Induction machine vector control method taking account of iron loss

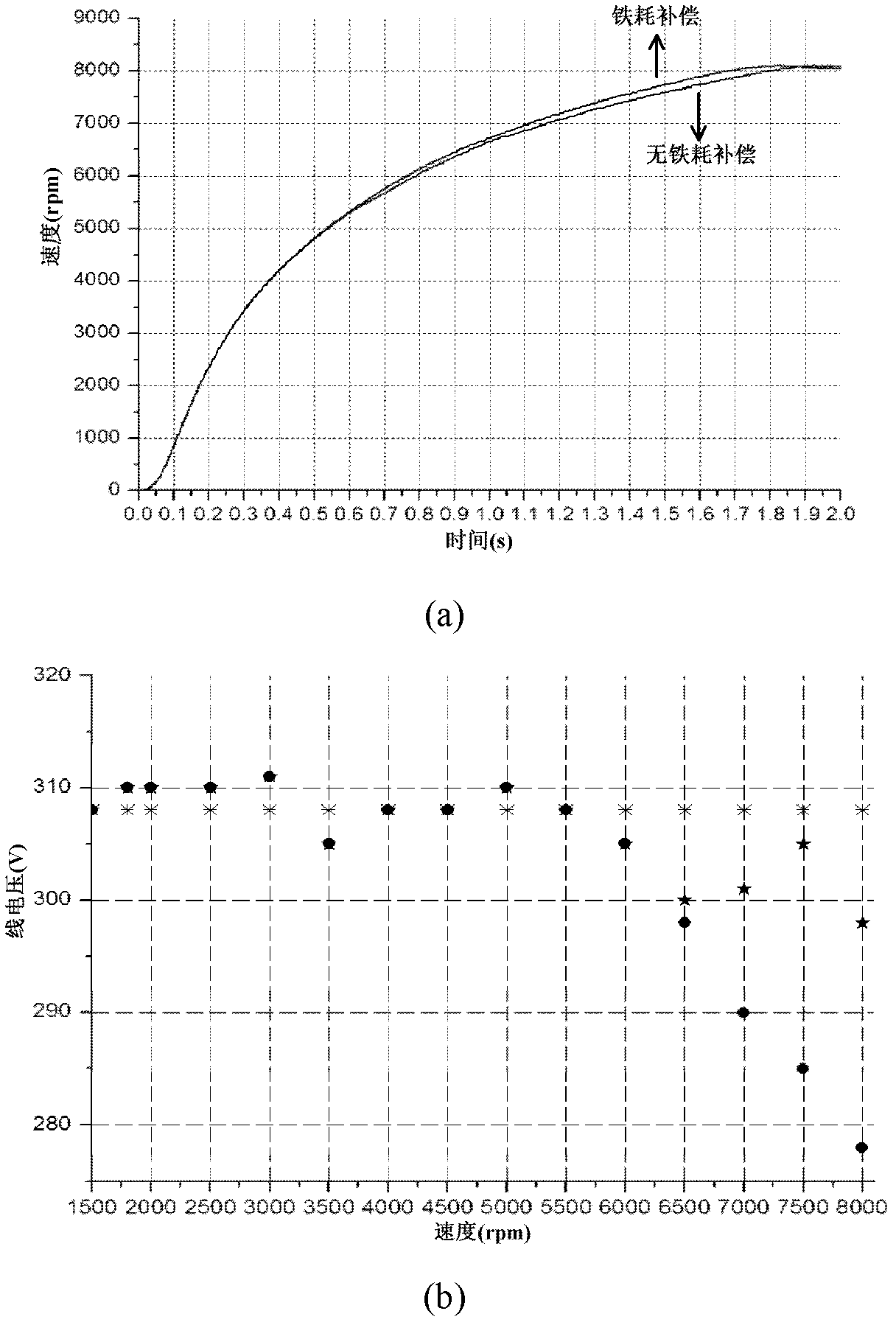

A vector control, induction motor technology, applied in vector control systems, motor generator control, electronic commutation motor control, etc., can solve the problems of inconsistent actual magnetic field size, no consideration of iron loss, and reduced control performance in weak magnetic high-speed areas. , to achieve the effect of enhancing the torque output capability and improving the utilization rate of the current

