Method for quickly acquiring process information of part

A technology of process information and acquisition method, which is applied in the field of rapid acquisition of part process information, can solve the problems of increasing the difficulty of reading data, manufacturing error rate, and difficulty in maintaining data consistency, so as to achieve clear goals and save time for screening information Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

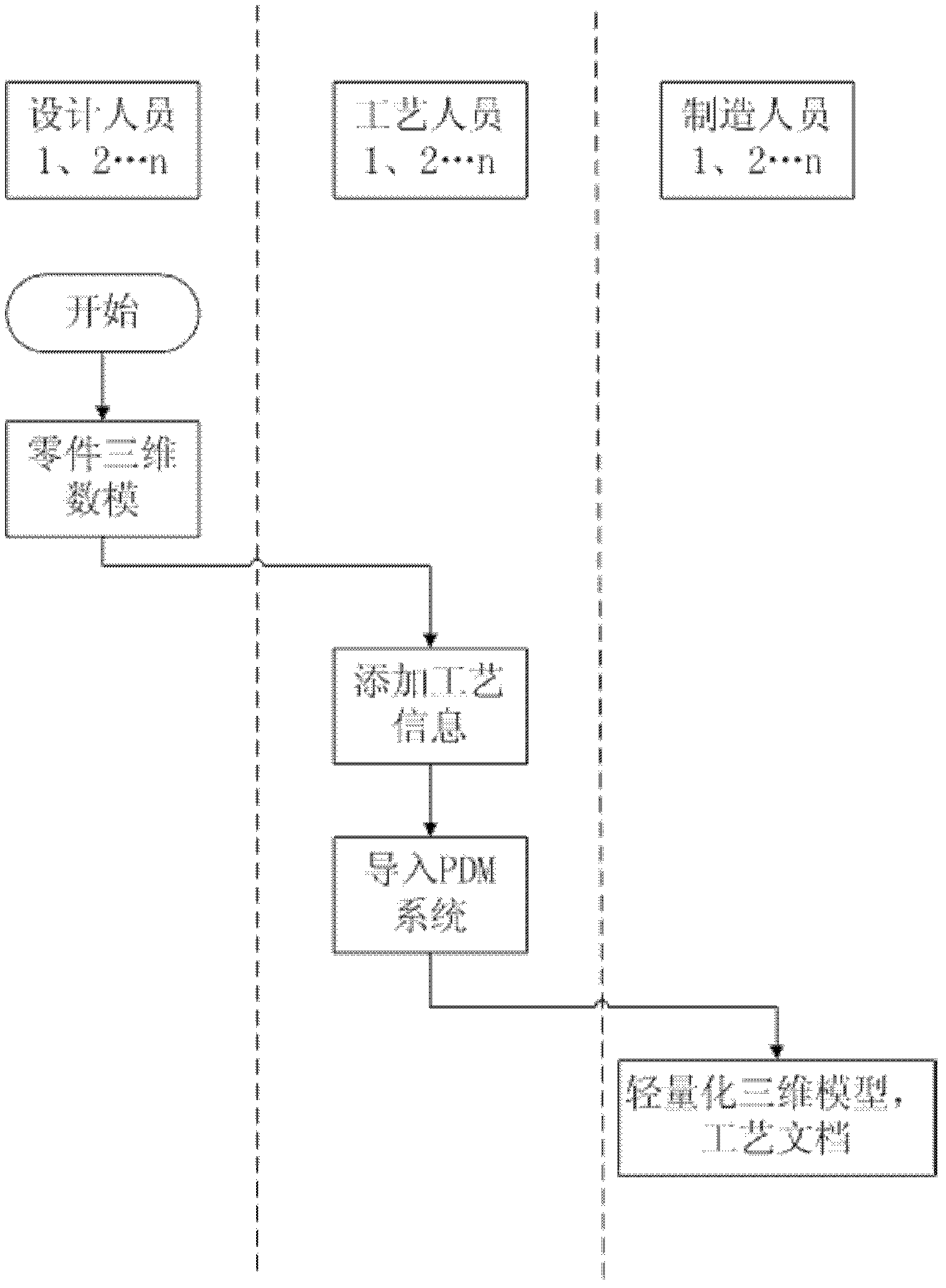

[0024] The purpose of the present invention is to propose a method for quickly obtaining process information of parts. Taking creating a cuboid and obtaining its heat treatment information as an example, the basic steps of its implementation of fast search are as follows:

