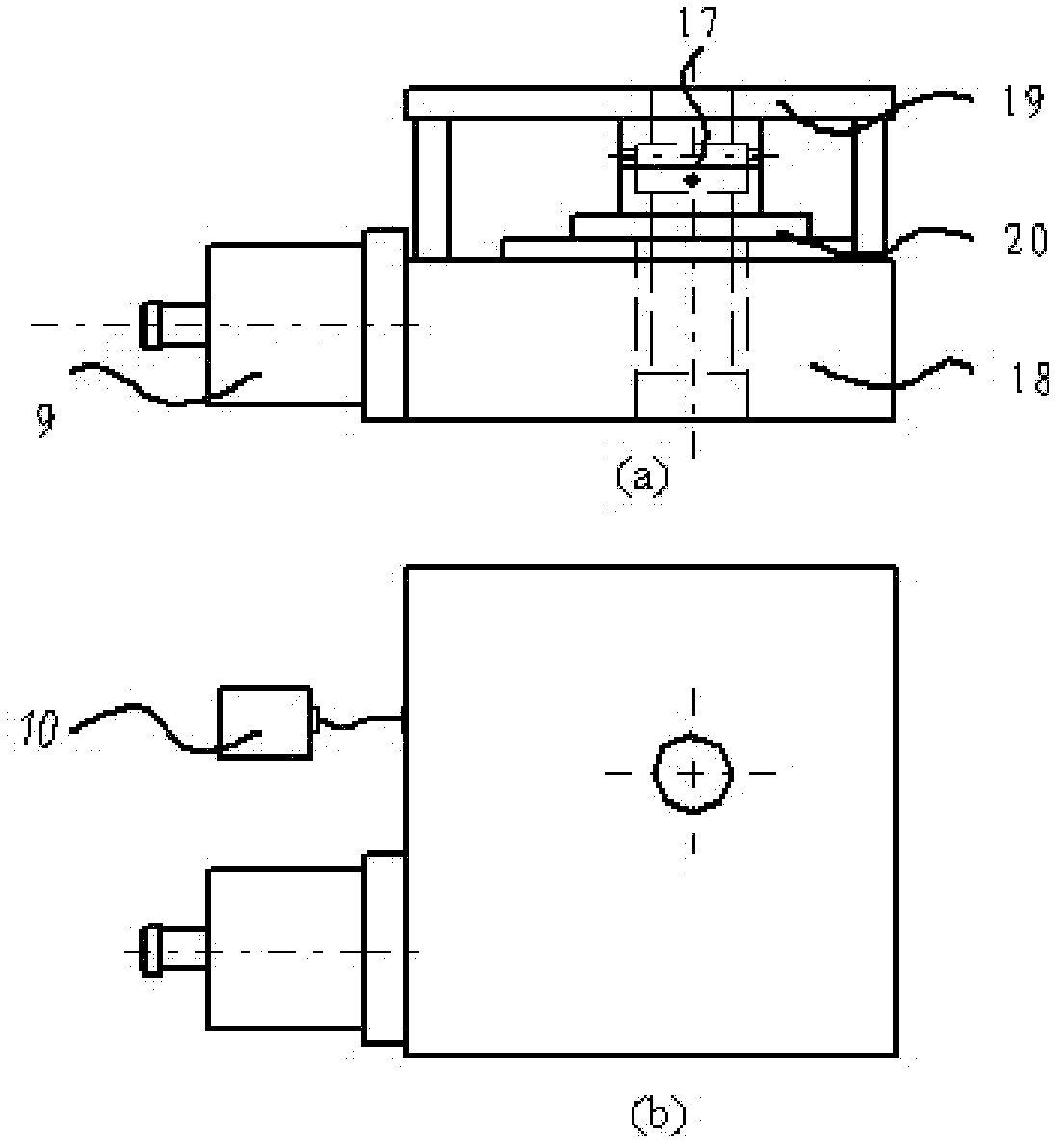

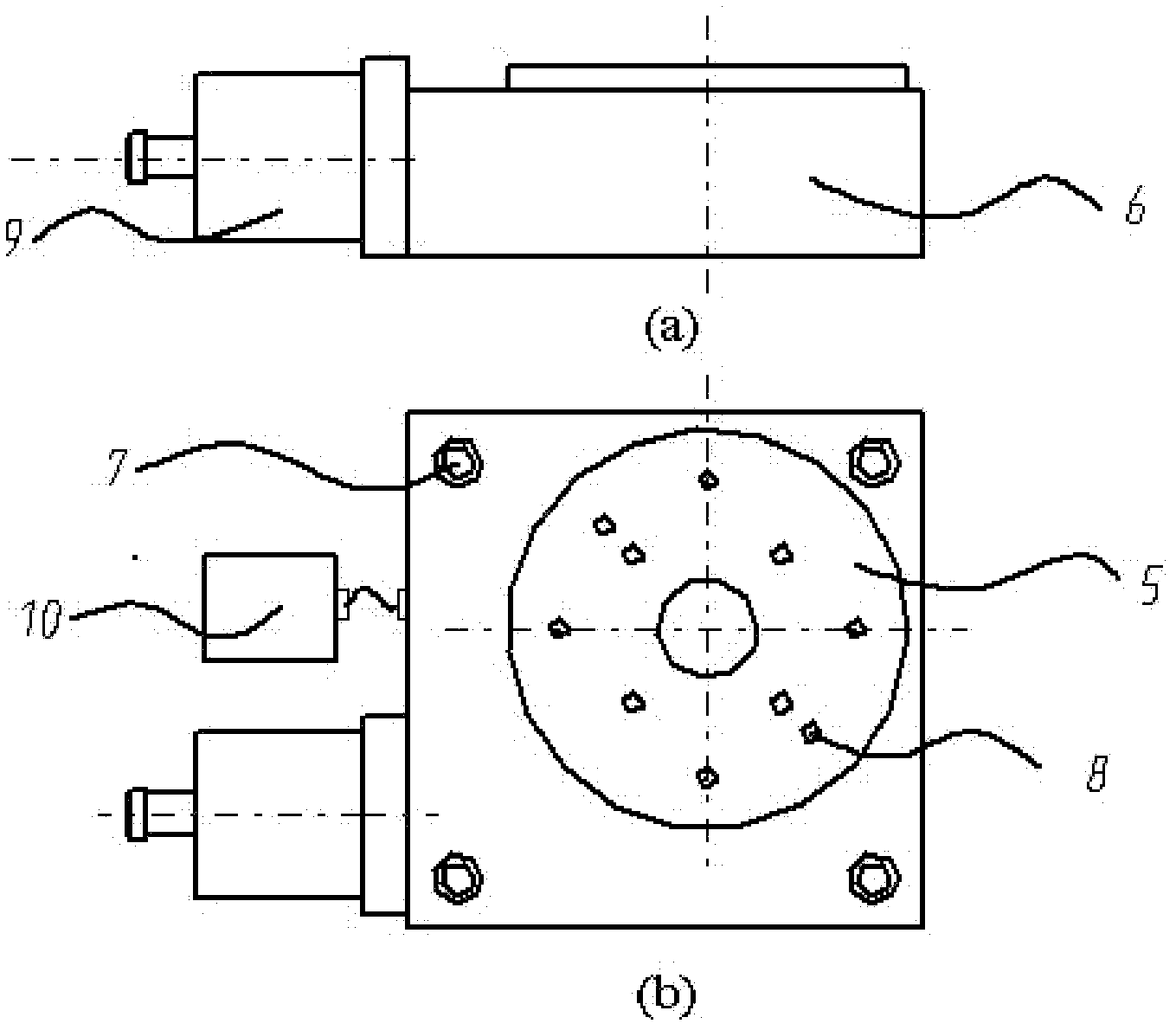

[0022] like figure 1 As shown, the clamping device for aligning the optical axis of the composite wave plate provided by the present invention includes an electrically controlled rotary table 18 , a fixed wave plate chuck 19 and a rotating wave plate chuck 20 .

