Drinking vessel sealing cover with dual-layer stainless steel vacuum component

A technology for drinking utensils and stainless steel, which is applied to drinking utensils, applications, household appliances, etc., can solve the problems of large water temperature loss, large heat transfer area of hot water, endangering the health of drinking people, etc., so as to ensure drinking safety and ensure drinking safety. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

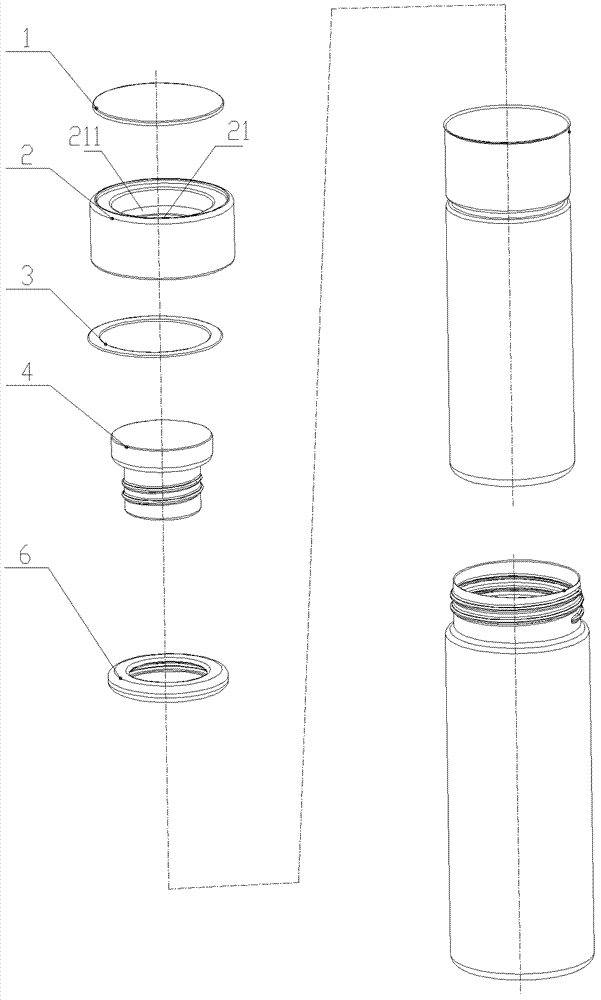

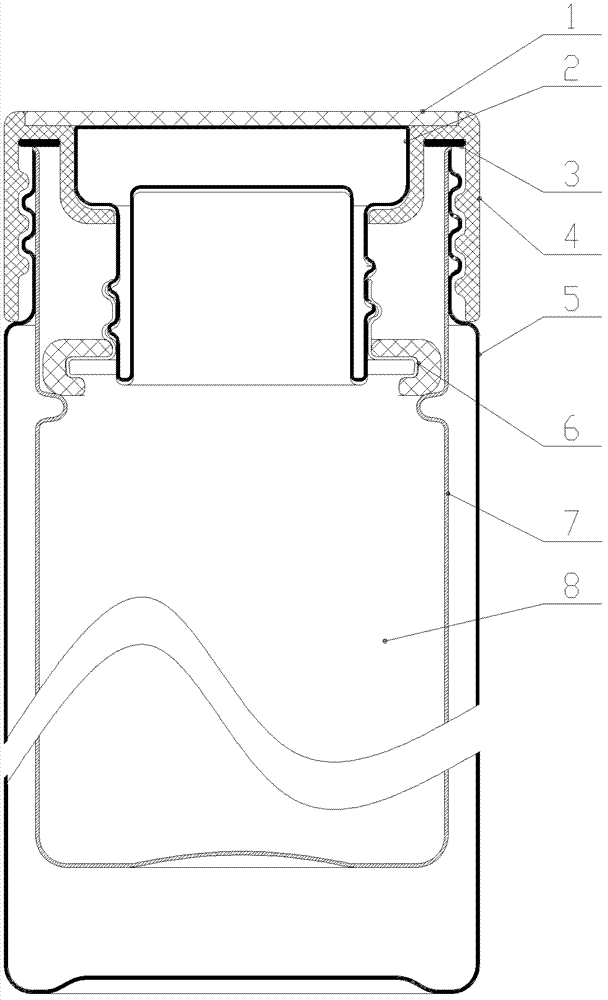

[0031] Refer to attached figure 1 , 2

[0032] The drinking vessel sealing cover with double-layer stainless steel vacuum parts includes a cover body 2 adapted to the cup body, and a first sealing ring 3 is provided on the inner surface of the cover body 2;

[0033] A cylindrical stainless steel vacuum part 4 is fixed on the cover, and the stainless steel vacuum part 4 is composed of a stainless steel outer layer 41 and a stainless steel inner layer 42, and a vacuum chamber is formed between the stainless steel outer layer 41 and the stainless steel inner layer 42 43; the outer wall surface of the stainless steel outer layer 41 of the stainless steel vacuum part 4 is adapted to the vessel cup body A.