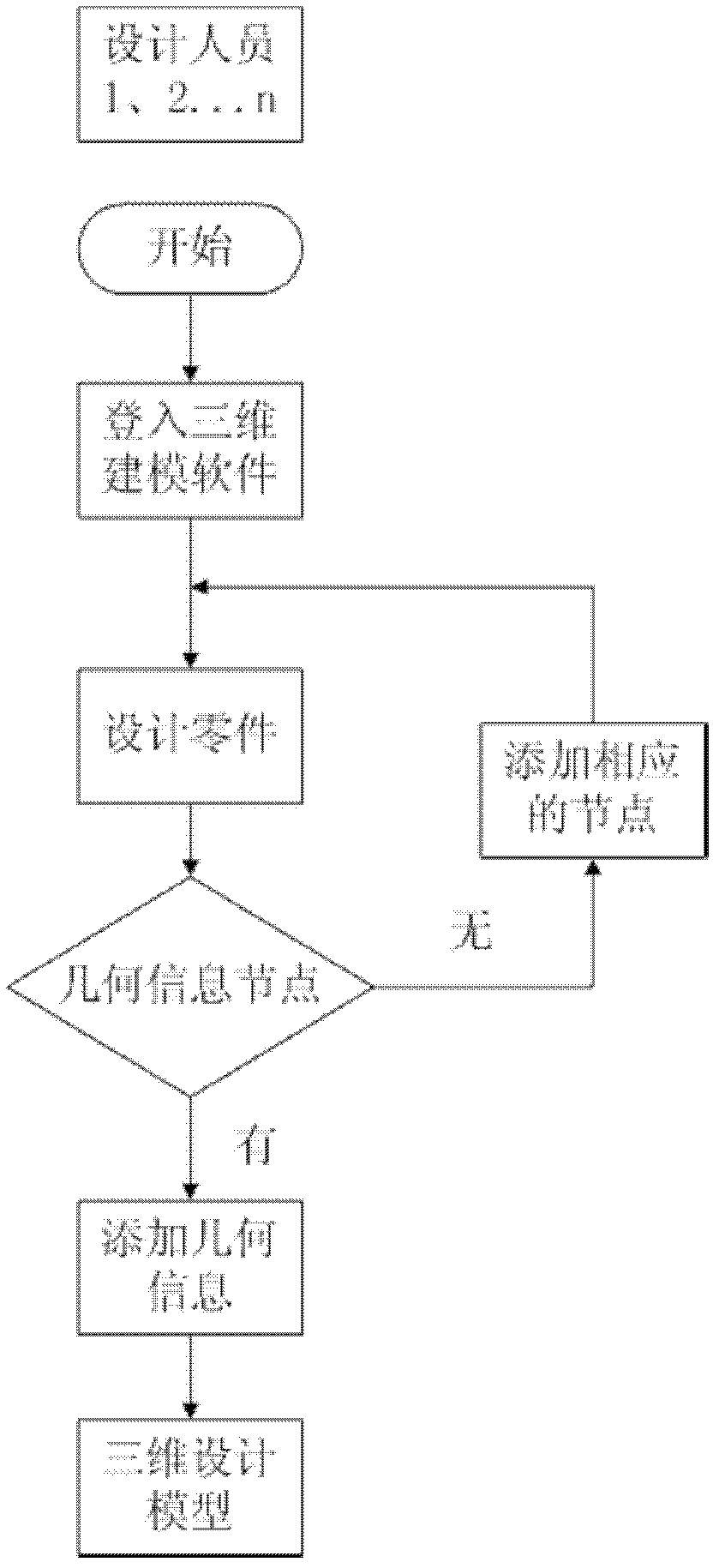

[0025] Step 1: A part designer logs in to the 3D modeling software, creates a rectangle with a length and width of 30mm and 20mm respectively, stretches the rectangle, and the value is 10mm, the modeling of the cuboid is completed, and the geometric information has been successfully added into the feature tree;