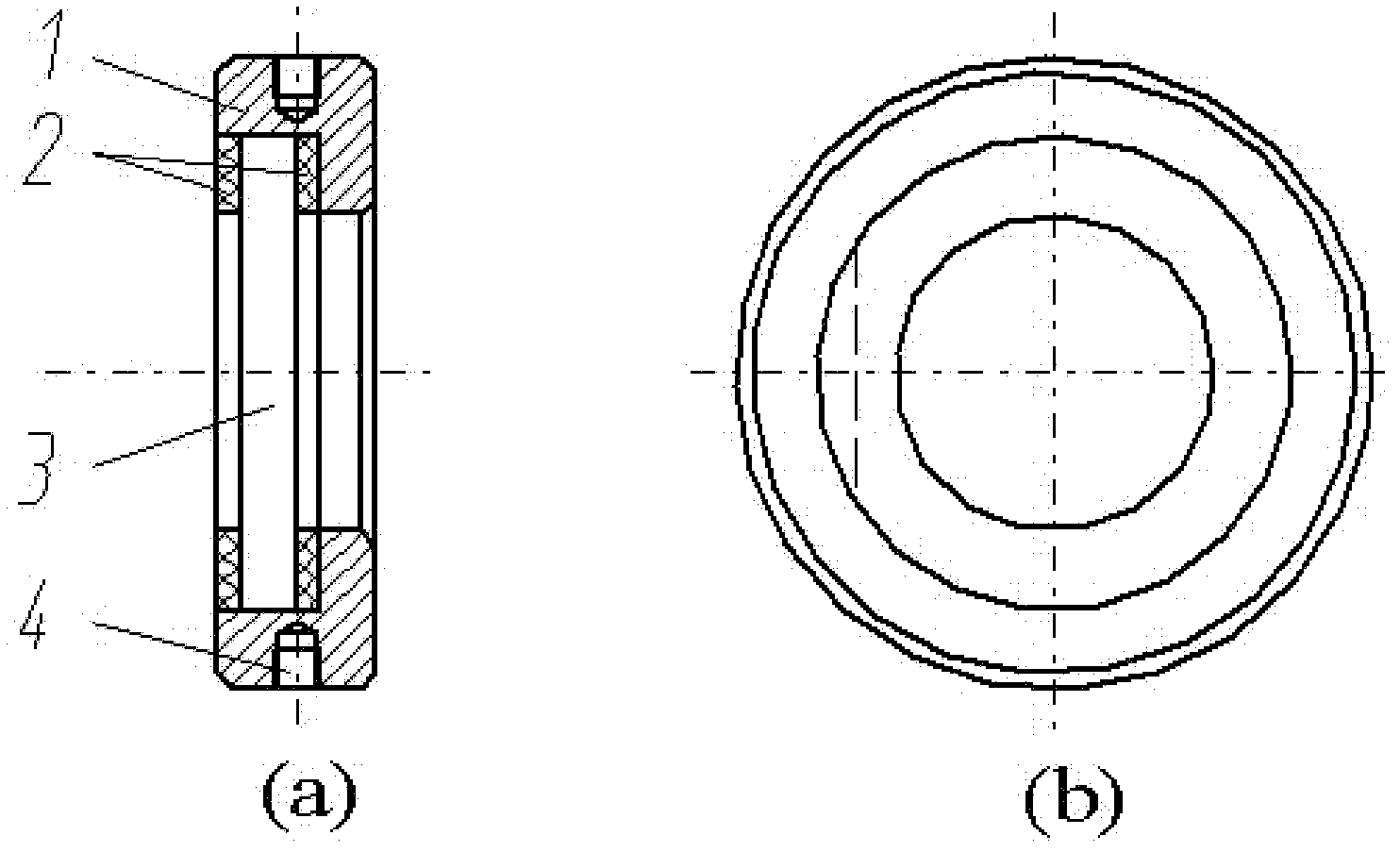

[0023] Waveplates are precision optical components. Usually, the crystal material used to make waveplates is brittle and fragile, and it is easy to damage the chip if it is directly clamped. In order to facilitate wafer clamping, specially designed wafer holders are necessary. The present invention adopts the wave plate support 17 to support and protect the wave plate, so as to facilitate the smooth operation of wave plate clamping and alignment.

[0024] In order to align the opt...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com