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

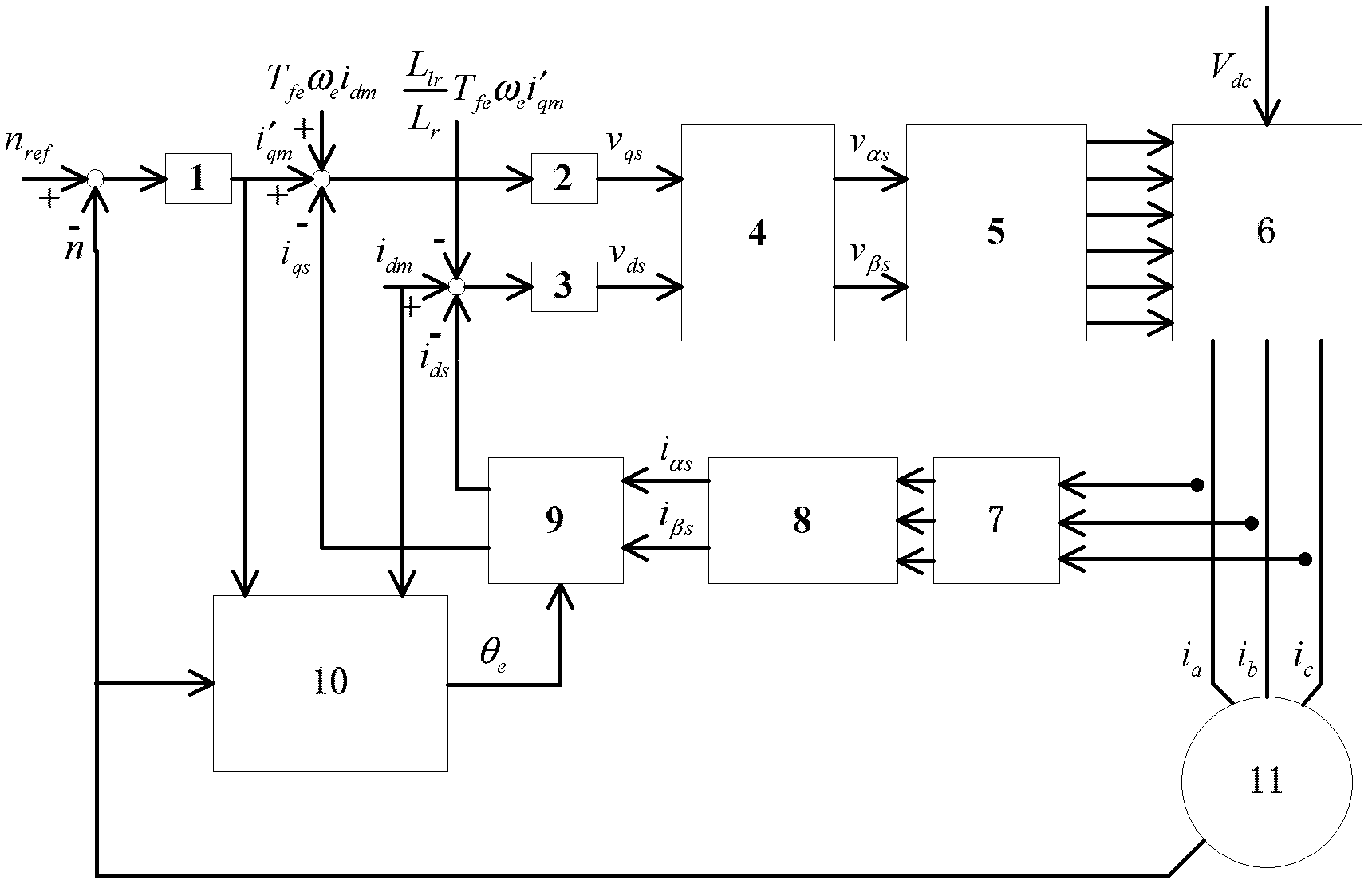

[0015] In order to solve the problems existing in the traditional vector control method, the present invention proposes a vector control method of an induction motor considering iron loss.