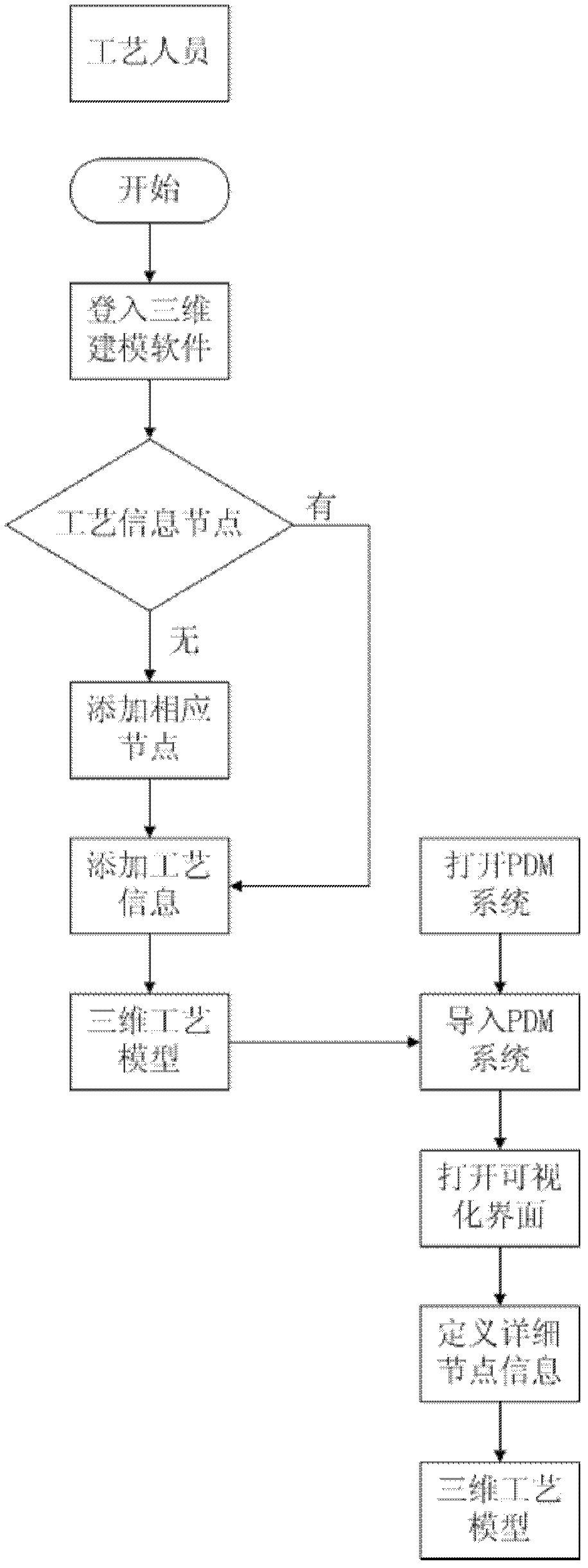

[0026] Step 2: A craftsman logs in to the 3D modeling software, opens the already modeled cuboid, and adds process information to the cuboid, for example, add "Quenching" under the "Heat Treatment" subnode in the "Part Information" node . Select the "Part Information" node, select "Add" in the feature tree information toolbar, and fill in "Heat Treatment: Quenching" in the sub-node that appears un...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com