[0034] The stainless steel vacuum part 4 is provided with a second sealing ring 6 which is in sealing connection with the cup body A of the vessel.

[0035] The top of the stainless steel vacuum part 4 is provided with an outwardly extending annular protrusion 411, and the co...

Embodiment 2

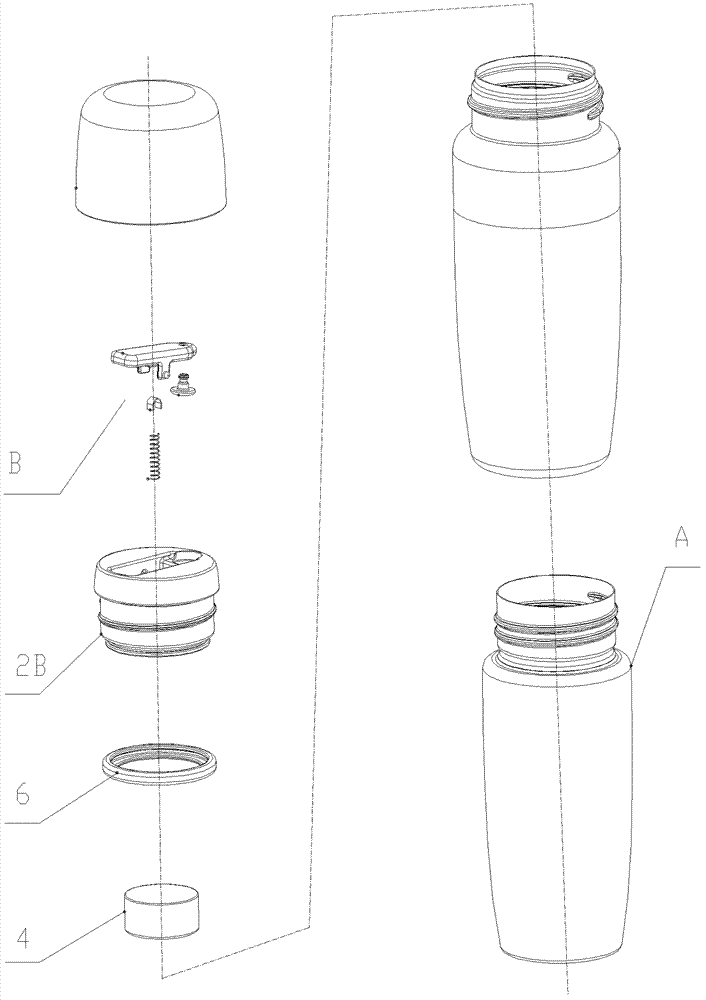

[0043] refer to Figure 3-6

[0044] The drinking vessel sealing cover with double-layer stainless steel vacuum parts includes a cover body 2 adapted to the cup body, and a first sealing ring 3 is provided on the inner surface of the cover body 2;

[0045] A cylindrical stainless steel vacuum part 4 is fixed on the cover, and the stainless steel vacuum part 4 is composed of a stainless steel outer layer 41 and a stainless steel inner layer 42, and a vacuum chamber is formed between the stainless steel outer layer 41 and the stainless steel inner layer 42 43; the outer wall surface of the stainless steel outer layer 41 of the stainless steel vacuum part 4 is adapted to the vessel cup body A.

[0046] The stainless steel vacuum part 4 is provided with a second sealing ring 6 which is in sealing connection with the cup body A of the vessel.

[0047] The cover body 2B is provided with an accommodating chamber for accommodating the cylindrical stainless steel vacuum part, and the...

Embodiment 3

[0052] refer to Figure 7-8 , as an example for the lid of the externally rotating straight cup and the internally rotating thermos jug with a switch, in detail:

[0053]The difference between this embodiment and Embodiment 1 is that the stainless steel vacuum member 4 is connected to a filter screen 5 capable of holding tea leaves and other seasoning materials, and the top of the filter screen 5 is provided with an internal thread 51, and the The stainless steel vacuum part 4 is provided with a filter screen external thread adapted to the filter screen 5 internal thread 41. The rest of the structures are the same.

[0054] The technical concept of this embodiment is: connect the stainless steel vacuum part 4 with the filter screen 5, connect the cup cover with the filter screen 5 as a whole, when brewing seasoning materials such as tea, you only need to put the seasoning material into the filter screen 5 , After covering the cup, the seasoning material is immersed in hot wa...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com