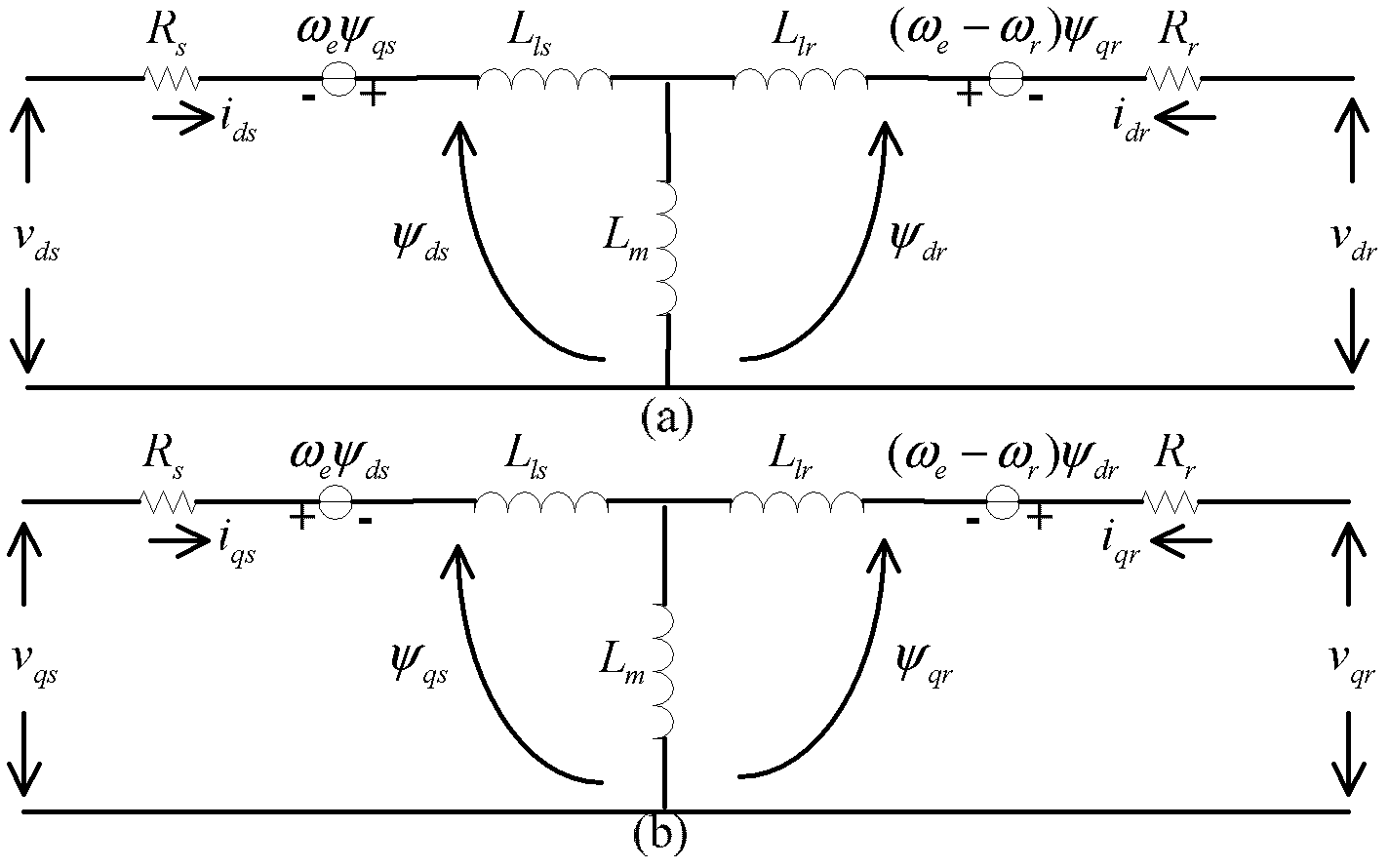

[0016] 1) According to the equivalent circuit of induction motor including iron loss as figure 2 As shown, the derived induction motor vector control has the following expression:

[0017] v ds = R s i ds + dψ ds dt - ω e i qs L ls - ω e i qm L m = R s i ds + dψ ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com